CIMdata is a leading independent global strategic management consulting and research authority focused exclusively on PLM and the digital transformation it enables. I had an opportunity to discuss OpenBOM development with CIMdata. The main topic in our discussion was “digital thread”, but we also touched on many topics related to OpenBOM customer development.

One of the main principles of product lifecycle management is to connect various sources of information throughout the end-to-end product data life cycle. Manufacturing data typically interconnects through multi-view bills of material (BOMs), which truly become the lifeblood of product development, from early engineering phases to manufacturing, production, and maintenance. If you’re coming from this space you might be familiar with multiple BOMs – as-required, as-designed, as-manufactured, as-built, and as-maintained BOMs. According to Peter Bilello of CIMdata, Digital Twin without a Digital Thread is an orphan”.

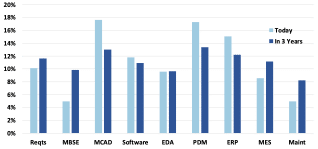

For more than twenty years, CIMdata has spoken about a bill of information (BOI), an expansive, associative virtual data store built around the bill of material (BOM), which evolves from idea through life, and includes associated information that supports lifecycle processes, e.g., documented product requirements, early and final versions of the design, assembly and maintenance instructions, and virtual and physical test results. These are but a few types of information that manufacturing companies want to manage as part of their digital thread, which builds on the BOI concept and has gained credibility in many industrial sectors. In a recent survey, CIMdata asked industrial respondents about their plans to manage disparate knowledge as part of their digital thread.[1] The picture below represents the current state of the digital thread at our industrial respondents and their expansion plans over the next three years. Mechanical computer-aided design (MCAD) is often managed using product data management (PDM) solutions, and both are rated highly. And the transition of the engineering BOM (eBOM) to the manufacturing BOM (mBOM) usually managed in an enterprise resource planning (ERP) solution, was also highly rated.

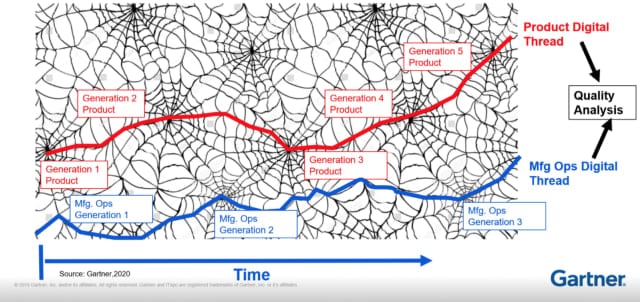

There are multiple digital threads and each of which is contextual to the organization and its processes. The organization can also have multiple digital threads depending on what they do. These digital threads are extremely important for enterprise process integration. Marc Halpern of Gartner in his presentation at CIMdata PLM Roadmap 2020 presented the future of digital thread with the following subject- “Digital Thread: Be Careful What You Wish For, It Just Might Come True.”. Halpern referred to “digital nets” that can combine and connect digital threads that evolve over time. According to Gartner, it is a process that increasingly happening in many organizations these days as a result of digital transformation and M&A activities.

At OpenBOM we embrace the vision of digital transformation and digital thread creation and combine it with the vision of OpenBOM web services and global BOM graph, which is the foundation of distributed digital thread that can connect multiple companies working together. Such a global BOM graph is a foundation of the OpenBOM online platform and provides a unique data management platform that within time will be capable to produce product data intelligence and analytics to support the company’s decision-making process. OpenBOM platform is using modern data management architecture including noSQL databases and Neo4j, a leading graph database, to scale up OpenBOM web services and use it as a flexible platform for PLM data modeling.

Read CIMdata commentary here – OpenBOM: Spanning the Digital Thread Cloud-native offering expanding lifecycle coverage (Commentary)

Key takeaways by CIMdata.

- The concept of the digital thread has become important to many industries, expanding well beyond its roots in discrete manufacturing.

- The Bill of Material (BOM) is at the core of the digital thread, and the nexus for information that industrial companies want to associate with the BOM as it evolves from idea through life.

- OpenBOM, a recent entrant into the market, offers a cloud-native, multi-tenant solution that helps companies and their value chain partners collaborate around the BOM.

- OpenBOM’s customers have started to expand their use of OpenBOM’s delivered capabilities into use cases more typical of other enterprise software such as ERP and PDM.

Conclusion

Digital thread concepts go back to the original PLM definition and the need for companies to connect, manage and share information. Modern manufacturing is expanding and turning into a digitally enabled network that requires information infrastructure to run their businesses. CIMdata research has shown that industrial companies have an expansive view of their digital thread so offerings purported to support the digital thread must be able to support a wide range of data types and use cases that might span enterprise software segments.

REGISTER FOR FREE to check out how OpenBOM can help you and your team today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.