As manufacturers move towards Industry 4.0 and the digital age, the “digital thread” has become a key concept to enable the continuing evolution of production. The digital thread is the backbone that ties together all aspects of manufacturing and allows for efficient communication between machines, humans, and software. To take full advantage of Industry 4.0, manufacturers must embrace the digital thread to achieve enhanced productivity, quality, and security. Though there are some challenges to implementing a digital thread, the benefits are clear and it is becoming increasingly important for manufacturers to do so.

Moving from Documents To Data and Digital Thread

File-based approaches and data management systems focused on files and their derivatives were growing up naturally for the last few decades in the engineering software space – CAD, PDMs, PLM systems. These systems were growing and became important for many manufacturing businesses. But all these systems have a fundamental flaw. The main problem of the approach is to maintain documents as a unit of information that must be managed. Then the problem of data consistency and connectivity comes immediately. Eventually, companies need to work with many systems and each of them presents its own needs to the files and might need to save different information. Which immediately makes the file-based approach questionable. There are many examples of inefficiency related to file-based systems.

The digital thread is redefining how manufacturers work with data. By integrating data throughout the product lifecycle, the digital thread enables companies to make better decisions, improve product quality, and speed time to market.

As manufacturers move towards digital transformation, the “digital thread” has become a key concept to enable the continuing evolution of production. The digital thread is the backbone that ties together all aspects of manufacturing and allows for efficient communication between machines, humans, and software. To take full advantage of digital transformation, manufacturers must embrace the digital thread to achieve enhanced productivity, quality, and security.

Multi-Tenant SaaS Platforms – A Backbone for Digital Thread

For many years, the PLM foundation was a single database – DB2, Oracle, MS SQL, etc. It was the most mature technology PLM companies were able to rely on and it needs to be approved by the IT of large companies. So, the solutions will be using these DB as a foundation of their architectures in the 1990s and 2000s.

Three things happened since then that changed the approach and system architecture:

- Cloud – you don’t need a customer to deploy a system. The architecture of the system can be improved, company IT doesn’t have to own it.

- Data Management – A database is just a tool and SQL is not the best database for everything systems need to manage.

- Multi-tenancy – mainstream systems were not designed to help multiple companies to work together. Those systems were designed for a single company, not for a network – the future organization of enterprise and industry 4.0.

As a result, the new type of enterprise systems – multi-tenant SaaS platforms are coming to replace traditional mainstream single database-driven enterprise PLM systems. Those new platforms rely on a polyglot persistence data management architecture, micro-service architecture, and new collaboration capabilities to help manage information flows between users and companies.

OpenBOM and Digital Thread

The foundation of the OpenBOM data platform is data. OpenBOM provides flexible data objects to define items, bills of materials, orders, vendors, and purchase orders. Using structured data properties and relationships, OpenBOM supports core product information data modeling and semantic relationships between data elements. Instant data sharing combined with user-defined team views is a foundation of the data-sharing mechanism. Data can be shared with the maximum level of granularity.

You can say it about almost all cloud-native platforms, but here is a big difference that you will find when you check OpenBOM deeper. The core difference in OpenBOM is a multi-tenant data model capable of bringing data from multiple companies and connecting it together.

If you haven’t had a chance to hear about OpenBOM Global BOM Graph, this is an opportunity for you to learn more about it. In my earlier article this week, I speak about how such a data foundation can put you ahead of disruption in manufacturing.

This should be a wake-up call for everyone. So, called data gaps are real and industrial companies should be looking at how to fill the void of the data gap. Industrial companies are looking for platforms that can bring “linking capabilities” and the OpenBOM platform is the best platform for a digital thread in the industry. Stay tuned- we will talk about it more next week.

OpenBOM provides you with a set of online services to manage information flow.

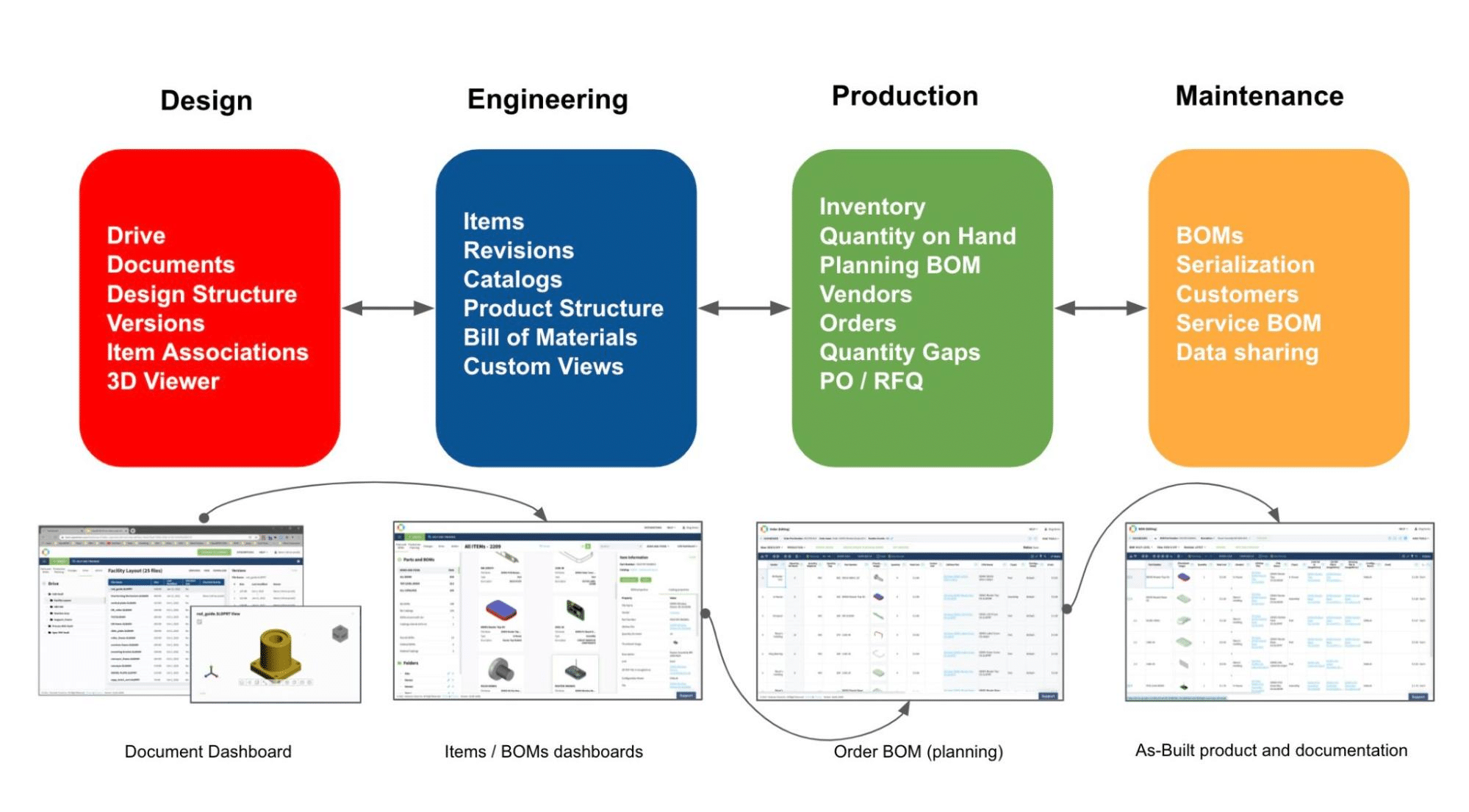

With OpenBOM, companies can build a digital thread that improves communication and collaboration between suppliers, designers, engineers, and manufacturers. In our recent article, I talked about how the new OpenBOM Drive extends the digital workflows for customers using OpenBOM by adding an ability to bring CAD (and other files) under control and associate catalog item records with files located in Drive. Today, I want to give you a bigger picture of how OpenBOM manages the information and connects the silos.

Read more about how you can build a digital thread using OpenBOM online services.

Conclusion

In modern manufacturing, your data will end up in the digital thread. We moved from document vaults and single PLM databases. The data must be connected and companies will have to manage how to optimize the information flow and not how to store all data in a single place.

OpenBOM provides a set of robust services that can help you organize your digital information flow, extract data, share, transform and make it connected and available across the digital thread. The information managed by OpenBOM is intertwined and OpenBOM collaborative tools provide an easy and simple way for people to perform their tasks and communicate. All together, OpenBOM data platforms allow the creation of a connected information set, which helps to streamline processes and information exchange.

Check out how OpenBOM can help you – REGISTER FOR FREE and start a 14-day trial today.

Best,Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.