Change management is one of the most complex disciplines in the organization of product development and manufacturing. The biggest challenge is to keep developing and manufacturing while providing formal change management control. In a nutshell, the challenge is to keep pace with change. New product designs, evolving customer demands, and the ever-changing global market all conspire to require constant adaptation. That’s where collaboration comes in – working together across departments and even companies to identify and act on opportunities quickly. But that’s easier said than done, isn’t it? To keep track of changes you need to control every single operation and keep the history of who did what, when, and why. To collaborate, you need to allow multiple people and teams to work together.

Change Control and Collaboration – Conflicting Forces?

Manufacturing companies are looking at how to combine two processes – product data management with full control of change processes and collaboration capabilities. Product Lifecycle management companies were focusing on solving these problems for ages. The PLM industry first came into configuration management, which allowed manufacturing world methods of managing data elements in PLM systems and providing formal control of changes through the entire lifecycle. A typical PLM system manages product data and controls every change but makes it so hard for users that it quickly becomes a “data recording” system where data can be stored for historical records. To work, companies are exporting the data to Excel, making changes, and then re-importing it back. This means zero collaboration and complex communication.

Collaborative Workspace –

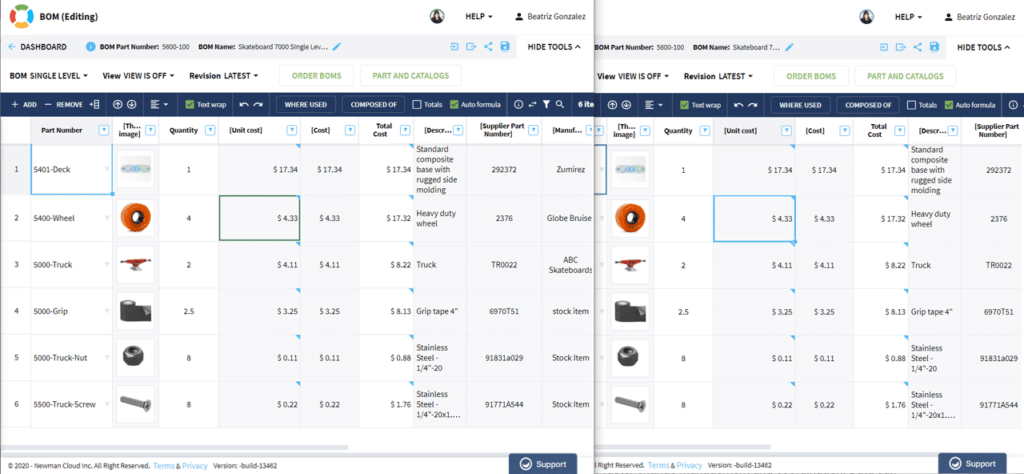

At OpenBOM, we decided to turn things upside down and develop an easy way to share structured data elements allowing users to work together and make changes. When you edit data in OpenBOM, you essentially work in the “latest state” where all users with access to the data can get and make a change. OpenBOM will automatically keep the track of changes. The “latest state” is becoming a common shareable space where editing can be done easily and almost without restriction.

In the picture below you can see a simulation (between two browsers) of how two users can make changes in the same Bill of Materials.

Latest State vs Revision Control

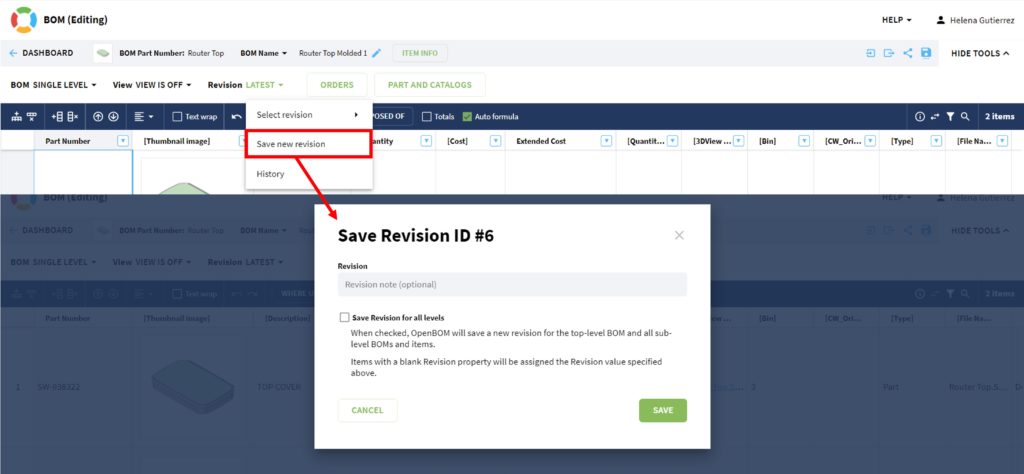

The next layer after “Latest State” is the revision. A revision is an immutable snapshot captured from the “latest state” and saved separately to provide a baseline that can refer to a specific “revision”. OpenBOM allows managing revisions for both Items and (if an item is an assembly) also the Bill of Materials. OpenBOM functionality supports connected revision lifecycle processes that allow for the preservation of the history and relationships between revisions in a structured data management method.

Conclusion

OpenBOM is a cloud-based platform that helps you manage product data across teams and companies, making collaboration faster and easier than ever before. The foundation of the OpenBOM collaborative platform is a technology that allows the organization of a collaborative workspace where structured product data can be presented in an easy and intuitive fashion allowing multiple participants to make changes simultaneously, while OpenBOM is capturing the history of changes, manage revisions and provides a controlled workflow to approve changes. OpenBOM provides a very unique user experience using an intuitive “Excel-like” paradigm. In such a way OpenBOM makes complex things simple and allows us to support both real-time collaboration and change management together.

REGISTER FOR FREE to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.