There is no single manufacturer in this world now that is not experiencing challenges with supply chain management and sourcing components these days. We are hearing it from our customers and prospects every day. We found that diversification of your supply chain is one of the most important things to avoid manufacturing pitfalls in 2022.

The pandemic has highlighted certain risks of only having one supplier. Consolidating into one supplier leaves your company vulnerable if that supplier goes out of business or policies change that makes it more expensive to purchase from them.

Optimizing Supply Chain and Multiple Purchase Orders

For each part you procure, you should have a few backups that are ready to receive and place orders if needed. These suppliers should also be in different regions. So, if you are fabricating one part in China, why find another supplier in China? This doesn’t help when certain political policies are in place. To diversify, look at different regions. Look for suppliers in your home country, re-shoring, or to a country close to yours, near-shoring.

To diversify your supply chain and to manage multiple sources of supply you need to be able to manage these multiple suppliers and their orders and still calculate the overall balance of quantities on hands you have for your production or even prototyping activities.

Multiple concurrent purchase orders can be a headache to manage in every engineering team, prototyping activity, and manufacturing company. Trying to do it using Excel will lead you to a failure and we’ve seen it with many companies coming to OpenBOM. OpenBOM gives you an elegant and simple way to streamline your engineering to the production process and helps you manage vendors, multiple suppliers, and purchases, to consolidate the data about items and stock levels.

In this article, we’ll show you how to make the most of OpenBOM’s features to streamline your purchasing process. OpenBOM will help you to stay on top of your inventory and keep your production line running smoothly.

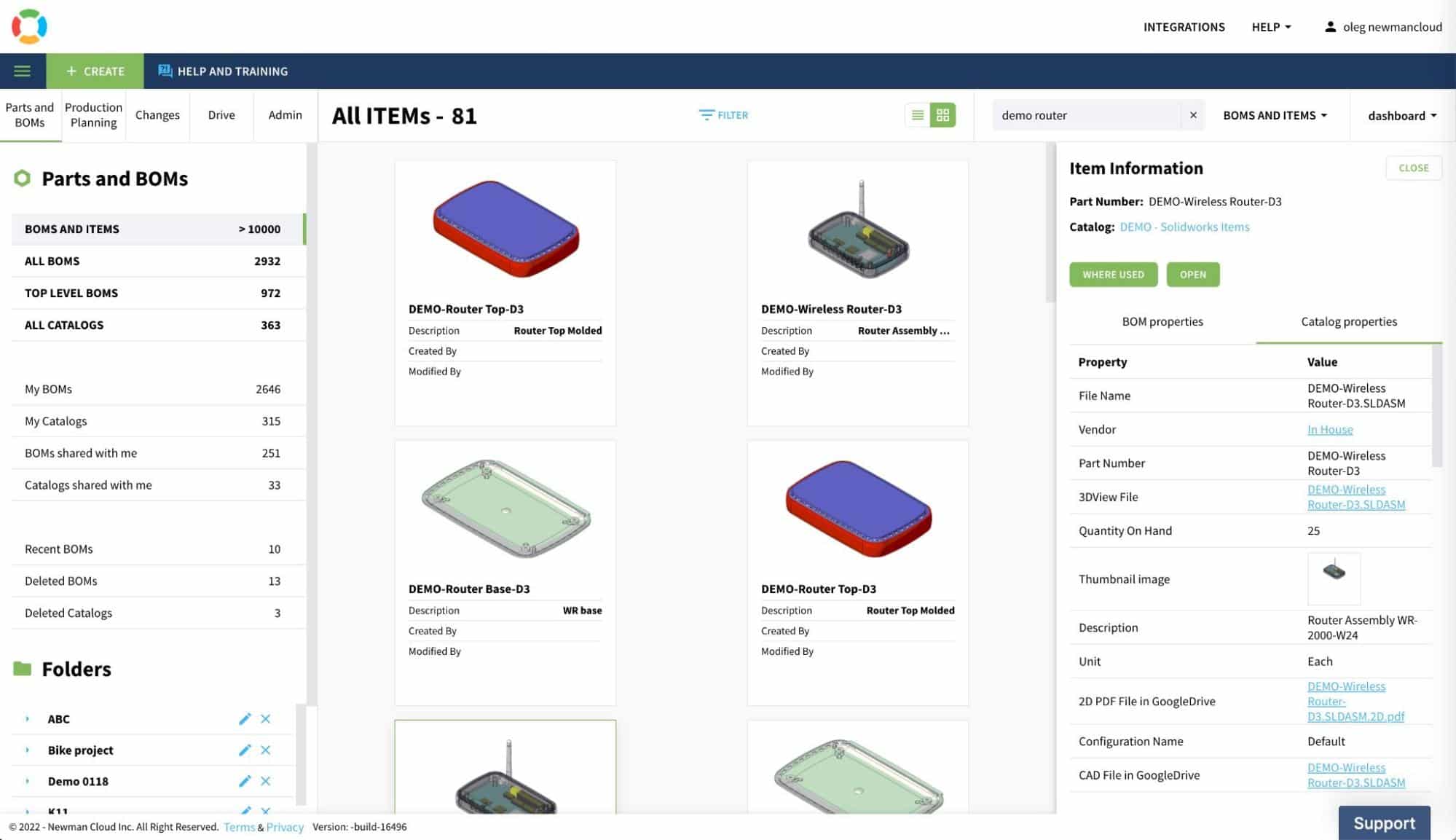

In my example, I will use the demo data we have at OpenBOM for a wireless router.

Catalogs and Vendor Lists

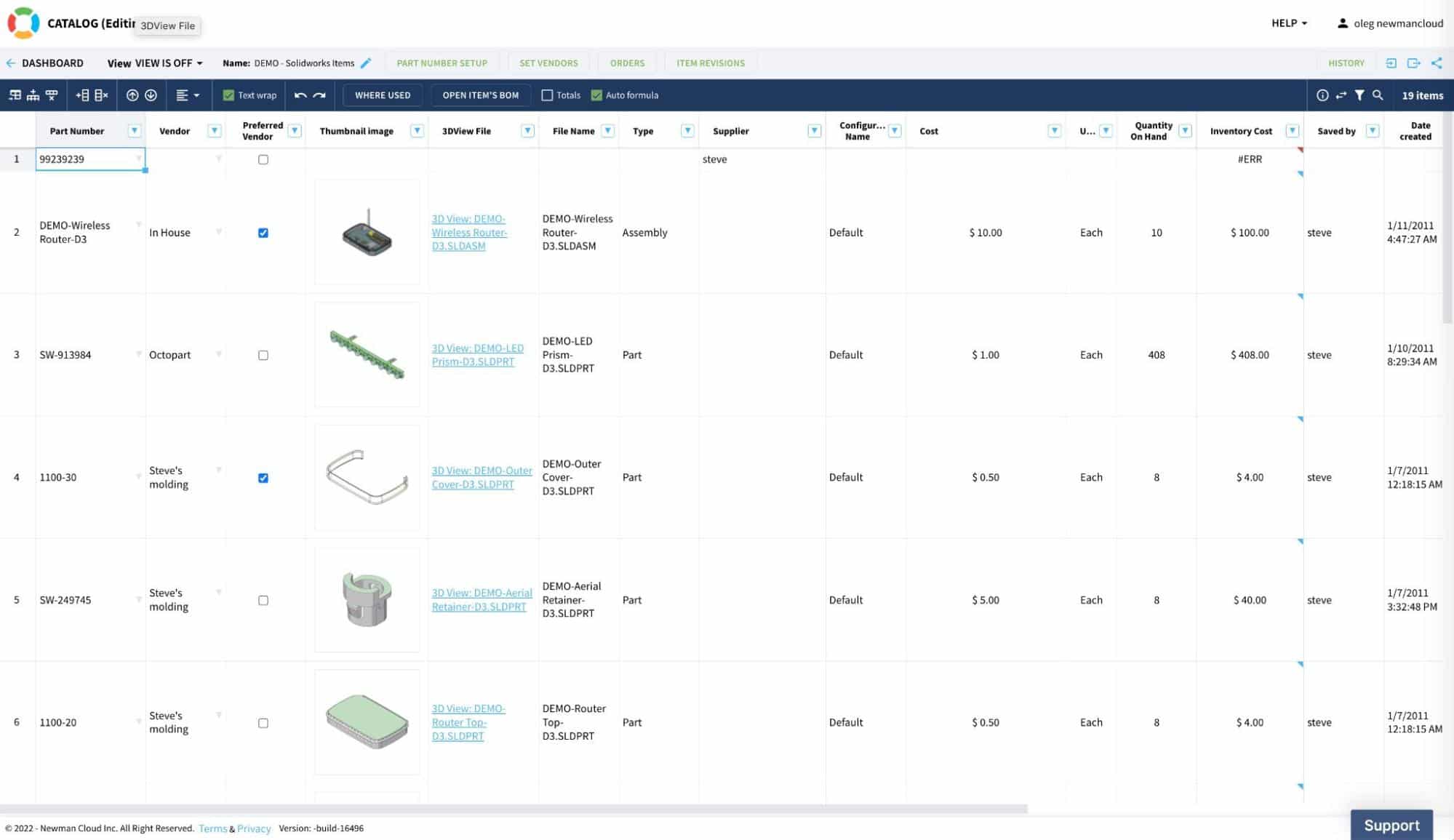

OpenBOM catalog is a database of item masters you manage to represent all data in OpenBOM about what you buy, make, or assemble. A typical OpenBOM account will have a set of catalogs to classify all components into groups (eg. products, mechanical, electrical, electronic, etc.). You can be more granular, but I’m sure you’re getting the idea.

An important element of the OpenBOM catalog is Part Number, Vendor, and Quantity On Hand. In addition to that, OpenBOM allows you to add any number of custom properties you want to the item (eg. to indicate availability, lead time, cost, etc.)

Quantity on Hand is the key value that helps OpenBOM to calculate the gaps for planning purposes. So, when you create a planning BOM (see below), the gaps will be calculated automatically.

The vendor is another parameter that helps you to select where you buy this item. The most important function is that the Vendor can be set in the catalog and later to be redefined in the Planning (Order) BOM. This is the key function you need to know. See the picture below. You can define ANY vendor in the order you need to order from.

Planning BOMs (Orders) and POs

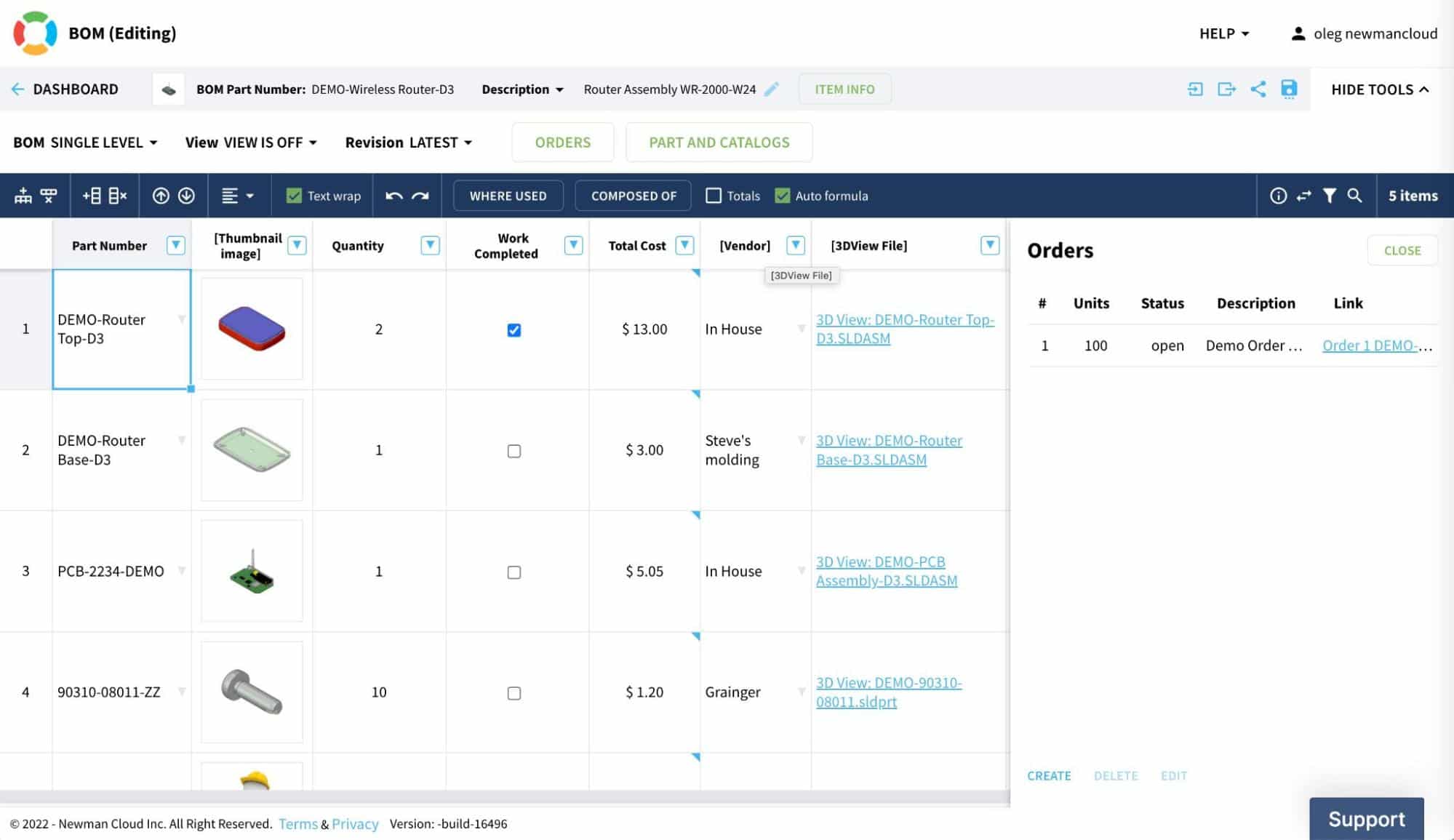

Order (or Planning BOM) is the list of materials created either based on the BOM or arbitrarily from the catalog by selecting a list of components and clicking on the Order command. Below you can see an example of the Order created from a specific BOM as well as another Order that is created directly from the catalog.

Here is an order panel allowing you to create an order for the entire BOM.

Once you’ve done it, you will have an order with all components you need for 100 units of the wireless router.

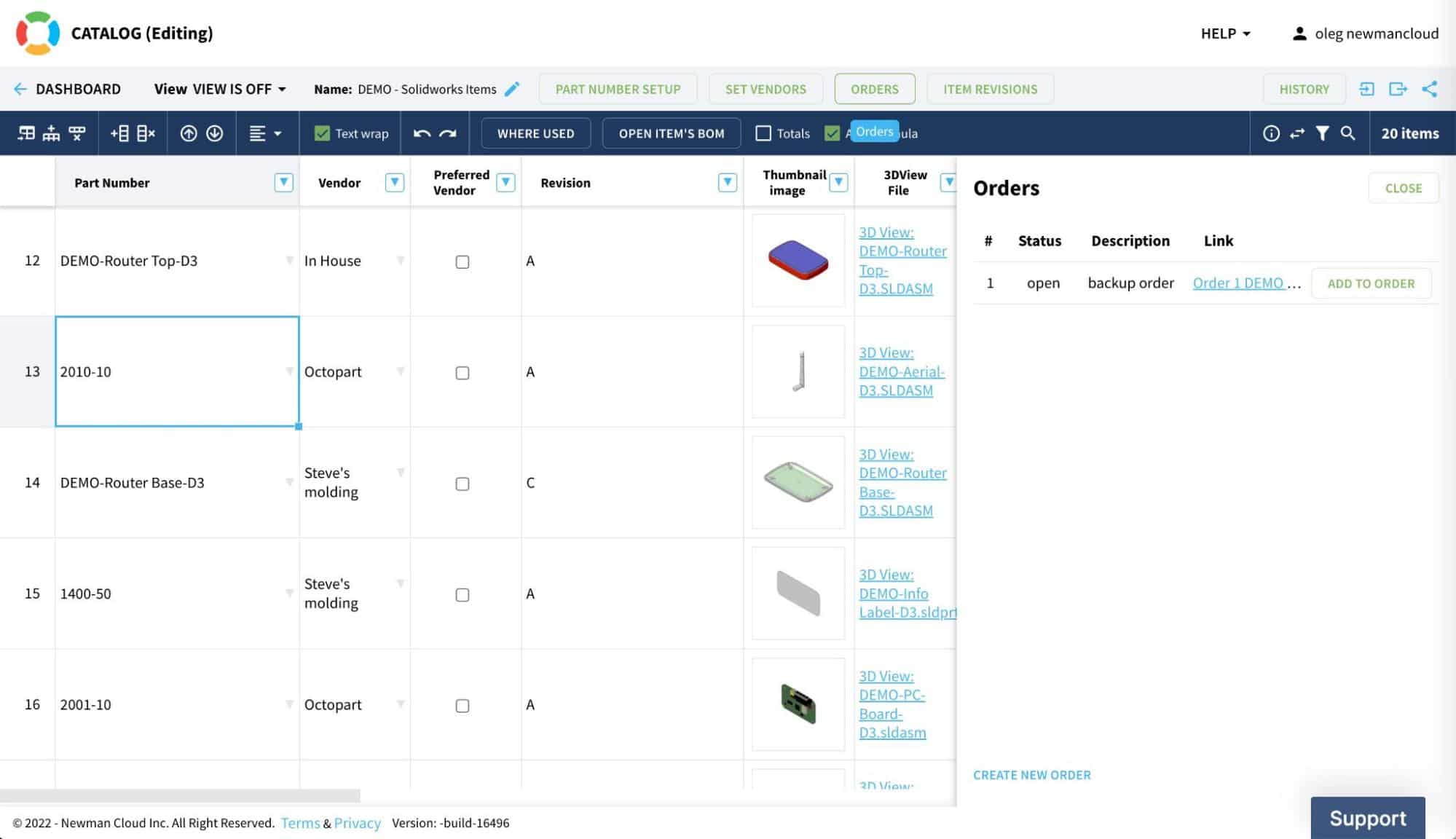

Now, let’s say one of the suppliers cannot ship you the part and you need to create another order to backup your original order. Here is how you can do it by navigating to the catalog, picking up the item, and clicking on the Order button to create a backup order.

Concurrent POs and Partial Receive Function

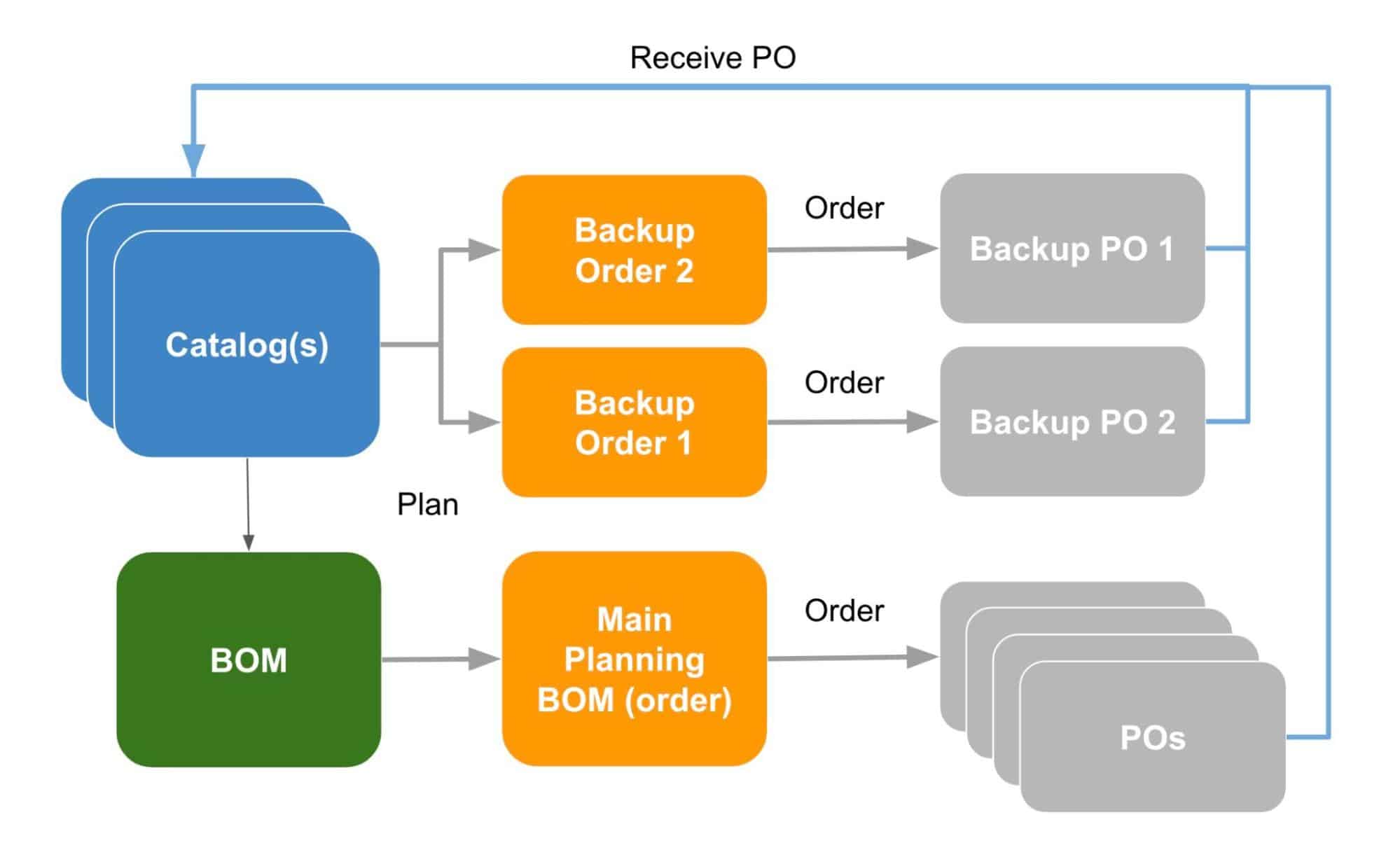

The power of the OpenBOM purchasing mechanism is that you can create multiple orders and generate POs for different vendors without impacting the planning process. Multiple POs can stay open in the PO dashboard and once you get it from the vendor, you can use the “receive PO” function to accept the PO and update “Quantity on Hand”.

So, in a situation where you have to entertain multiple sourcing options, creating multiple orders and placing POs to multiple vendors is the best strategy and OpenBOM supports it by creating multiple orders.

In the diagram below, I illustrate the idea of parallel orders and updates of the catalog based on a selective receive PO functionality.

Conclusion

Diversification of the supply chain is one of the biggest challenges for manufacturing companies these days. OpenBOM provides a simple, yet powerful mechanism to manage the sourcing activity helping manufacturers to perform multiple orders and balance their receive functions with continuous updates.

Are you struggling to manage multiple orders to ensure you have enough stock to manufacture or assemble your products? Then check out how OpenBOM can help you today.

REGISTER FOR FREE and start a free trial for 14-days to check all functions.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.