Configuration management (CM) is a complex discipline that includes methodology and tools to control the consistency of all processes related to product definition, planning, maintenance, and support. I recently read a few very good articles about modern trends in configuration management driven by the growing complexity of products, switching from predominantly mechanical design to methods and tools allowing management of mechanical, electronics, and software elements of the products. Check out this article about ECM and CM trends written by Jos Voskuil.

These are some interesting facts that you might find relevant for the activity of the company and product development:

- Multiple data representations about the product (mechanical, electronic, software)

- Multiple dimensions of the lifecycle (physical operational vs virtual design)

- Dependencies on software and the way software impacts the product

In my previous article, I gave you an idea of how OpenBOM can be used to connect virtual and physical data sets of the product by connecting bills of materials created and revised during the design phase with data sets representing physical product instances. Check out the following article – Connecting Virtual and Physical Objects in OpenBOM.

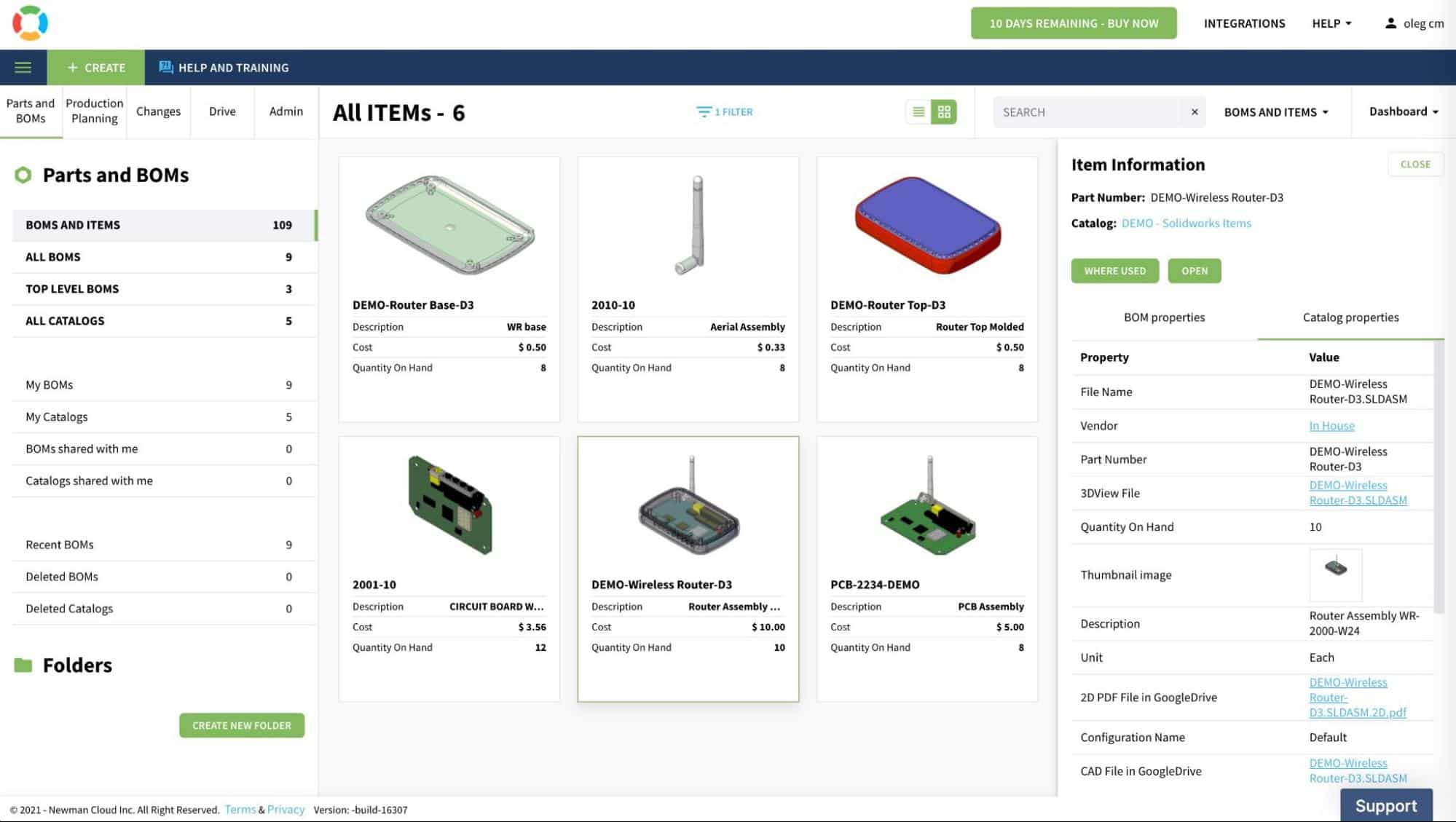

In today’s article, I want to give you recommendations on how you can use OpenBOM to manage complex product definitions including data sets representing mechanical, electronics, software, and other possible data representations.

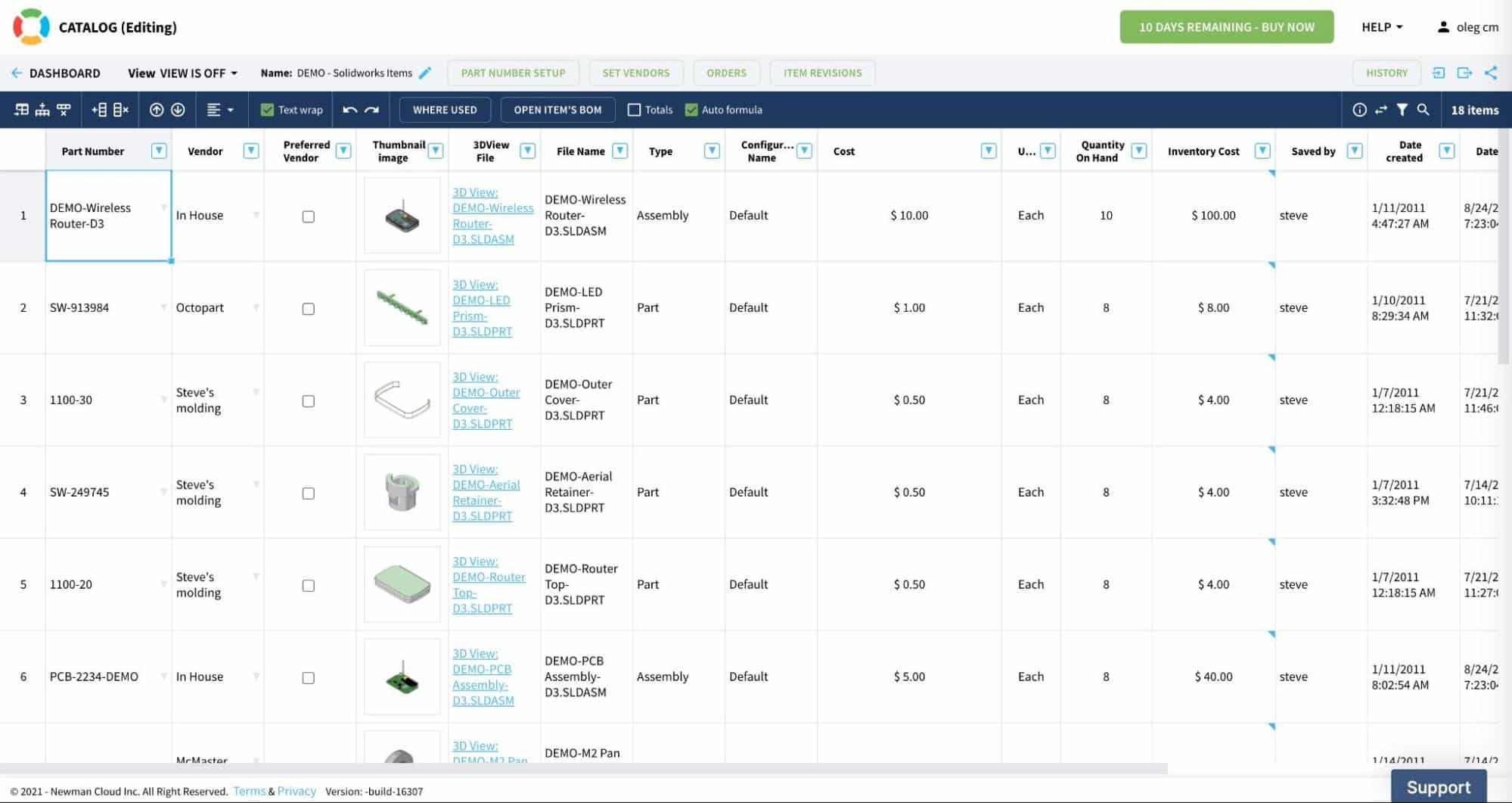

Multiple catalogs

OpeBOM catalogs is a distributed data management system that allows you to organize a flexible classification model of any item type. The model is robust and powerful and allows you to manage different types of data – mechanical, electrical, electronics, software, etc.

A typical organization using OpenBOM can create a couple of dozen catalogs to manage their items with specific data properties, so each item is represented as an individual dataset. Each item has its own historical and immutable set of revisions that can be traced and the history can be retrieved and traced to specific product data representations (BOMs).

Check out more about OpenBOM catalogs in OpenBOM Training Library.

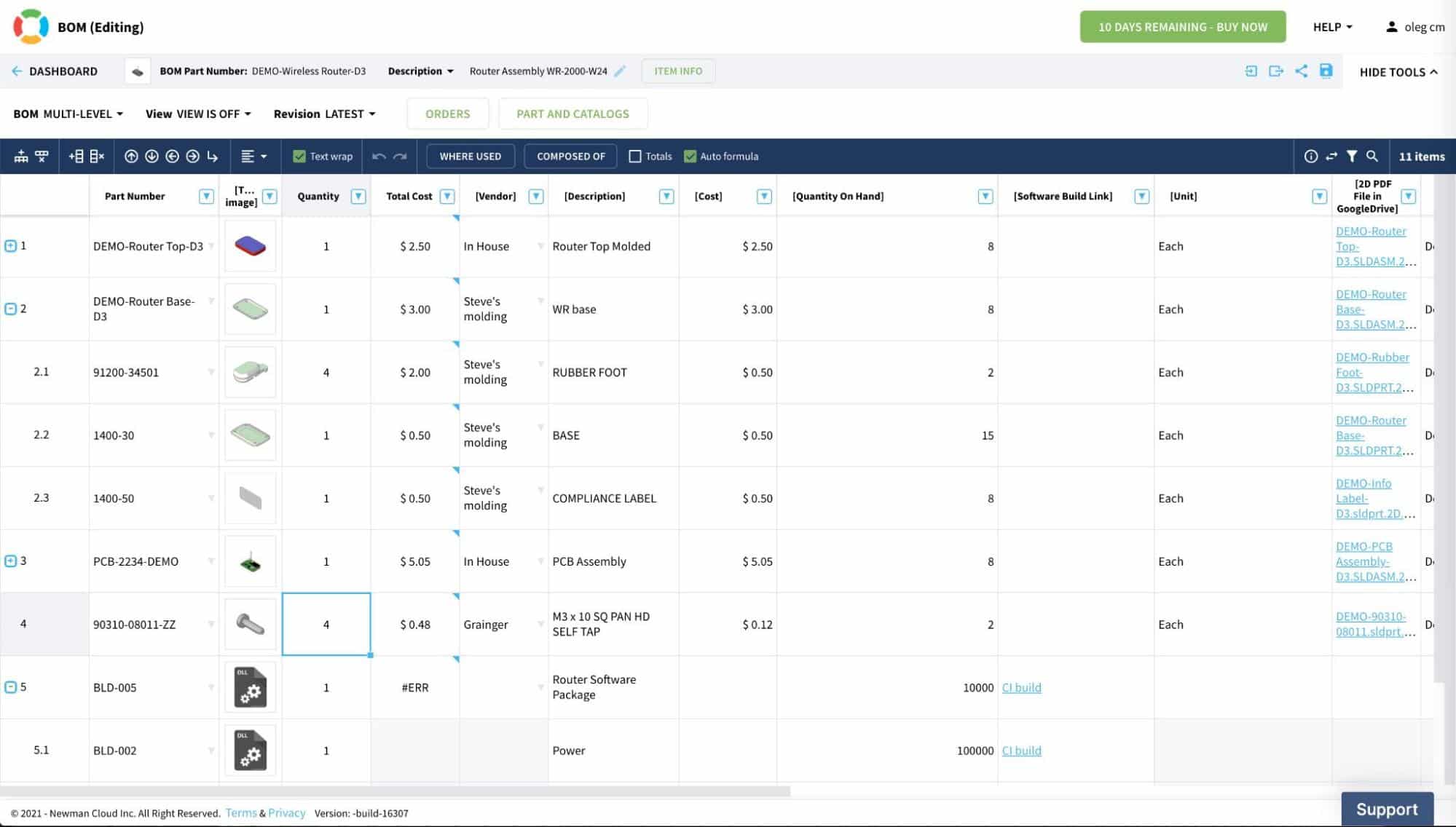

Bill of Materials Granularity

BOM object is a foundation of product structure and allows you to create instances of items from catalogs. A typical BOM is a list of items from one or multiple catalogs accompanied by a set of “instance level” attributes. Typical examples of these attributes are Quantities, Reference Designator, etc. OpenBOM’s flexible data model allows users to add more information including calculated properties. These properties will be also added to a BOM (eg. Calculated Cost, etc.)

OpenBOM automatically builds a structure based on the Part Number relationships between the Part Number of the BOM Item and other items in the BOM. You can build them top-down or bottom-up, eventually, you will have a full structure that is created and can be always extended in all directions.

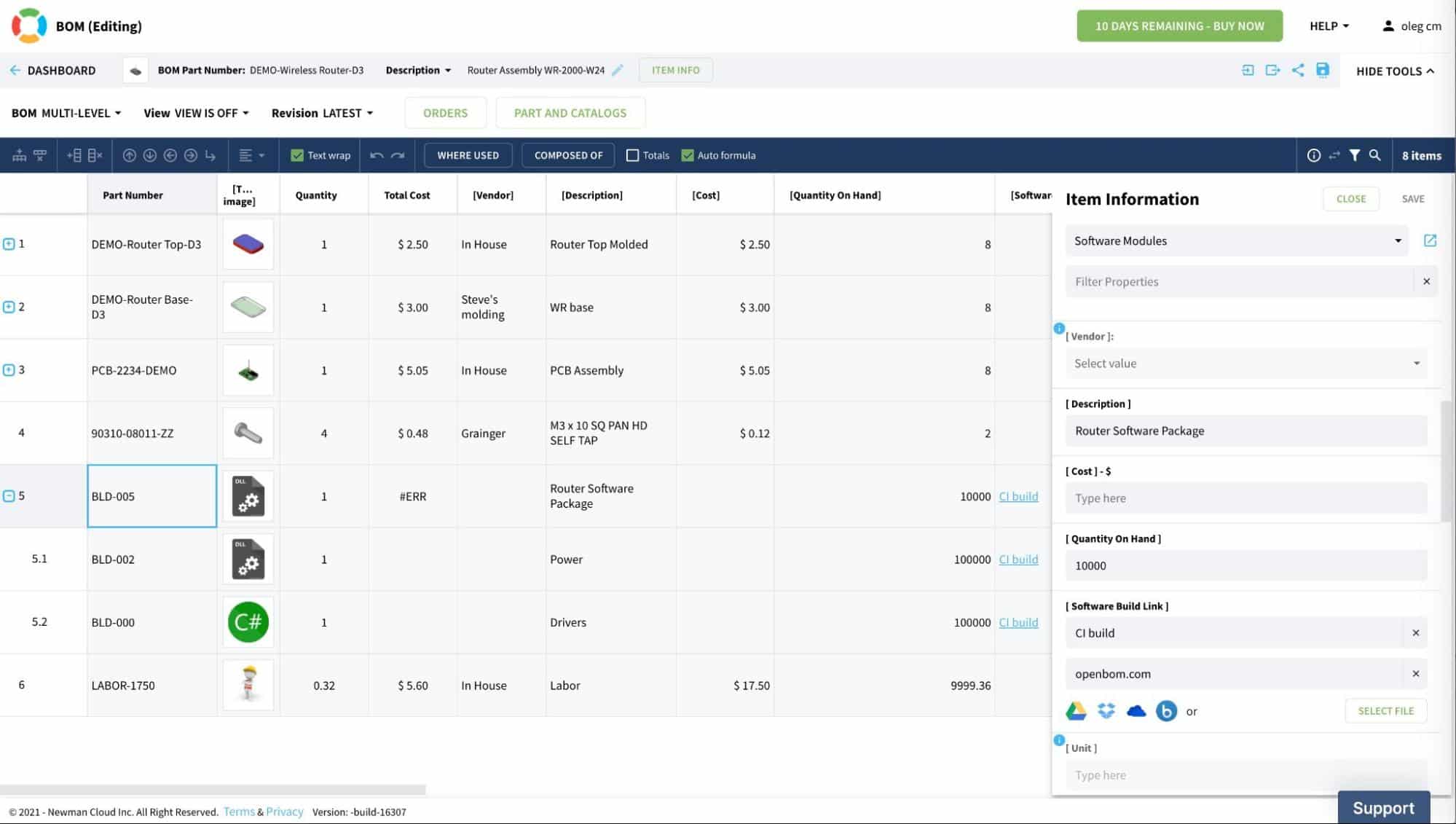

Here is a typical BOM structure in OpenBOM, which includes multiple modules and structures – mechanical, electrical, PCB and software. Each element of this structure can be created automatically from CAD systems, imported from Excel, or created manually.

The structure you can see above is fully traceable related to revisions of items used in this bill of materials.

Connecting Things Together

Change is the only constant thing in product development. Once you get the data organized with multiple catalogs, property settings, and Bill of Materials, the process of changes is kicked off. This is where OpenBOM gives you full traceability on the history of changes, revisions, who did what, and when. All these pieces of information are connected together and can be discovered using history of revisions and where used commands in OpenBOM.

It includes revision history and changes.

Data and revision history navigation can be done from multiple perspectives, so at any moment of time, you will have a full representation of the data and related information if it is a mechanical part, electronic PCB assembly of software build.

Change Management

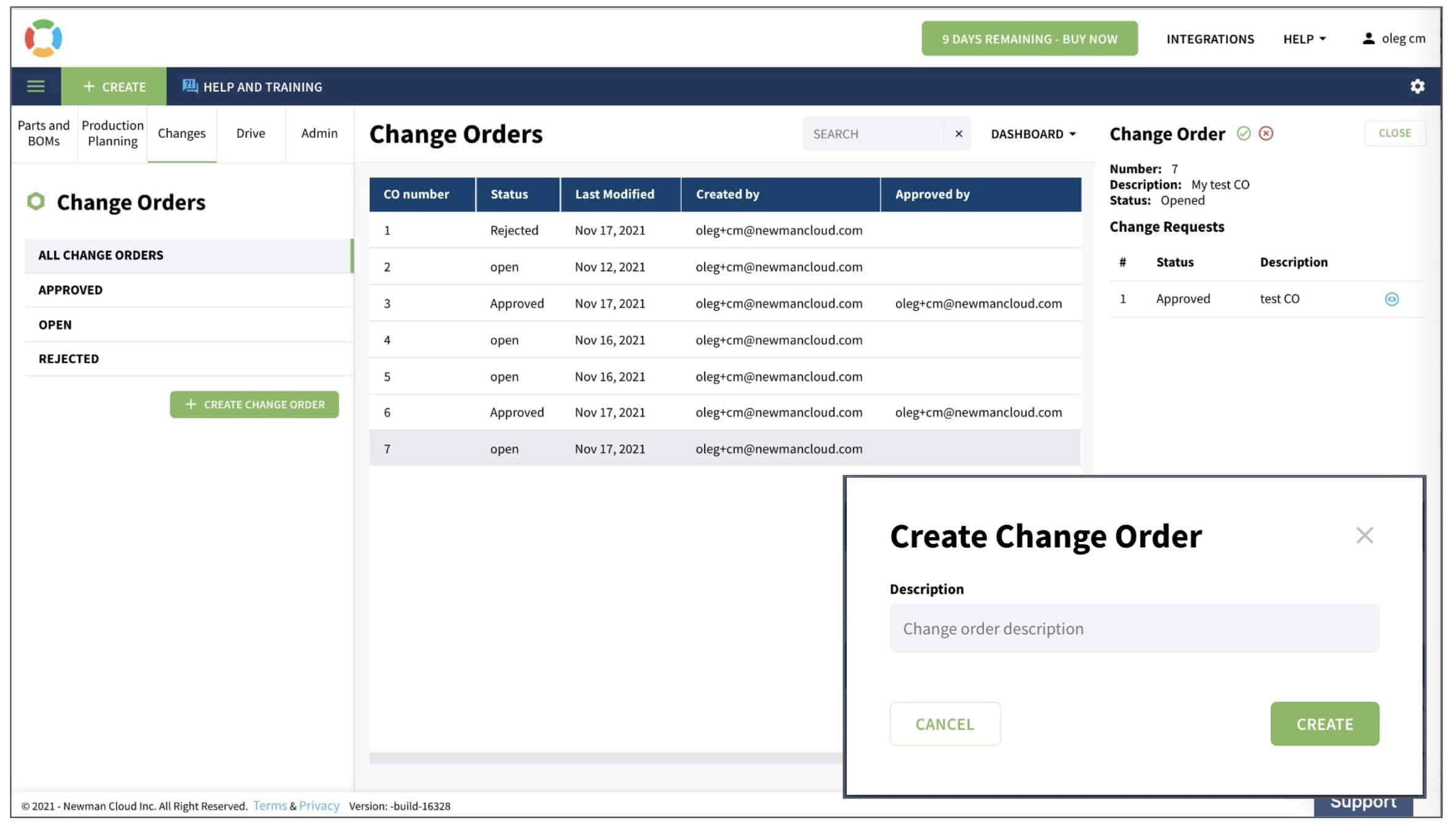

The last element of configuration management is the ability to manage changes in processes and connect specific change requests that are happening in each specific item or module together into a single approval process routed between people. OpenBOM change request and approval module is part of the change management environment. Besides that, OpenBOM is coming with a new Change Order dashboard to provide centralized access to all changes – open, approved, requested, and rejected.

Conclusion

As you can see from this article, OpenBOM gives you a flexible data management platform to manage granular datasets representing multiple pieces of data about the product. As such you can manage mechanical, electronics, and software configuration items independently. You can manage their lifecycle using the revisioning mechanism, to get immutable traceable records of the information and also to have a change management process organized to perform a connected process of controlling changes across multiple data sets.

Are you designing and manufacturing complex products that require multiple disciplines and connecting information about multiple systems in these products? Are you still managing multiple Excels with the data and struggling to connect the data and process together? Reach out to our support and talk to us today (support @ openbom dot com)

REGISTER FOR FREE to learn more about OpenBOM’s capabilities.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.