A few weeks ago, I was discussing an interesting trend – PLM and Data Products. The complexity of product information and connected activities has grown and even smaller companies are overwhelmed with the amount data they need to manage. The situation is getting even more complex for enterprise companies with the amount of legacy data and existing enterprise systems- PLM, ERP, CRM, MES, and others.

At OpenBOM, our vision is to build a modern data foundation to help manufacturing to make better decisions with accurate and connected data. The core of OpenBOM digital thread platform is robust product data model (also called product knowledge graph) that enables organizations to effectively structure and manage a wide range of product information, ensuring seamless product development while also allowing data integration across multiple systems. The ability to connect various elements of product information is crucial, as many organizations manage data across different sources.

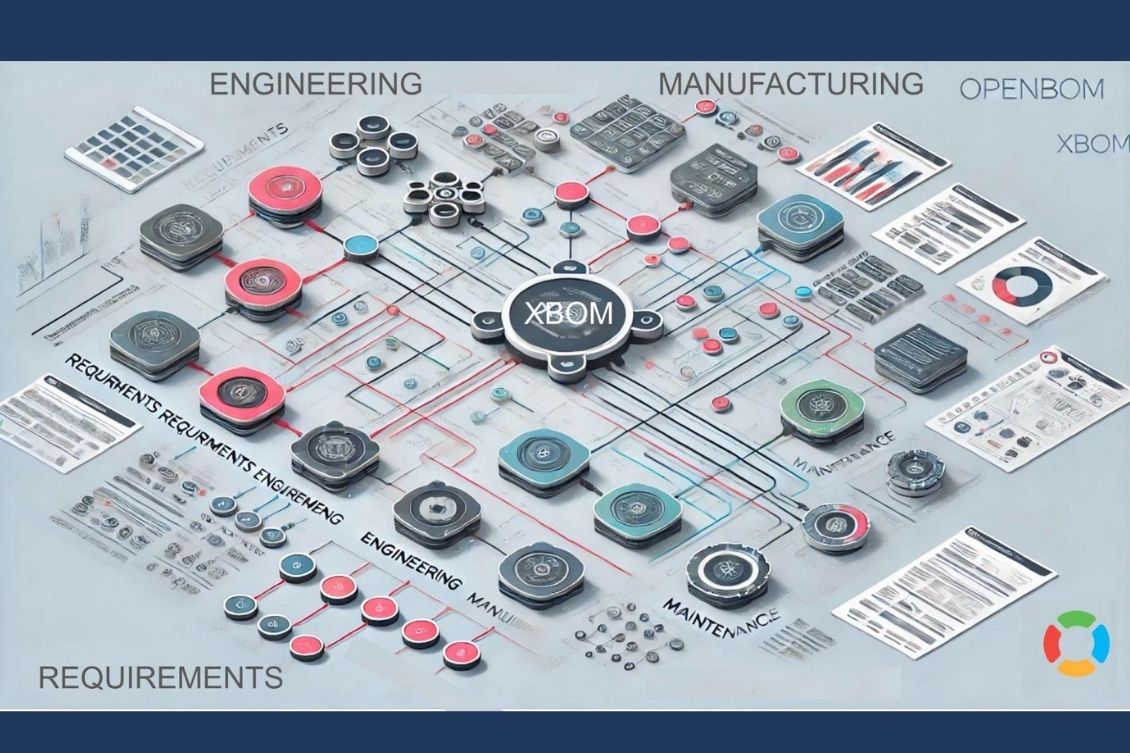

In this article, we start to explore how OpenBOM data platform, allows to build a foundation for a connected digital thread through its structured xBOM framework. We demonstrated how you build a data model with information captured from initial requirements to engineering and service. In the following articles we will show how to connect this product knowledge graph to other systems and turn it into a connected Digital Thread as a Service.

Modeling a Bicycle in OpenBOM

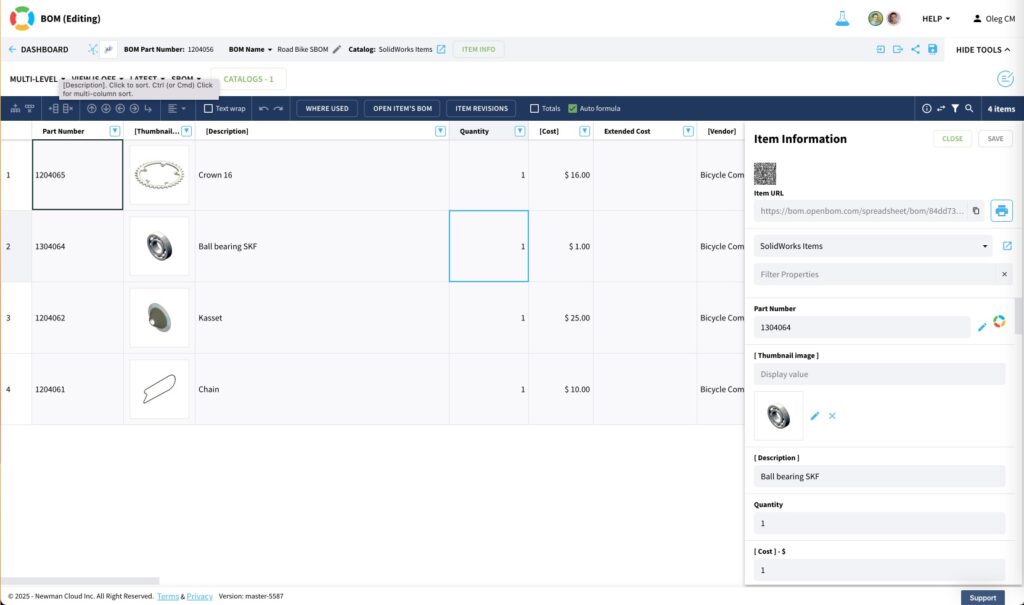

To demonstrate the flexibility of OpenBOM’s xBOM service, let’s take the example of a bicycle. The model begins with defining structured requirements, followed by the engineering BOM, and finally the spare parts and maintenance BOM. The structure we present is entirely flexible, allowing any organization to configure it to fit specific constraints, properties, and information requirements. This customization ensures that each company can manage its product data according to its unique workflow and business needs.

Organizing Product Data with xBOM

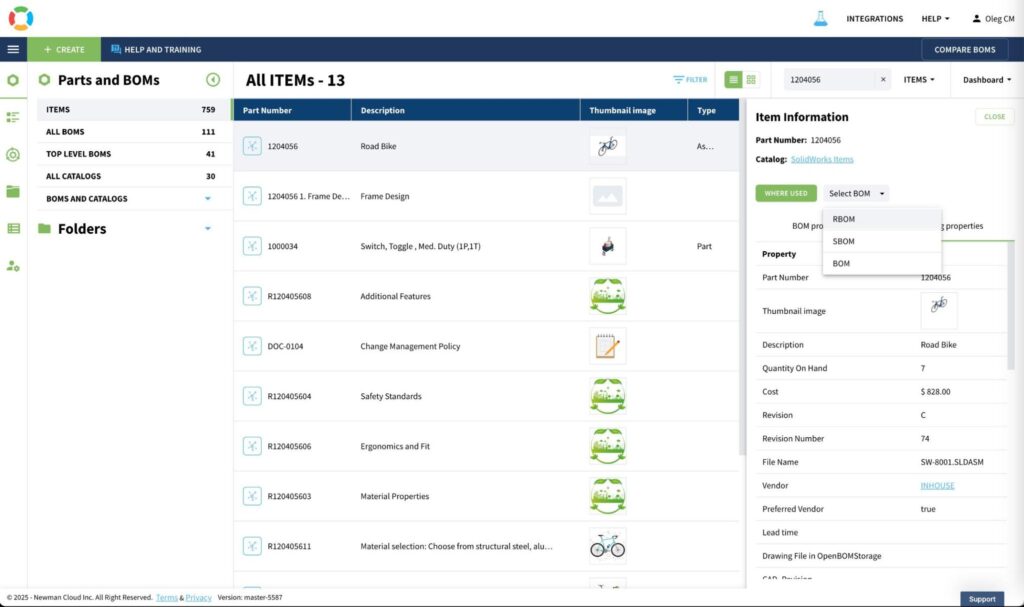

One of the key strengths of OpenBOM is its ability to streamline the organization of product data through efficient navigation. The platform provides a full-text search feature that allows users to quickly locate specific items, whether they are engineering components, product requirements, or maintenance parts. This capability enhances accessibility, making it easier to interact with complex product data structures without unnecessary delays.

Search drive interface gives you a way to access any information.

Requirements, Engineering, and Maintenance BOMs

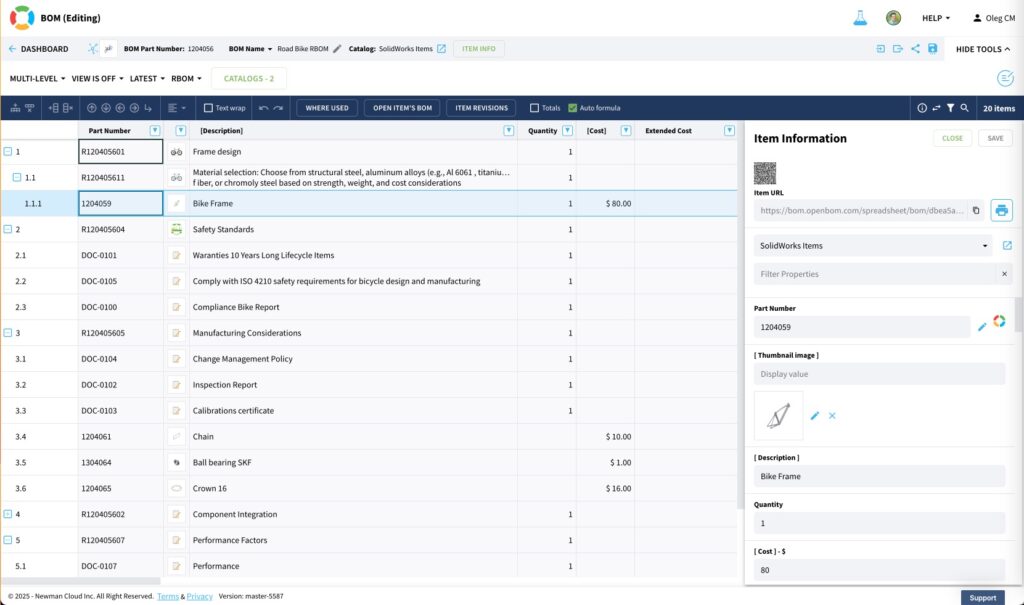

Structured requirements play a crucial role in product development, and OpenBOM supports the creation of a Requirements BOM. This structured approach allows organizations to define requirements systematically and, when necessary, link them to specific physical product elements. By maintaining a clear connection between requirements and actual engineering components, teams can ensure better traceability and compliance throughout the development cycle.

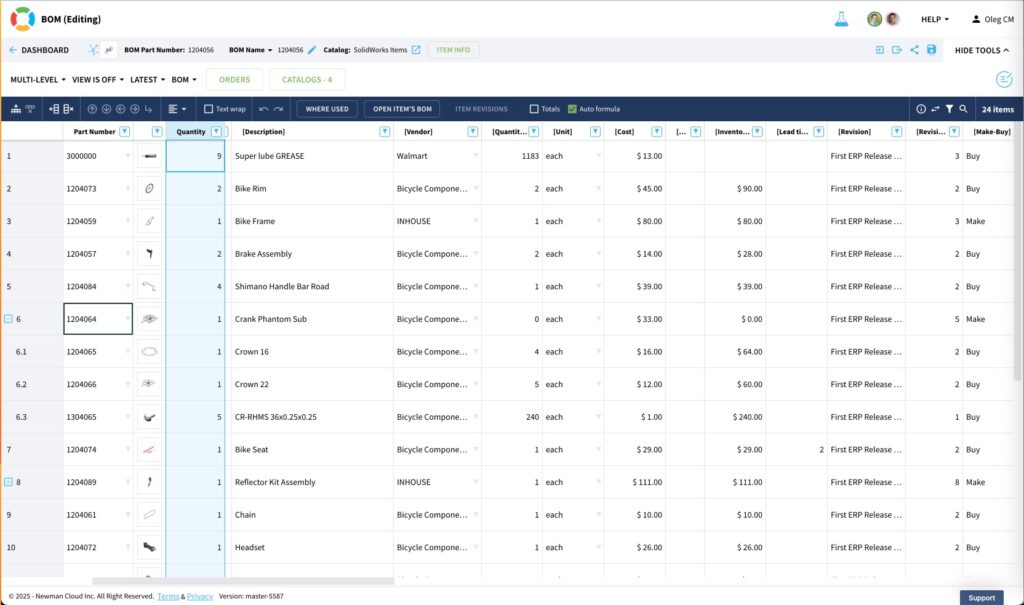

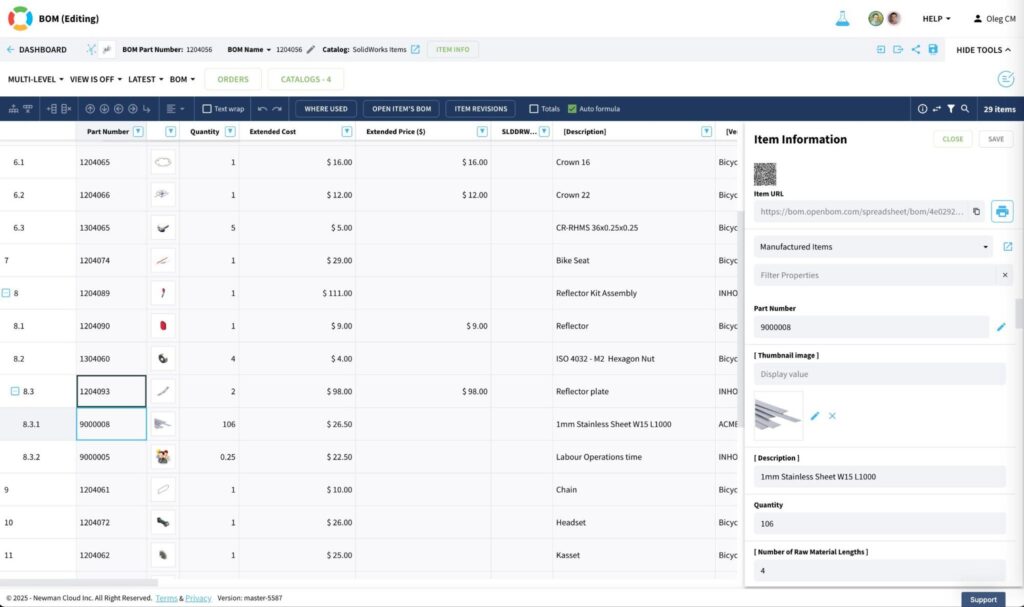

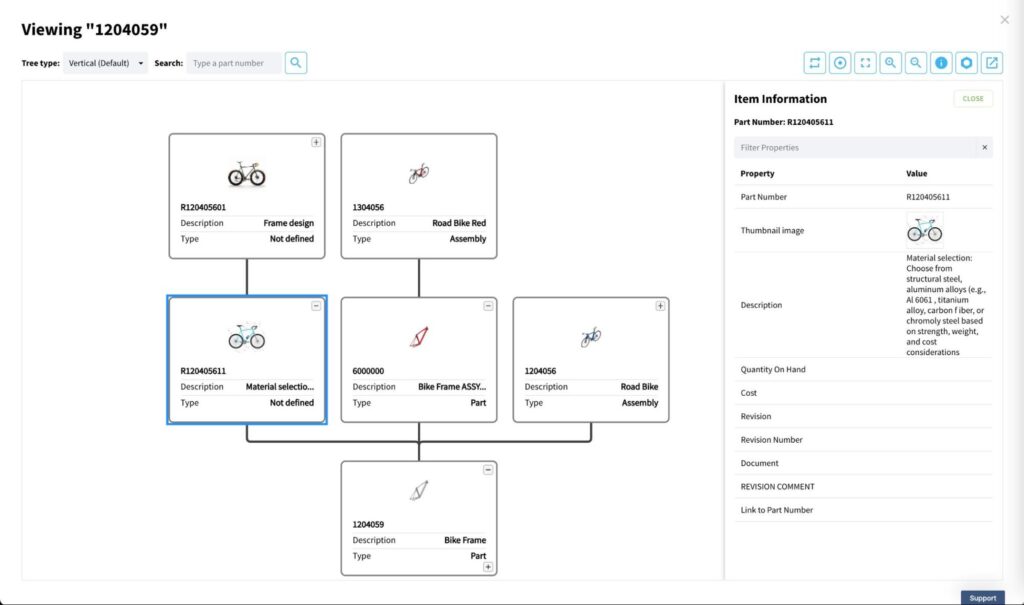

The Engineering BOM, or eBOM, represents the physical structure of the product, capturing the complete design, including all engineering items and assemblies. OpenBOM’s xBOM model offers a fully configurable and customizable approach, allowing teams to adapt their engineering BOM to their specific needs. By integrating engineering components effectively, OpenBOM ensures that teams can manage product definitions with high accuracy and maintain consistency across different product variations.

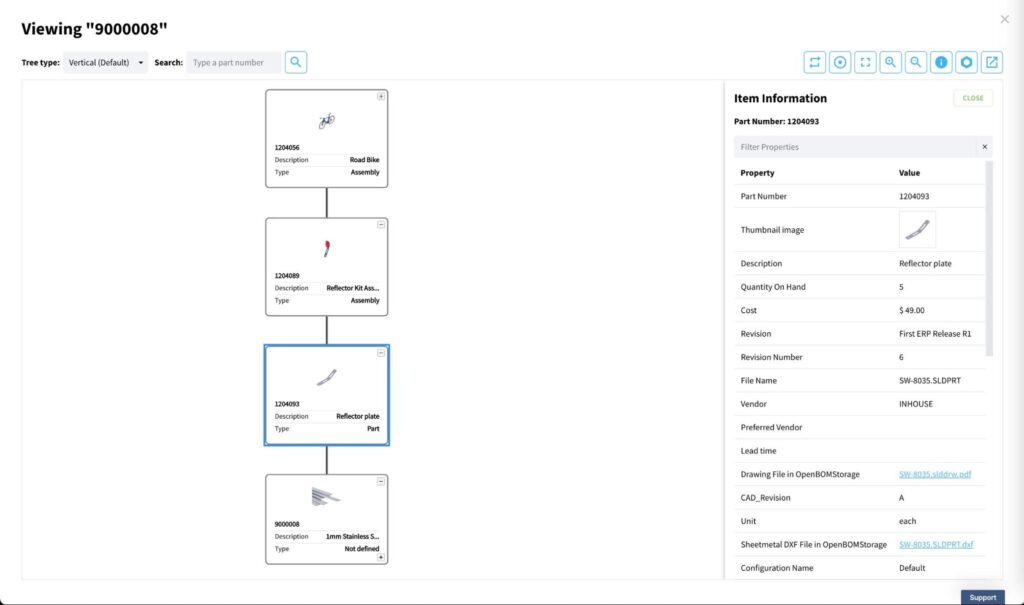

In addition to engineering data, here is an example of the creation of a Maintenance BOM, which encompasses all spare parts required for servicing and sustaining the product throughout its lifecycle. This structured approach helps organizations manage aftermarket support more efficiently, ensuring that spare parts are readily available and properly linked to the relevant product assemblies. By maintaining an up-to-date Maintenance BOM, companies can reduce downtime and improve customer satisfaction.

Advanced Navigation and Impact Analysis

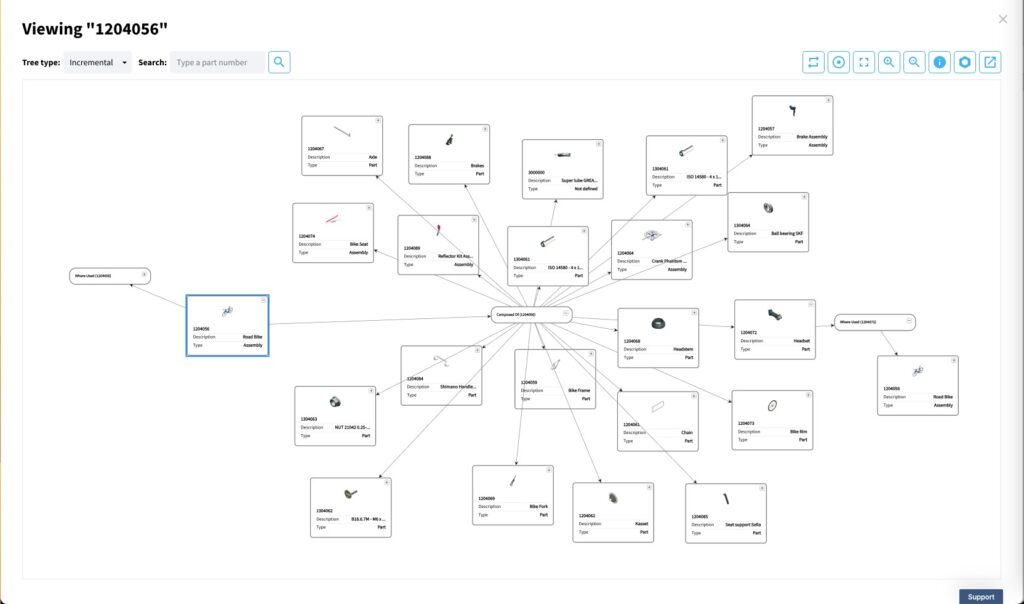

Beyond data organization, OpenBOM provides powerful tools for navigating and analyzing product relationships and dependencies.

The platform’s “Where Used” functionality allows users to track the utilization of specific components across multiple product configurations, ensuring that changes in one area do not lead to unintended consequences elsewhere. This capability is essential for maintaining consistency and preventing costly errors in product management.

Additionally, OpenBOM’s graph navigation feature enables both top-down and bottom-up analysis, offering a visual representation of connections between requirements, design elements, and maintenance components. This approach helps teams identify potential impact points during change management processes and facilitates better decision-making when modifications are required.

Conclusion

OpenBOM’s robust and flexible data model provides a strong foundation for building a Product Data As A Service to support creation of Digital Tread between multiple data sources. The foundation of this service is OpenBOM’s Product Knowledge Graph, integrating all aspects of product development, including requirements, design, engineering, and maintenance. By ensuring seamless connectivity between these elements, OpenBOM enables companies to optimize their product data management processes and drive operational efficiency.

In the upcoming articles, we will dive deeper into each aspect of this structured data model, showcasing real-world examples and providing video demonstrations to help users navigate and analyze data for effective design and impact analysis during the change management process. Stay tuned!

REGISTER FOR FREE to check how OpenBOM can help you. Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.