Companies are always trying to stay ahead of their competitors and bring new products to market faster than ever. One of the keys to achieving this is by forming effective partnerships with experts who can provide the necessary knowledge and resources. One valuable partnership the manufacturer tries to develop is with their contract manufacturer (CM).

As the manufacturer recognizes the benefits of working with a CM, they will have access to their expertise, experience, infrastructure, and more in order to take their product from development to production.

In this blog post, we will explore how your CM can support you during development and how you can take the proper steps to turn them into a partner.

Why is your Contract Manufacturer a Partner?

Trying to align all parties to develop and launch a product is not easy. It’s not just the product team that needs to be aligned, but also, everyone in the manufacturing organization to make sure that when the product is launched that the public is informed and you have buyers standing by.

With limited resources, manufacturers are unable to place the necessary funds in each department in order to optimize their product launch. Sometimes, the product team is underfunded, so they can’t develop the product properly. Or sometimes, the marketing team is underfunded so you can build the product but no one knows about it. Both are common failures.

However, what if you can leverage the expertise of a company that can help bring your product to market? Also, what if that company did not charge? Therefore, you can place those needed dollars to the marketing and sales team to build hype and start gathering pre-orders.

This is the value of partnering with a contract manufacturer.

The clear value of partnering with a CM is that they will help you to go from development to production and they might provide this service for free, assuming they have production rights of the product.

Here are three ways that benefit your company by partnering with a CM during the development

Navigate from Prototype to Production

It takes a different kind of team to take you from idea to prototype and then from prototype to production. The tools, expertise, materials, and methods all change as you transition from prototype to production. What was common in prototypes, such as 3D printing parts will not be feasible in production. Therefore, a transition is necessary to bridge the gap between prototypes and production.

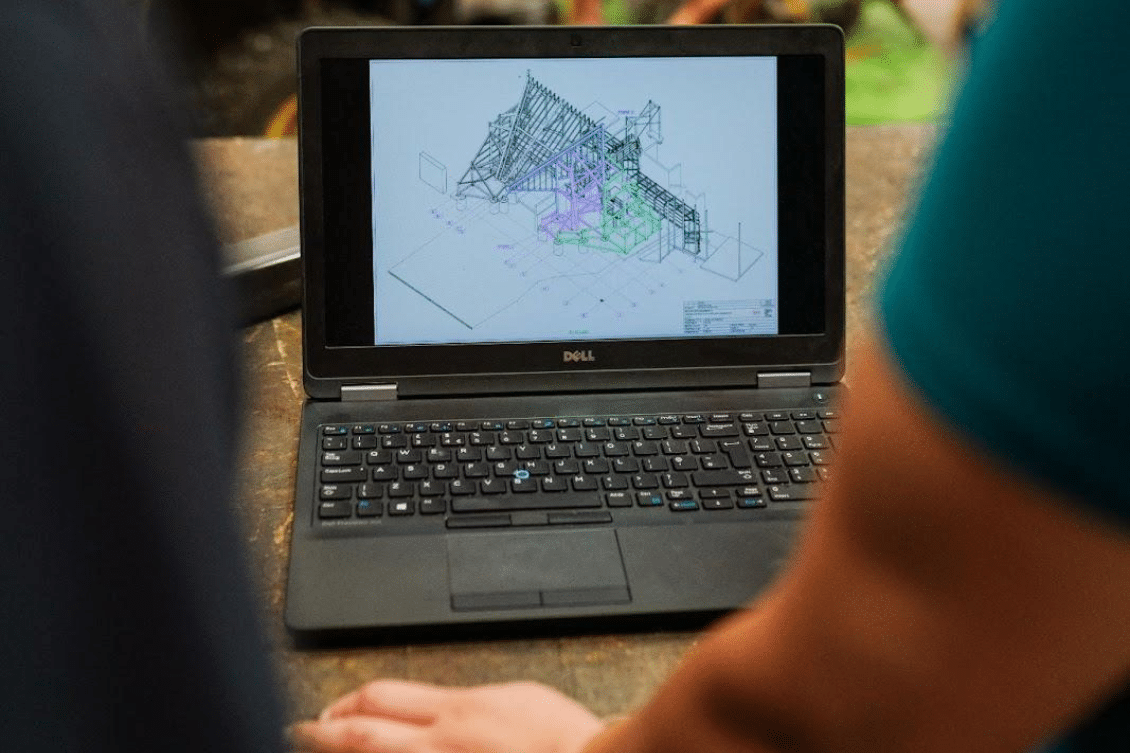

During design for manufacturing (DFM), you and your CM will go through the process of optimizing each part for production. You will look at the fabrication process, materials, quality, and lead time of each part to ensure that all of the parts align well with your product goal.

Here are the main focus points of DFM:

- Part and process optimization for production

- Tool design

- Quality embedded in the design

- Cost analysis

Improve Quality

Quality does not magically appear when a product reaches mass production. It is a fundamental aspect of the product that is determined long before assembly. In simple terms, if the design is flawed then your product will be flawed.

For manufacturers, it can be challenging to design a product without having a clear understanding of the manufacturing processes involved. However, collaborating with a CM who specializes in the specific manufacturing methods, materials, and processes relevant to your product provides a significant advantage. Their expertise allows them to optimize your design for efficient production.

To minimize the risk of defects during the production process, it is important for your CM to provide you with DFM guidance. This ensures that all components are optimized before production begins, reducing the likelihood of manufacturing-related issues.

Lower Costs

In many industries, particularly manufacturing, companies strive for excellent quality but are often hesitant to invest in higher-quality materials and production methods due to the associated costs. However, in manufacturing, what is the relationship between a more expensive product and its quality?

During the product development phase, cost considerations are often not a top priority. The main focus is on ensuring that the product functions correctly, regardless of the expenses involved. However, neglecting to track costs during development can lead to unexpectedly high production costs. This realization may come as a surprise when you start requesting quotes from CMs.

A competent CM will review the Bill of Materials (BOM) and other product data provided during the request for quotation (RFQ) stage and identify any excessively high costs. There can be various reasons for these high costs, including:

- Over-engineering the product

- Using inappropriate materials

- Unnecessarily tight tolerances specified

- Incorrect manufacturing processes

How to Turn Your Contract Manufacturer into a Partner?

Turning your CM into a partner is not a quick task, it takes a change in mindset and also patience. Rushing into this decision will quickly lead to regret. Take the decision seriously and with caution as you proceed with partnering with your CM.

However, if you chose the right CM, you will be able to leverage their expertise and capabilities to improve your product development and production processes.

Here are the four steps to turn your CM into a partner:

Understand your Supplier

While this sounds simple, it’s an important first step. If you don’t understand your supplier and how they work then you won’t be able to work with them.

You need to understand their specialties and capabilities. If a CM is strong with electronics then they probably can’t provide you with the best support on the mechanical side.

If we follow the Toyota and Honda approach, they will only start suppliers after they understand everything about them. Once this is accomplished you can enable collaboration.

Your CM is also looking for this partnership as well for a specific reason, what is that reason? Provide transparency to your supplier about why you would like to partner during the development processes.

Turn Your Supplier into an Opportunity

A lot of manufacturers have the tendency to view their CM as a threat. Perhaps, they have multiple other customers who are similar and manufacturing products within the same industry and they feel they will trade secrets. However, if this is the case and you lack trust in your CM then why are you even considering working with them?

Companies that understand how to bring products to market quickly look at this differently. They identify their CM as not a threat but an opportunity to help them to accomplish their goal which usually is bringing products to market as quickly as possible.

Supervise Your Supplier

Nobody wants to be micro-managed and nor does your CM. It makes them feel you don’t trust them and that’s a feeling no one wants. This is the same as your CM.

Properly supervising your supplier to make sure they are achieving the milestones is important. If they are delayed then your product launch will be delayed so it’s important to properly manage them.

Joint Collaboration

This is the stage where you have all of the foundations in place to expand your relationship. This is where things can get a little bit more exciting.

Once you reach this stage, your CM understands your goals and what is expected from them. They also understand that a partnership with you can be financially rewarding once the product starts shipping.

If you are able to achieve true collaboration with your supplier then you will not just see improvements on the development side but you’ll see it in other areas as well, such as:

- More favorable payment terms

- Cost down projects

- Investments in your company

What can you do Today?

Companies are looking for ways to bring their products to market faster. They implement agile development, leverage partners, and more. While all these methods offer you the opportunity to bring your product to market quicker, you still need the tools to support your mission. Meaning, you can’t continue to use Excel and expect to improve your speed from development to production.

Digital transformation will help you to transform your processes to keep all of your product data together. To have a centralized platform that connects your team with your contractors is extremely important to set up modern digital processes to save time and money.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500s use OpenBOM to create a centralized database to bring in, store, and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or collaborate with contractors and suppliers. Contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.