In the realm of product lifecycle management (PLM), having a flexible and robust data model is paramount. This model serves as the backbone for managing the complexities involved in designing, manufacturing, and maintaining products. Among the myriad of tools available for PLM, OpenBOM stands out by offering a flexible reference-instance data model, enabling users to create granular data representations for both catalog items and Bill of Materials (BOM) instances. Let’s delve deeper into the significance of this approach and how OpenBOM simplifies the user experience.

Why Data Model Flexibility Is Important?

Flexibility in data modeling is crucial for accommodating the diverse needs of product development and management throughout its lifecycle. OpenBOM’s approach allows users to define items within catalogs (reference) and instantiate them into BOMs (instances), offering a seamless and intuitive user experience. This flexibility ensures that users can accurately represent components from catalogs and their instances within BOMs, facilitating effective collaboration and decision-making.

OpenBOM Data Model

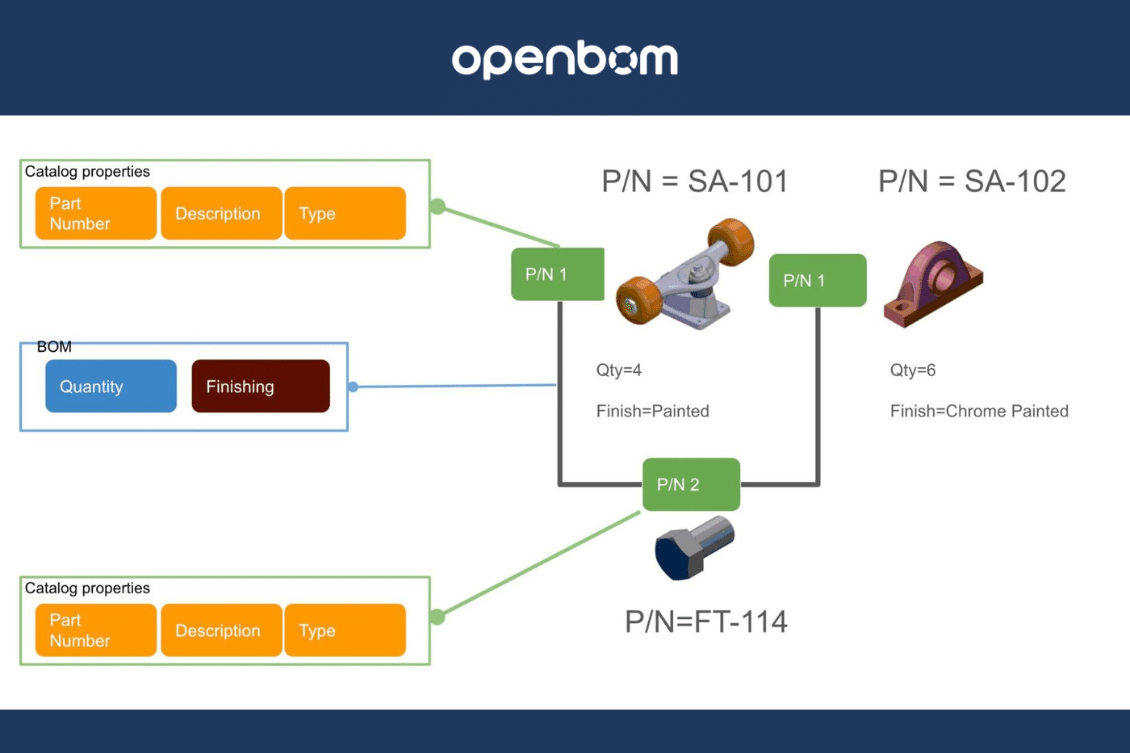

The OpenBOM data model provides a comprehensive framework for defining both catalog items and BOM instances. In this model, items are categorized into different catalogs (Item types), and users can instantiate these items into BOMs, customizing properties for each instance. For instance, a screw can be instantiated with different finishes and utilized across various assemblies, maintaining consistency while accommodating specific requirements.

In the following picture, I will show you a specific example of the model where a single bolt can be modeled with different “finish” properties in different BOMs.

Demonstrating OpenBOM Functionality

In the following videos, we’ll demonstrate how users can define item and instance properties within OpenBOM, edit them seamlessly while saving BOMs from Solidworks, and automate data extraction from Solidworks into OpenBOM. These features empower users to streamline their workflows and ensure data integrity across platforms.

Video 1: This video shows how to create a BOM template with instance properties and use this template when generating a BOM from Solidworks. In this case, you will need to store an instance property manually.

Video 2: This video shows how to use the template (from the previous video) and map an instance property directly from Solidworks.

How To Decide Between Instance (BOM) and Item (Catalog) Properties

A fundamental question arises: when should instance properties be used, and when are catalog properties more appropriate? The answer lies in the understanding of the product model.

As a general rule:

Catalog properties are suitable when uniformity across all instances of an item in all BOMs is desired.

Instance properties are preferred when varying property values are required across different BOMs.

Conclusion

OpenBOM offers a robust, powerful, and, at the same time, a very simple data model for managing product information throughout its lifecycle. Seamlessly integrated with CAD tools like Solidworks, OpenBOM provides users with a robust platform for manipulating data flow and facilitating collaboration.

Experience the capabilities of OpenBOM firsthand by creating a free account and starting a 14-day trial. Discover how OpenBOM can revolutionize your product lifecycle management processes.

REGISTER FOR FREE and check how OpenBOM can help you.

Best regards,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.