Welcome to another article about revision and change management in OpenBOM. Earlier I shared articles with information about revision control and change management in OpenBOM. Here are a few links to check them out:

- Demo Change Management: Overview

- Demo Change Management: Revisions

- Demo Change Management: Change Order and Change Request

- Demo Collaborative Change Approval

The topic for discussion today is Item and BOM revisions. In the complex landscape of product development and manufacturing, it is not uncommon for users to be confused about the differences between parts (Items) and Bills of Materials (BOMs). This confusion often leads to a misunderstanding of the change processes and best practices for revision and change management.

Both Items and BOM definitions play a crucial role in the design and production process. Therefore understanding how to manage them and what typical rules you should follow to avoid potential complexity surrounding items and BOMs is important.

OpenBOM is an online platform that helps engineering teams and manufacturing companies to manage product information and provide solutions for lifecycle management, BOM control, and procurement. The core element of OpenBOM is a product model that allows the creation of product data representing a specific product or system. In today’s blog, I will speak about what is an item, item revision, BOM, and BOM revision to eliminate the misunderstanding once and for all.

Item and BOM

The two most fundamental elements of the OpenBOM core product data model are Item and BOM. You can check the OpenBOM data management course to learn more in depth about the topic. Here is a simple description that can give you a basic understanding.

By Item, OpenBOM understands anything – standard OTS component, manufactured part, purchased assembly, any sub-assembly, or an entire product. This basically means that everything that touches the design, or will be purchased, assembled, and included in the product is considered an Item. The most important element of the item is the Part Number, which OpenBOM uses to uniquely identify it.

A BOM in OpenBOM is a list of components that must be included to build it. A bill of materials (BOM) is characteristic of an item. In such a way, BOM represents a list of items included in an assembly item and it is characteristic of an item.

To sum up,

- Everything is an item in the OpenBOM product model

- An item can be a simple item (eg. part, material, standard component) or an Assembly

- If an Item is an Assembly, it has a BOM (list of items)

- If an Item of the assembly is an assembly, it has its BOM

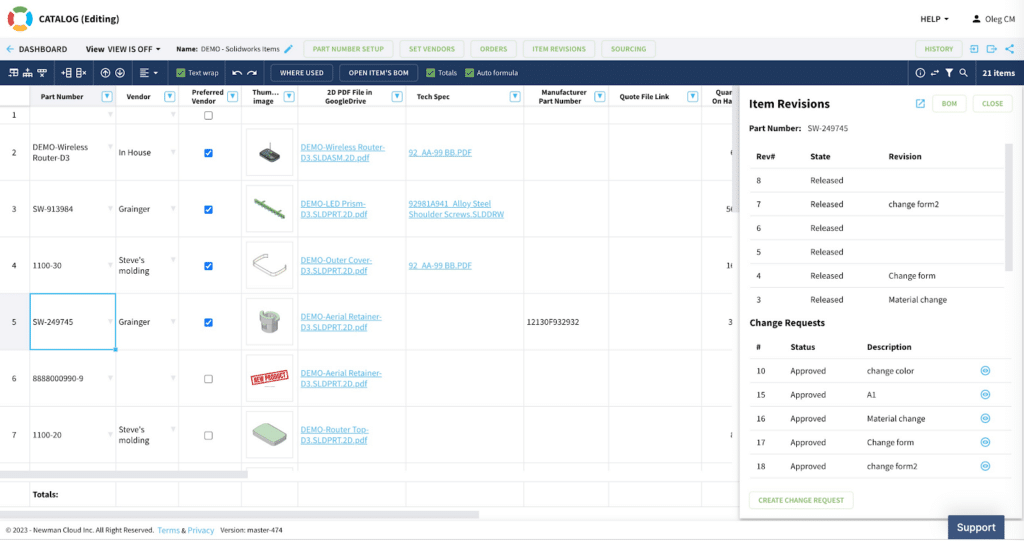

Item Revision

Revisions are a crucial aspect of any product lifecycle. They represent the changes made to a product over time, allowing users to track modifications and maintain a historical record. OpenBOM Revisions can be related to a single part, an assembly, or an entire product. Typical reasons for creating a revision include design changes, part replacements, or modifications to manufacturing processes.

You create Item Revision from the Revision panel:

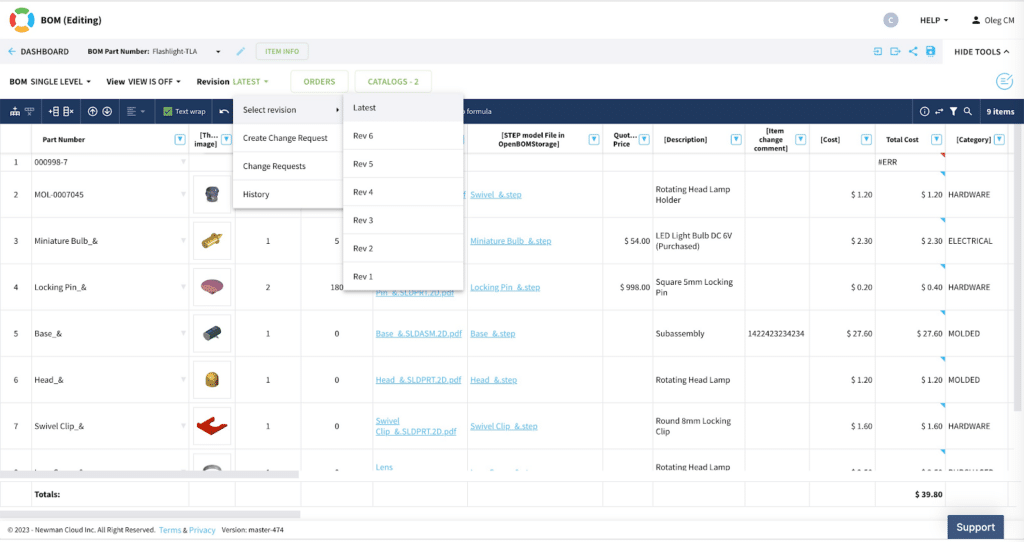

BOM Revision

When you revise an item, which is assembly (BOM), you will be automatically creating a revision of the BOM, because BOM is an associated object with an item. In such a way, you will see BOM revisions in the list in the BOM user interface. What is important is that there is no difference between Item and BOM revisions- they are in fact the same.

You create BOM revisions either from the Item revision panel or from the BOM revision user interface. Please keep in mind those revision commands in BOM and Item are the same. So, no matter how you create a revision from BOM or Item user interface, you will get both item and BOM revisions created.

Can I make only BOM Revision?

One of the questions that come often – should I create only BOM revision (not revising an item). The short answer is NO. Actually, you should always have Item and BOM defined together. Although OpenBOM (still) allows you to create a BOM without an Item, we consider it as a wrong business practice.

Conclusion

Item/BOM revisions are a fundamental aspect of product lifecycle management. OpenBOM makes it easy to create, manage, and track Items and BOM revisions, enhancing collaboration, and traceability. By understanding the importance of revisions and utilizing the powerful features offered by OpenBOM, engineering teams can efficiently manage their product development processes and deliver high-quality products to market.

REGISTER FOR FREE to learn more about OpenBOM.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.