I continue my set of articles about OpenBOM Bill of Materials and Catalogs. If you missed Part One, please navigate here to catch up.

The way to think about Catalog(s) in OpenBOM is to think about an entire set of everything your company manufacturing and all assemblies, sub-assemblies, fabricated components, standard parts you’re using. In a traditional manufacturing resource planning (MRP) and later ERP, there is a definition of an Item (or Material Master). This is what OpenBOM catalog (s) does.

So, think about Catalog as a place where you define all items (parts). The type of item can be different. It can be an assembly, outsourced sub-assembly (eg. sub-system, big unit, etc.), purchased assembly (eg. electrical motor), in house fabricated parts (eg. sheet metal) or standard parts (eg. screw, nut, etc.).

Catalog(s) helps you to define all these items and add any properties that will hold information about items (eg. Cost, Manufacturer Name, Description, Cost, etc.).

Below is an example of a catalog in OpenBOM containing information about parts used for a specific product.

This is only one example and your catalog(s) can look completely different. You can organize data in multiple catalogs or you can bring all items (parts) to a single catalog. Each record in the catalog is a unique part used in many products.

Now, let me move forward and introduce you to a concept of BOM (Bill of Materials) in OpenBOM. Any bill of materials is a list of parts with part numbers. The information about the part is stored in a catalog. The information about “usage” or instance of the part is used in BOM.

Here is a typical BOM created in OpenBOM using the cattalog. As you can see BOM is using the information defined in a catalog.

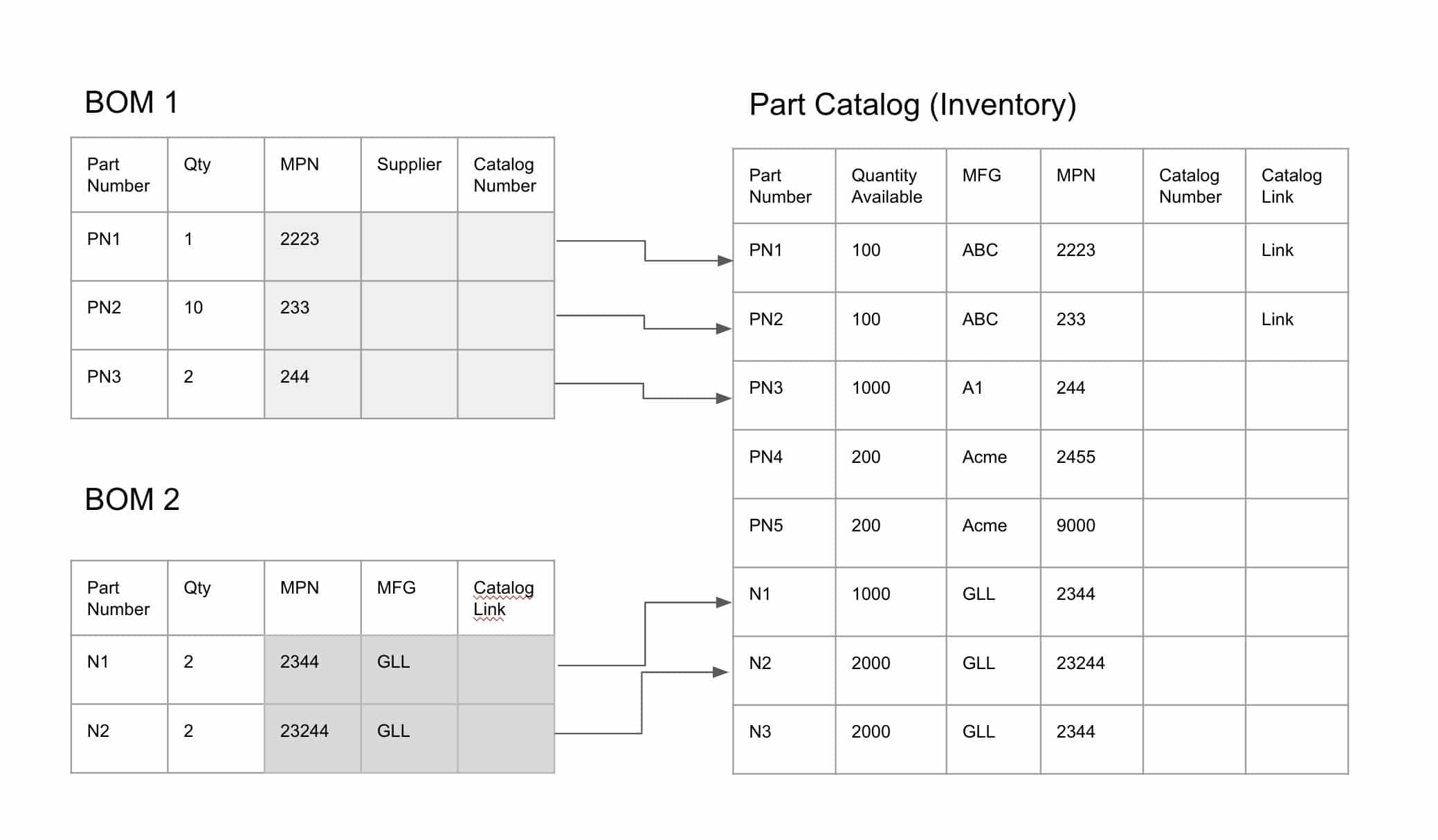

The separation of data between catalogs and BOMs are essential. It allows you to reuse catalog data in multiple BOM and prevents the redundancy in data management applications. The following diagram is summarizing the relationships between BOMs and Catalogs.

Conclusion.

OpenBOM catalogs and BOM are two inseparable elements of OpenBOM data model. Catalog defines references and BOM defines instances. In other words, the catalog says – “I have a screw from A manufacturer, which cost 2$”. Bill of Materials says- I have 2 units of this screw used for a specific product BOM.

I hope your understanding of OpenBOM Bill of Materials and Catalogs is improving. In the next chapter, I will go with some examples of how to create catalogs and BOMs using OpenBOM.

Stay tuned.

Best, Oleg

PS. Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.