One of the questions that often causes confusion in product development and manufacturing is change management. This topic has many ‘names’ – versions, revisions, changes. Those terms are often used in an interchangeable form and, let’s be honest, not always clear. At the same time, managing changes effectively is crucial. Change management involves handling alterations to products, documents, and processes. Although these terms are often used interchangeably, they have distinct meanings and applications. This article aims to demystify these concepts and provide guidance on their appropriate use.

Documents vs Data Changes

A traditional approach in engineering data management is to control documents. For the last few decades, folders and files represented a typical way to manage information. CAD systems save data in files. Specs and other information are managed in spreadsheets. All the tools engineers used in the past 30 years were storing files this way or another.

Therefore a typical question of every engineer in the product development process about the change is “How to revise the document”. And, from a technical perspective, it makes sense. However, when you think about it a bit more, you will realize that things are not that simple. Imagine a mechanical engineer, an electronic engineer, and a software team working on a product. Each of them is making changes. How will you figure out what changes in each of these documents (MCAD, ECAD, Software tools) are the correct modification of a product?

So, things are going to change. We are moving from the age of documents to the age of data. This change will help everyone to manage information (not files) that will help to identify what is the right mechanical design, PCB board, and software that needs to be placed in a version control software and product lifecycle management tools to get what we need. A PLM system with the ability to manage granular data changes, and provide collaborative support for multiple teams combined with a distributed version control system available everywhere will be solving a problem for modern product development teams.

Let’s start with some basics and explain how OpenBOM is managing information to provide support for change management and change control.

Versions: Iteration and Progress

In OpenBOM a version represents a specific state of a document, file, or product at a particular point in time. A typical thing for that is a version of a file in Design Projects. Versions are used to track the evolution of an item as it undergoes development and refinement.

The use case of versions is product development or as we call it “work-in-progress”. The system can use versions internally (Design Projects) or can reference other systems used for version control such as cloud CAD systems (eg. Onshape, Altium 365, or Autodesk Fusion) or software version control (eg. Git). Versions are ideal for tracking incremental changes and improvements during the development process. Each save or commit or update is tagged with a version number, allowing teams to track progress and collaborate efficiently.

In software development, versioning might follow a pattern like 1.0, 1.1, 2.0, etc. In product design, a prototype might go through several versions (v1, v2, v3) before finalization. OpenBOM gives you the flexibility to put any tags on versions.

Revisions and Baselines

A revision indicates a modification or correction to a specific version of a document or product. Revisions are often used to address the progress and identify a specific milestone. They can identify a progress (prototype p1, p2, p3) or fix errors, include customer feedback. A revision usually represents a baseline that can be identified and allows an entire product to be assembled together. It usually refers to a specific version that outcome multiple disciplines (MCAD, ECAD, etc.).

In product development, revisions are essential and OpenBOM uses them to identify a specific item state that can be used for assembly, downstream, or shipment. Every Item in OpenBOM can be revised and if it has a BOM associated with this item, the BOM will be revised as well. This is how you can go back and see a specific revision of an item together with all associated information.

Change Orders: Getting Changes under Control

A change order (also known as an engineering change order or ECO) is a formal process to make changes to a product or process. Change orders typically involve substantial modifications that impact cost, schedule, or functionality. While revisions can be used by every person who has the ability to edit data about the product, change order is a mechanism that requires multiple people to agree on the creation of the change. The outcome of the change is a “revision”, but the process is different.

In OpenBOM, change orders are created using templates. Each template includes a set of attributes (fully customizable) that can help you to collect information about the change. Think about them as a change order spreadsheet you most probably have in your company already. Creating this template for each type of change (engineering, manufacturing, etc.) will allow you to create different mechanisms of data collection and approvals. Before the revision is created, OpenBOM creates a change request for each item in the catalog to track the change.

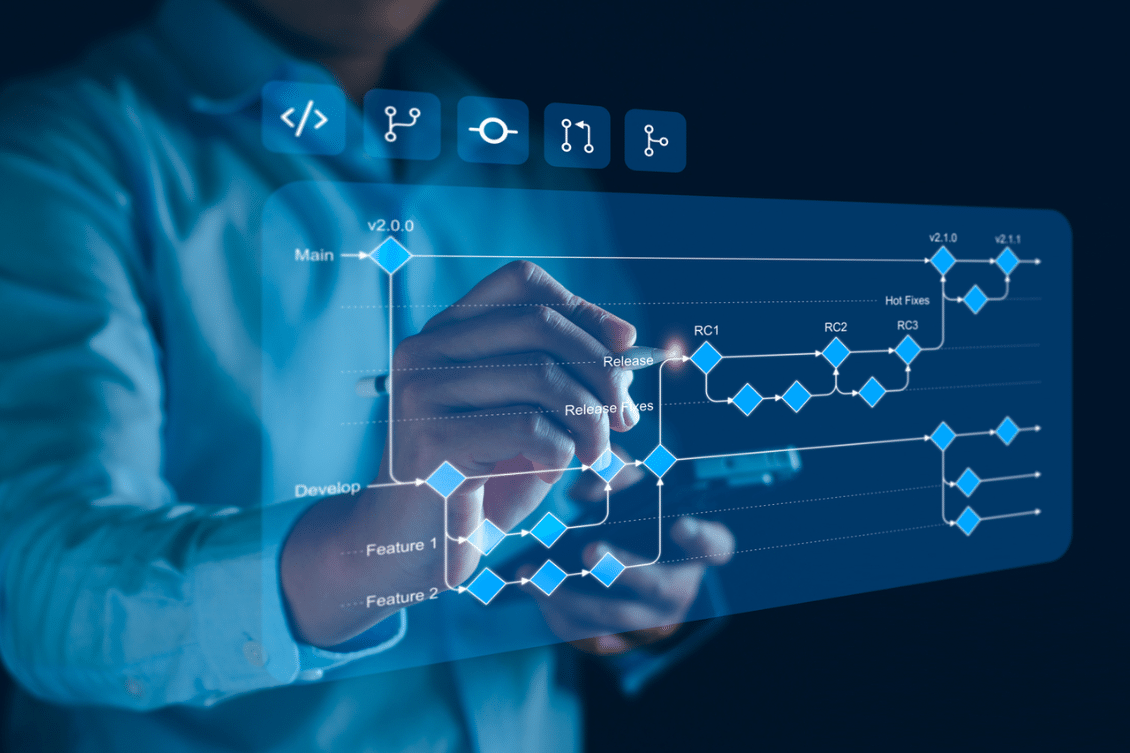

A Big Picture: Versions, Revisions, and Change Order

Combining everything I said, before, here is a big picture of how all these things are lining together- versions, revisions, change requests, and change orders. The picture below gives you a broad perspective on how OpenBOM change management works. You can read more about it in our documentation.

The lowest band is design versions. You manage it using Design Projects or via integrations with cloud CAD and software version management systems. Those systems will give you a reference to a specific part, assembly, or component version.

The work-in-progress band in OpenBOM (so called “Latest State”) represents a workspace where everyone can collaborate together. This is a place where multiple users or teams can contribute and bring all the information and files together. OpenBOM’s unique instant collaborative environment allows you to share data seamlessly between multiple teams and companies to work together.

Revisions, Change Requests, and Change Orders is a mechanism to capture a baseline snapshot using informal (save revision) or formal (change order approval) mechanism.

Conclusion

Effective change management is essential for ensuring the quality, reliability, and success of products and processes. By understanding and correctly applying versions, revisions, and change orders, teams can streamline their workflows, enhance collaboration, and mitigate risks. Clear and consistent use of these concepts helps maintain order and clarity in the complex landscape of engineering and product development.

At OpenBOM we provide a simple and reliable mechanism to manage all these elements of the change process together to help your team and organizations stay on top of all changes and to get the right revision, file, or data in front of your team at the right time.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.