The time when manufacturing companies were practicing “over the wall” manufacturing processes is gone forever. Modern manufacturing companies are looking at ways to establish a continuous connected process that can streamline data integration from initial CAD design downstream to manufacturing, production planning, and procurement.

Information flow and connected services

From a practical perspective, it means automating the process of engineering BOM creation (from CAD system) and also the process of engineering BOM to ERP/MRP by integrating OpenBOM with ERP tools.

SaaS and cloud technologies open a new era in the way data and information flow can be integrated. Using modern REST APIs and seamlessly integrating data connectivity, you can achieve integrating of CAD design with BOM, create a combined multi-disciplinary product structure from multiple CAD systems, add all non-model data element and synchronize it with ERP / MRP functionality.

OpenBOM gives a set of unique out-of-the-box solutions to make the process easy and flexible. For CAD integrations, check out our OpenBOM Integration page. It will give you a list of all mainstream popular CAD add-ins with one-click BOM import included in the OpenBOM subscription as well as many other systems that can be integrated with OpenBOM based on customer requirements.

In my article today, I want to review the process of OpenBOM to ERP integration using popular Oracle NetSuite and OpenBOM Build for NetSuite solution.

OpenBOM to NetSuite Data Flow

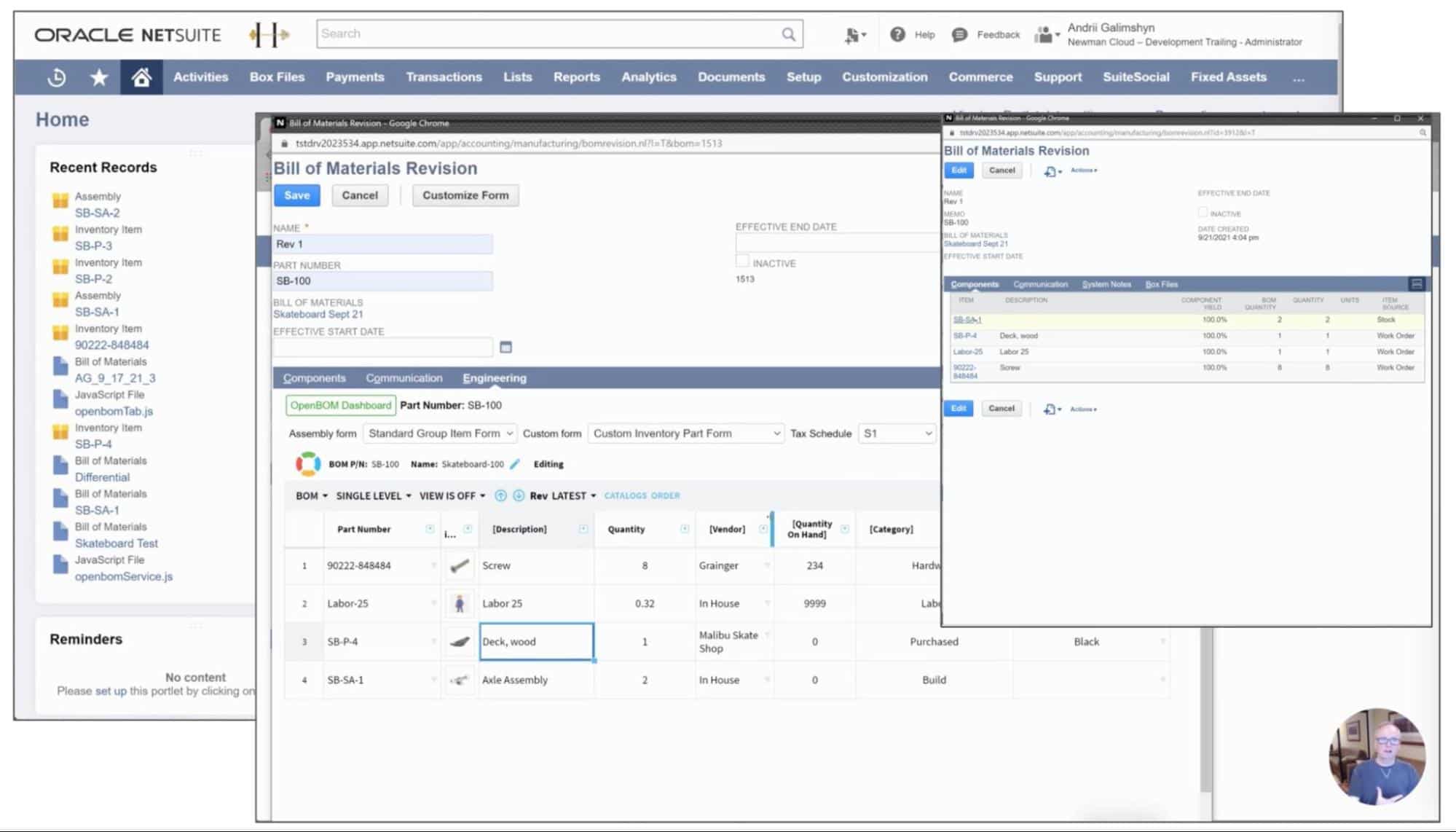

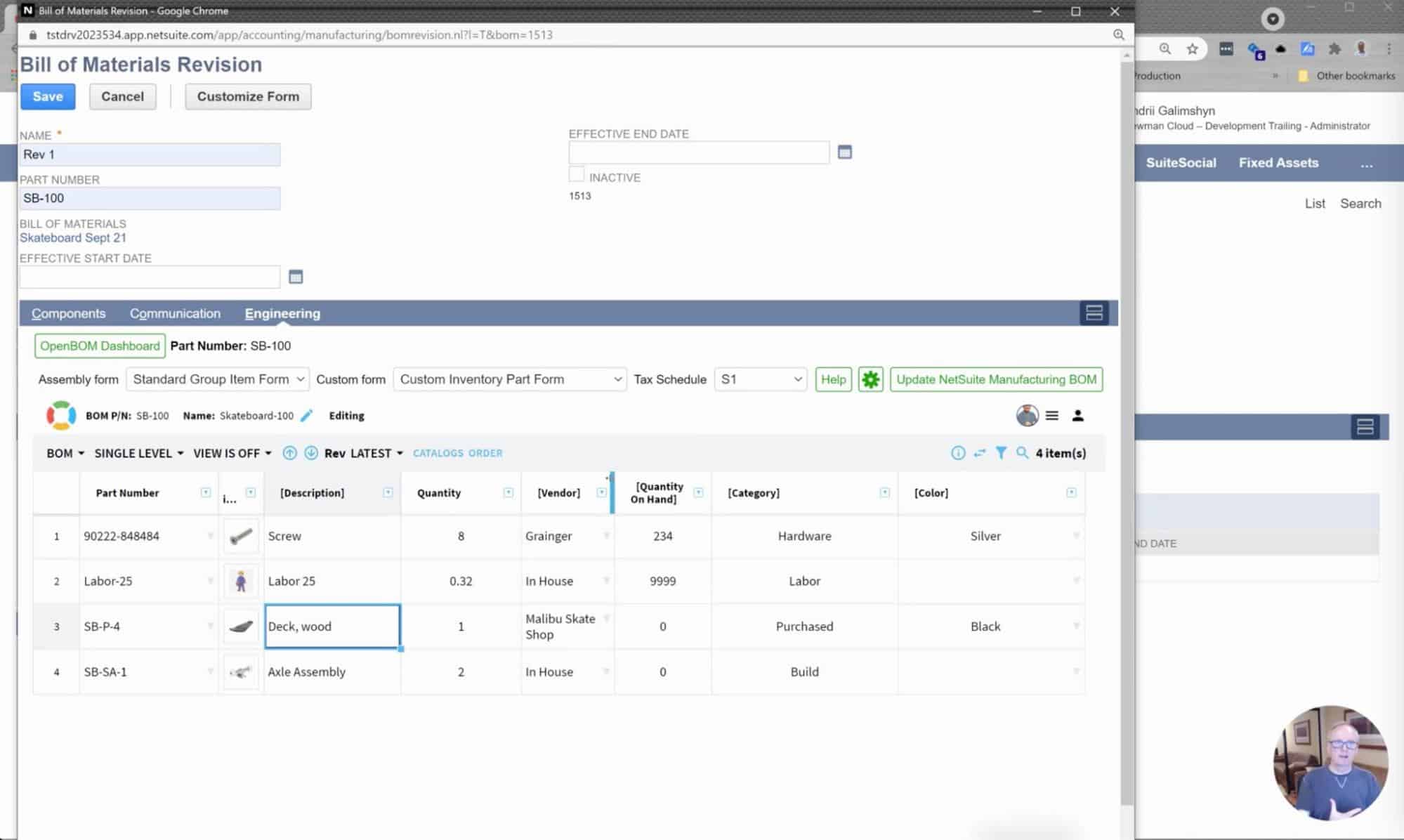

OpenBOM gives you a fully integrated user experience to access the data you created in OpenBOM directly from NetSuite.

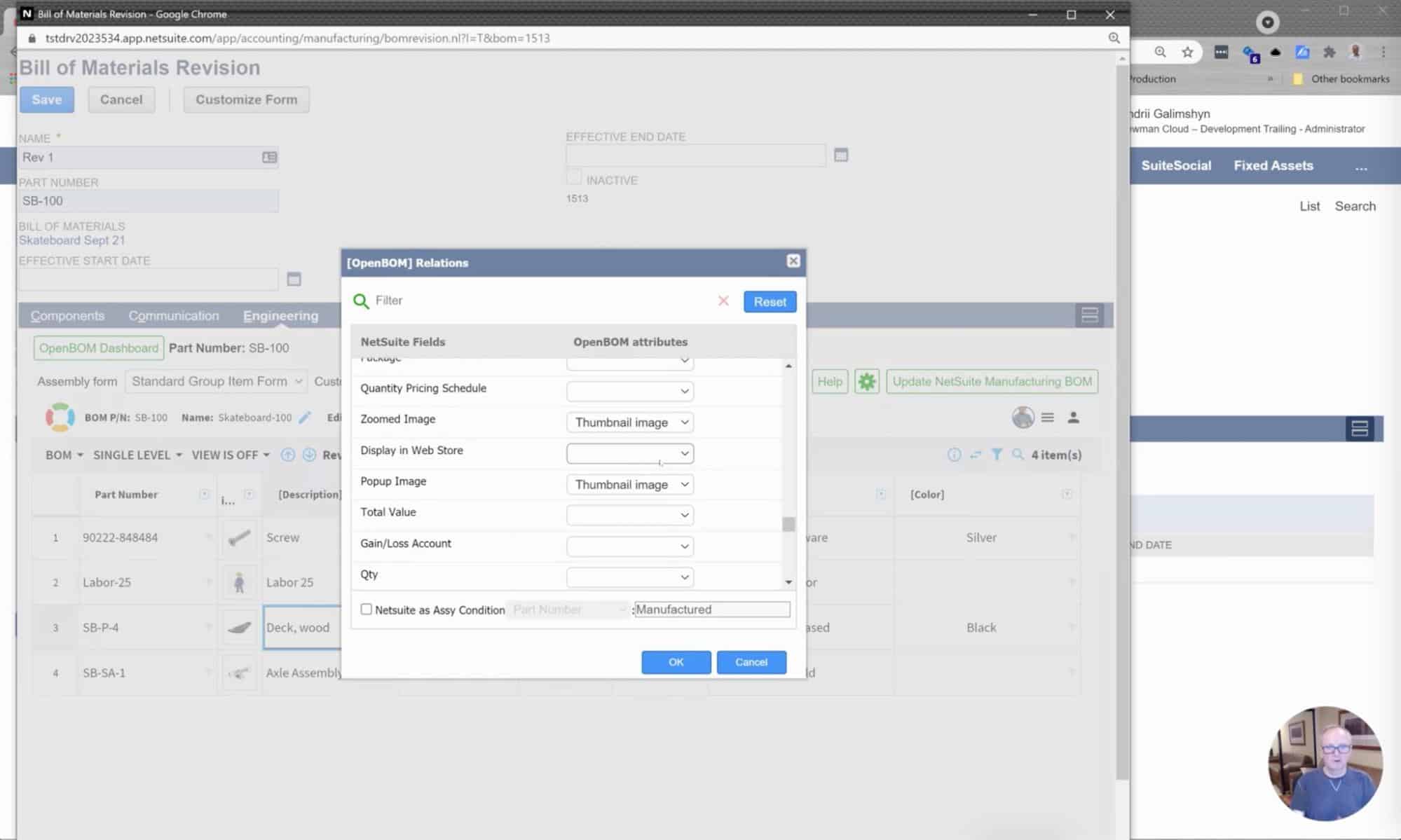

OpenBOM has a fully flexible data model that allows you to bring any data from CAD as well as add it directly in OpenBOM. Once the data set is established you can map the data to NetSuite using the flexible mapping user interface.

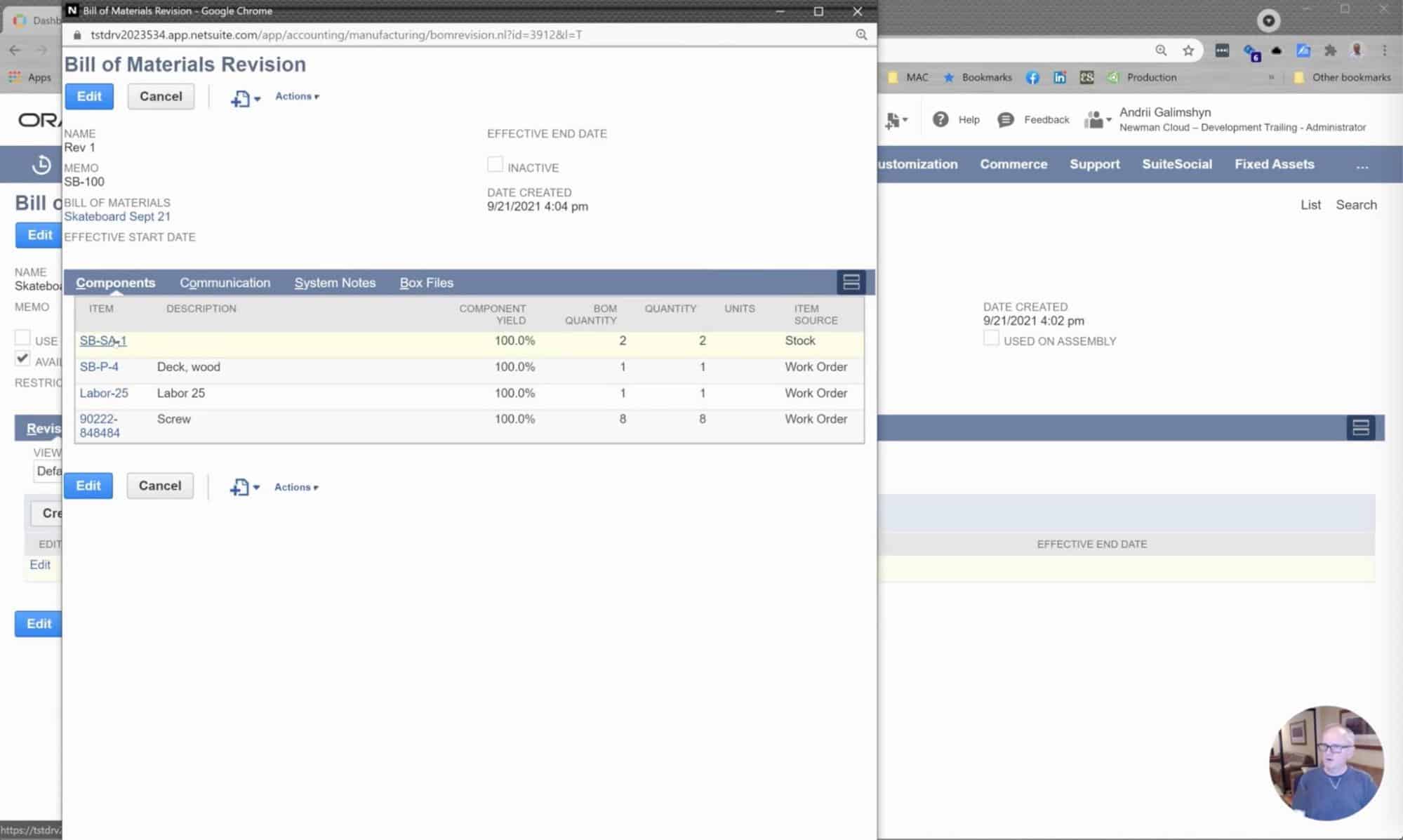

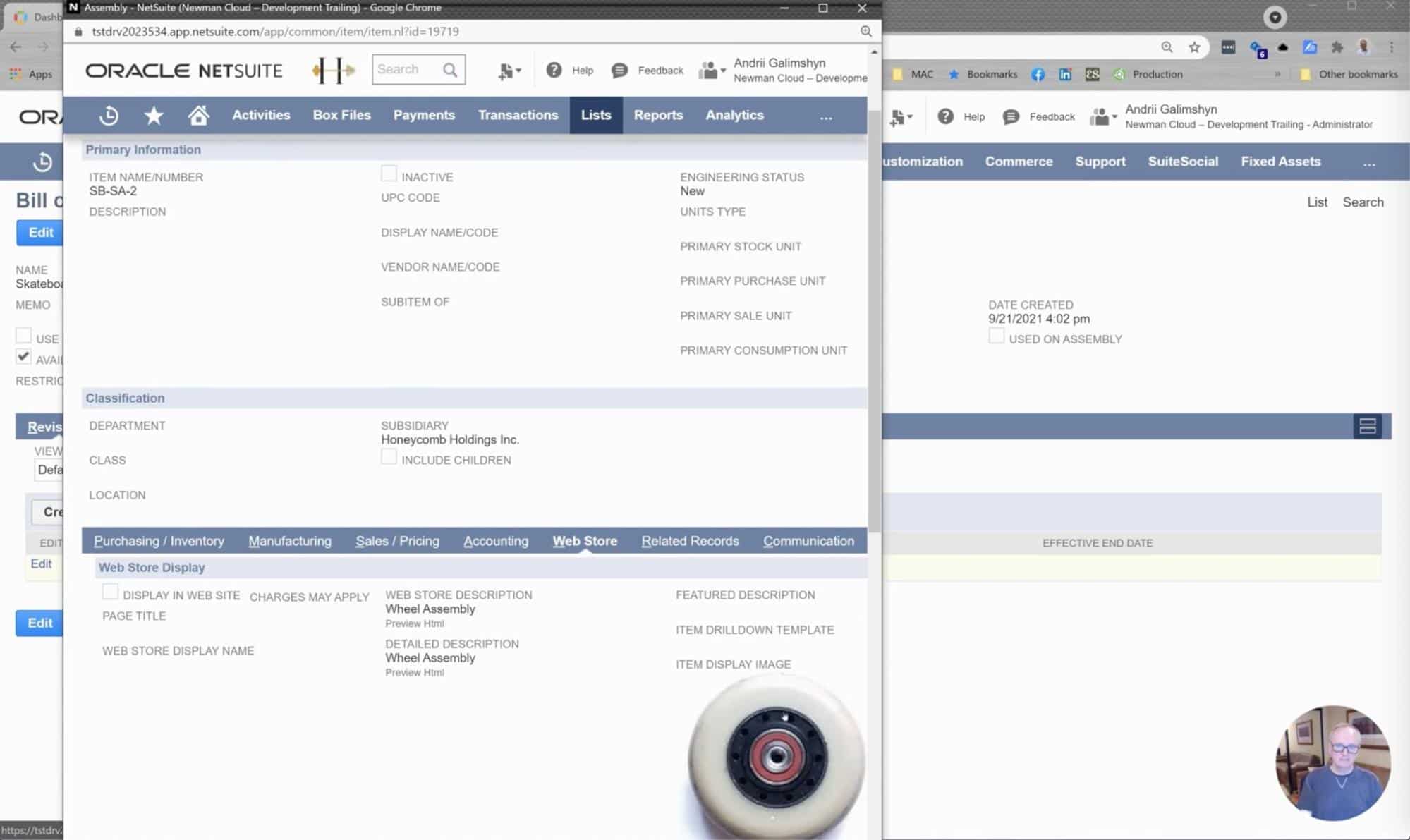

Once the data is mapped to NetSuite, a quick sync tool will send the data from OpenBOM to NetSuite. It allows for both simple and advanced manufacturing functions in NetSuite, sending various data types (text, links, documents, images, etc.) as well as establishing a multi-level Bill of Materials structure.

Here is an example of how images and data links from OpenBOM can migrate to NetSuite.

OpenBOM to NetSuite Video

Check out the following short video with an end-to-end scenario.

Conclusion

Manufacturing companies demand a connected flow of information that takes data from early design stages to production planning and procurement. OpenBOM is using modern cloud-based technologies to simplify integrations of CAD design, EBOM, and MBOM by helping our customers streamline their processes and connect information silos.

Check out what OpenBOM can do for you, register for FREE, and start your 14-day trial today.

Want to talk about your ERP integration project? Contact us – support @ openbom dot com.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.