The engineering and manufacturing world is moving away from the monolithic architectures of the past. Although current mainstream PLM platforms are widely adopted, I can hear the voices of many companies that are looking for “different ways to do business”. Although it won’t stop existing PLM business immediately, it creates a trigger for PLM vendors and customers to think about what is coming.

Breaking Monolithic Platforms

A famous quote by Ernest Hemmenguei says – “How did you go bankrupt?” Two ways. Gradually, then suddenly”. This brings many questions about Breaking monolithic Architectures into open services and how companies can break monolithic architectures.

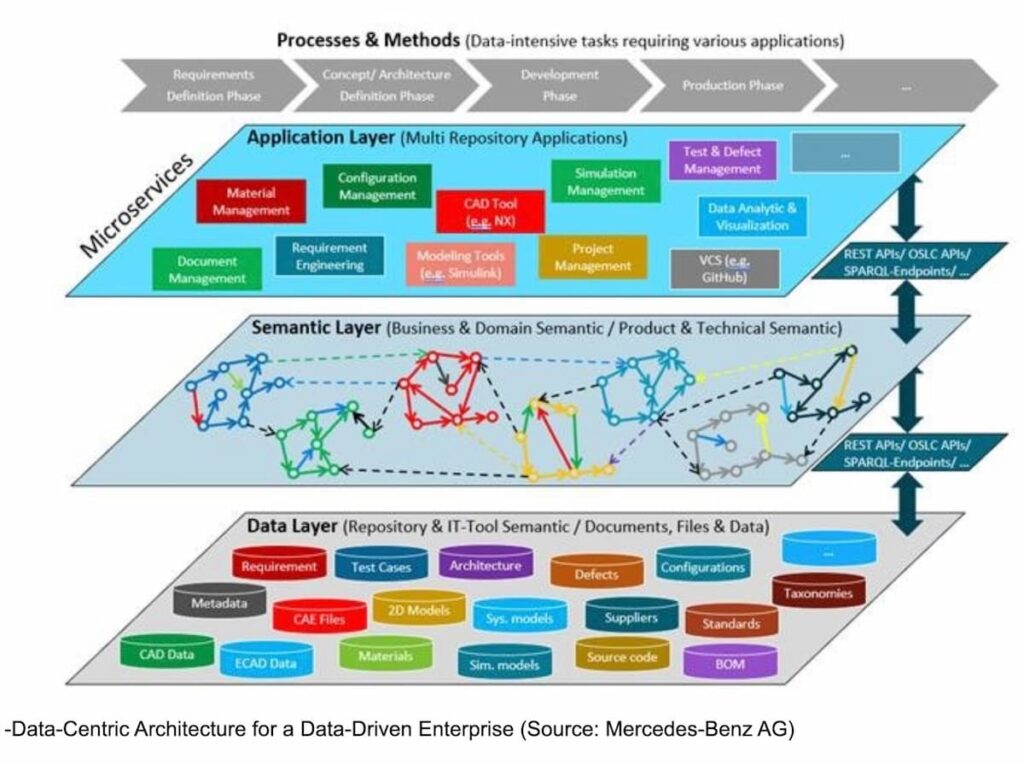

The idea of breaking monolithic tools is important. The picture below shows you the research work that is done by Mercedes Benz cars about how to organize layers of applications.

Another perspective of breaking monolithic applications is related to multi-clouds. While all established PLM vendors are suggesting how to turn their application suites into modern SaaS tools by adding “SaaS”, “X”, “+” and other signs to their product names, the real problem is that all these applications still use single tenant architecture and create isolated environments. Therefore, even if you get it run in the cloud (aka SaaS), the immediate problem is multi-cloud and how to integrate multiple applications running in different cloud environments.

Check my article Cloud PLM Technology 2023 – navigating the future and Integrating PLM platforms and multi-cloud future. As you can see there, one of the aspects is multi-cloud integrations that cannot be avoided and it is extremely complex.

Digital BOM Integrated Services Architecture

OpenBOM solves the problem of monolithic applications by bringing a new architecture of PLM applications. The three foundational principles of OpenBOM architecture are

- Multi-tenant architecture

- Real-time dynamic flexible data model

- Real-time collaboration and change management

These three principles allowed us to create a robust architecture and platform that can be used in combination with many applications and services

Another aspect of OpenBOM architecture is deploying reusable components and real-time integrations. These capabilities allow the integration of OpenBOM service into multiple applications. You can see examples of multiple CAD systems, PDM, and ERP applications. The same components can be used in custom applications too.

More examples:

Composable PLM Architecture

Gartner brings the vision of composable applications and composable architecture. Check this out – The future of the business is composable.

“ Composable business means creating an organization made from interchangeable building blocks” The organization created resilience via the principles of composable business — a key feature of a successful business in 2020 and beyond — that enabled the agency to provide a safety net for citizens in need.

“Composable business is a natural acceleration of the digital business that you live every day. It allows us to deliver the resilience and agility that these interesting times demand,” said Daryl Plummer, Distinguished VP Analyst, during the opening keynote at virtual Gartner Symposium IT/Xpo®. “We’re talking about the intentional use of ‘composability’ in a business context — architecting your business for real-time adaptability and resilience in the face of uncertainty.”

Composable architecture refers to a software design philosophy that emphasizes the modular assembly of interconnected components, where each component (or module) provides specific functionality and can be combined with other components to build more complex systems. This approach promotes flexibility and scalability, enabling developers to easily swap, upgrade, or modify individual components without disrupting the overall system. The concept is grounded in the principles of reusability and separation of concerns, ensuring that each component manages its own state and dependencies independently.

In practice, composable architecture allows organizations to adapt to changing requirements and technologies with greater agility. For instance, in a composable enterprise, IT infrastructures, applications, and services are broken down into smaller, manageable parts that can be deployed, maintained, and evolved separately. This not only speeds up the development process by enabling parallel workstreams but also reduces risk, as changes to one part of the system are less likely to impact others. Moreover, this architecture aligns well with contemporary development practices like microservices and can be enhanced by leveraging containerization and orchestration tools such as Docker and Kubernetes, which further streamline the deployment and scaling of applications.

How to invoke composable in a PLM context? Delivery of composable architecture in PLM, engineering, and manufacturing is complex because it requires building reusable blocks that can be combined together to provide services with specific functionality and predictable interfaces.

And this is a moment when OpenBOM architecture and technological principles are coming together. You can have a digital BOM component from everywhere, drop it inside of your existing applications and services, and get everything connected including old monolithic apps. The last is important because no one will ever plan to replace them.

What does it mean for business? You can check the last OpenBOM story with TTM Technologies and Bridge Appliance. In both, we demonstrate how OpenBOM can easily be integrated and used together with other applications and services. Here is an interesting passage:

“We had old BOMs, new BOMs, BOMs in Excel and others in text, many have become obsolete with time or were simply incomplete, others required tribal knowledge to be reusable, it wasn’t working and didn’t scale.” “We needed a lean flexible tool to record and organize legacy products while accurately documenting what we needed to build or buy.” “After evaluating several options, we purchased OpenBOM for several reasons. One – the Agile approach fits nicely into our internal processes; two – OpenBOM allowed us to quickly go from prototype to manufacturing, we could get the BOM to the shop floor right away, and three, OpenBOM has everything we need without the overhead and burden of what we don’t need.” “We really like the ease of use of the OpenBOM UX and UI. Our Operations team picked it up quickly, and casual users can return to OpenBOM as needed and be effective.”

Conclusion:

Engineering and manufacturing is changing. One of the changes is to deliver a new and modern architecture for PLM services that are capable of being integrated with other tools, but at the same time to be flexible to manage data and provide a modern user experience.

OpenBOM architecture is moving industrial companies forward. Try OpenBOM’s Free 14-Day Trial today and let’s discuss how you can transform your business using OpenBOM.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.