In the ever-evolving landscape of modern technology, staying ahead of the curve is essential for businesses seeking to remain competitive and innovative. One such advancement that has been gaining significant traction in recent years is the concept of a “knowledge graph.” This important technology is positioned to revolutionize the capabilities of modern Product Lifecycle Management (PLM) systems by enhancing their ability to capture and harness data from a multitude of sources.

In this blog, I will dig into the importance of knowledge graphs in today’s systems, particularly in the context of PLM. I will show how these graphs enable the seamless integration of data, track changes and updates from external sources, and provide a dynamic, event-driven mechanism that promises to shape the future of product development and management.

My attention was caught by the article published by Martijn Dullaart, a PLM and change management architect from ASML. The article speaks about Product knowledge graph and how it can track changes and semantic relationships.

I highly recommend you check out the article that outlines the importance of Knowledge Graph building and collecting both product and process knowledge together.

Knowledge Graph and Bill of Materials

Martin brings a very interesting perspective on how to use knowledge graph to manage product data. The examples can show you general principles on how graph technology can be used to capture information that traditionally was only managed by SQL databases in legacy PLM systems.

An interesting example shows how to capture BOM changes in knowledge graph.

My favorite passage (and conclusion) of the article speaks about how product knowledge graph is becoming a foundation of product AI LLM (large language model) :

By bringing product data and process data together, interesting patterns emerge that could help us further improve the way we develop our products, prevent corrective actions and delays, and improve the overall quality of our product data. While this field of research is relatively new, we can already see various opportunities for using this approach to start tapping into insights currently untapped. It will require a different way of thinking about product data, process data, process mining, and data analytics, but from where I stand that will be well worth it.

Another advantage of modeling the events in a knowledge graph is that Large Language Models (LLMs) can use these to be trained and find patterns. This will allow you to improve the quality of your impact analysis and implementation planning of changes as well.

OpenBOM Collaboration, Change Streams, Digital Thread and Knowledge Graph

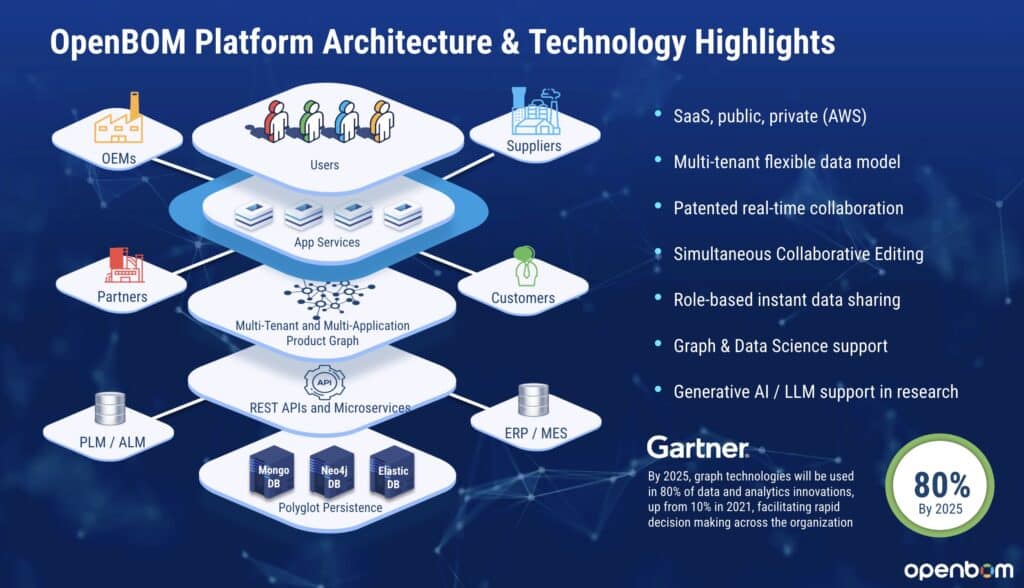

In my article today, I wanted to demonstrate OpenBOM technologies to capture changes and collect information using Product Knowledge Graph. OpenBOM data management foundation is using a combination of databases including Graph Database (Neo4j) to capture and manage product information.

In addition to that, OpenBOM has implemented real time collaboration using OT technologies to capture changes and translate them into product knowledge graphs.

The technology is delivered via product structure components that are used by OpenBOM web interface as well as all OpenBOM integrations with CAD systems and enterprise. Check out my blog from yesterday about OpenBOM Product Data Service and Components. You can see the overall OpenBOM architecture in the picture below.

In the video below, you can see how two browsers operate on the same data structure with different users, capturing changes and keeping collaboration going. OpenBOM data management services allow to inject information into product knowledge graph in parallel with user collaboration, so the entire data flow is combined together and product knowledge graph is updated from both user changes (eg. price change) and system changes (eg. CAD BOM update)

The example above shows you how OpenBOM technology works and gives you an idea how this technology can be used by customers as well as how the same OpenBOM product structure components can be embedded and used in different solutions by other vendors and customizations. Multi-tenant data model of OpenBOM allows you to quickly create an account and use OpenBOM service for your BOM data management embedded in your solution.

Conclusion:

Product knowledge graph is an important part of future PLM infrastructure and foundation of modern PLM software. Combined with multi-tenant data models and modern collaboration technologies, this approach can provide reusable components that can be utilized for building online (SaaS) software and also used as integration bridge between old legacy CAD and PLM systems and modern PLM technological stack.

Interested to learn more about OpenBOM technologies and how we can help you? Please contact us.

In the meantime REGISTER FOR FREE to check out OpenBOM online.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.