Among the various challenges that businesses face as they undergo digital transformation, one of the most common is moving away from legacy methods of exchanging data, such as CAD files and Excel spreadsheets. These old methods are often slow and cumbersome, prone to errors, and difficult to update. Seamless software can help you overcome these problems by allowing you to share data easily and accurately between different applications and platforms.

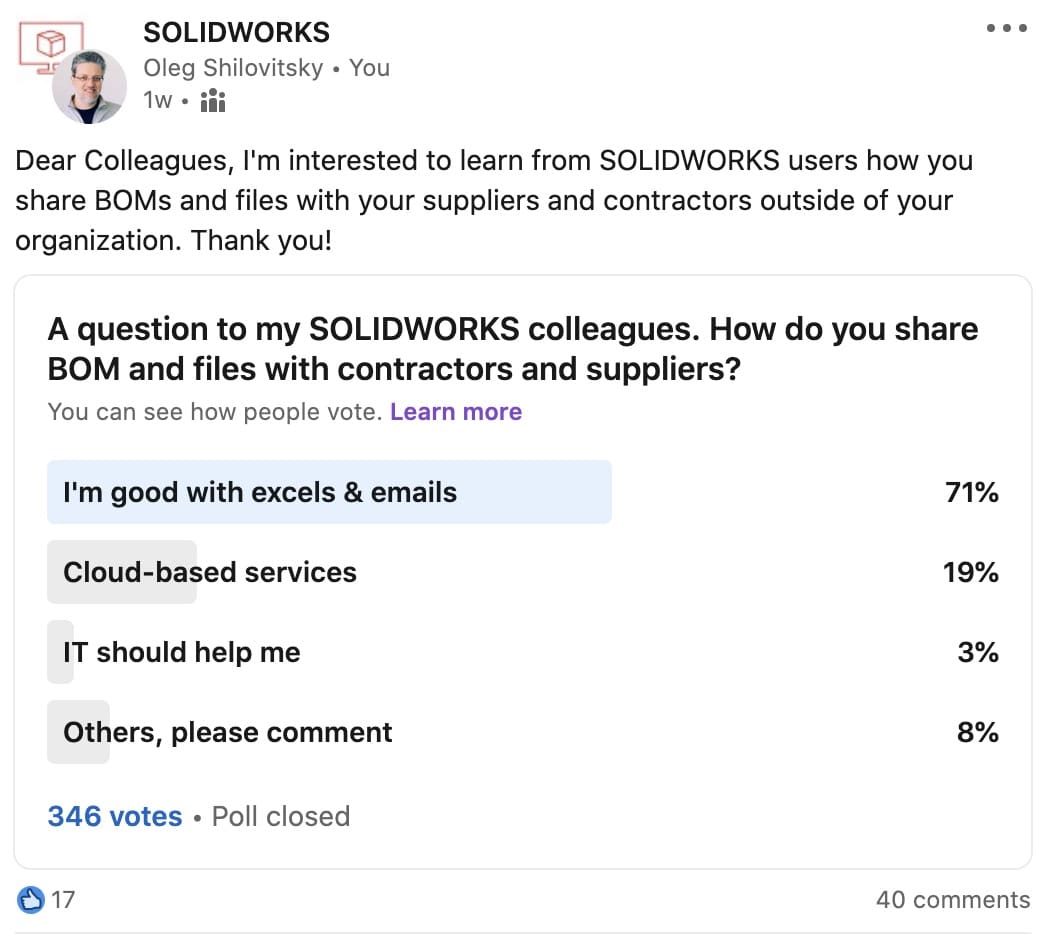

I was asking engineers using SolidWorks how they share BOM and related information and discovered an astonishing reaction – a large number of engineers using SOLIDWORKS are still emailing BOM Excels and sharing files via email.

While at the first glance you can think about it as “no problem”, things are great. After talking to some of them, I found a lot of details, very interesting reactions, problems and challenges.

Over-the-wall Manufacturing

Current data management is extremely fragmented and provides for many organizations, the main focus of their activities is to get data out to files (Excels, STEP, Zips) and send them to targeted places (usually a person who stands “next in the line” to get the information.)

The responsibility of engineers is how to get the data out, but their responsibilities are not converting any downstream processes. Therefore, for many of those engineers, it is very natural to think that shooting the file out will technically bring problems from one side to another. Engineers are not responsible for having a single source of truth or to take care of how the data will be managed in other departments and organizations. It is usually not the engineers’ responsibility to think about how the information is transformed later in the downstream processes.

5 Most Painful Problems

Although the data can be seamlessly exported, the complexity of tasks is fast becoming a heavy toll on engineers, their peers, and other members of the teams that must consume, organize and track changes. The problem is getting bigger with larger BOMs, complex SOLIDWORKS models, and other factors such as Part Number management and some others. Here is a typical set of problems:

- Not all data can be imported easily (names, attributes, quantities, etc)

- Exports and syncs take a lot of time.

- Large BOMs calculations

- Information is miscalculated

- Absence of a single source of truth

What engineers are missing?

One of the problems a company may experience is how to stop thinking holistically about the information and how data is flowing between different people in the organization, contractors, and suppliers outside.

Here is the set of best practices I recommend you consider for every engineering and manufacturing company.

- Start from baby steps, but focus on how the data is represented in the company

- Ensure everyone has access to a single source of truth, no fragmented information stays behind

- Ensure data is shared and not copied

Conclusion

Managing engineering and manufacturing data is hard and it can get very hard if you avoid creating a single source of truth. By throwing files and other information to the outside world you only create a bigger mess. The idea is to think holistically and focus on how to manage information streams in the company.

REGISTER FOR FREE to learn how OpenBOM can help you and your team today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.