When building prototypes, the focus is often on testing ideas, refining designs, and figuring out what works. Because of this, many teams treat the Bill of Materials (BOM) as something to worry about later. However waiting until production to create a BOM can lead to costly mistakes, sourcing issues, and unnecessary delays. It can also make the development process a bit messy.

A well-structured BOM isn’t just a production tool, it’s essential during prototyping too. It helps track materials, document design changes, and ensure each iteration is properly recorded. Without one, teams risk losing valuable information, making it harder to transition smoothly into manufacturing.

In this blog, we’ll explore why you need a BOM during the prototype phase, how it keeps your development process organized, and how it sets you up for a smoother path to production.

Capturing Changes Across Prototype Iterations

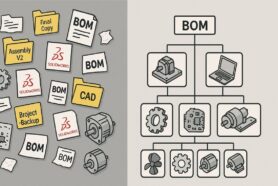

There are constant changes during the prototype process. The designs evolve, materials change, and components get swapped as you refine your product. Without a structured way to track these changes, teams can quickly lose sight of what’s been modified, leading to confusion, rework, and wasted resources.

A BOM during prototypes acts as a living document, recording every change across iterations. Whether you’re adjusting part dimensions, testing different materials, or swapping components due to availability, having a BOM ensures that each version of your prototype is clearly documented. This is especially critical when multiple engineers or teams are involved, everyone stays aligned on which parts were used and why.

Additionally, tracking changes in a BOM allows you to analyze what worked and what didn’t. If a certain material failed in testing or a component was difficult to source, that information is captured, helping you make informed decisions before moving to production. Without a BOM, these insights can get lost, leading to repeated mistakes and inefficiencies.

By maintaining a structured BOM from the start, you create a seamless record of your product’s evolution, ensuring a smoother transition from prototype to production.

Smoother Transition to Production

Moving from prototyping to production isn’t just about finalizing a design, it’s about ensuring that manufacturing can be done efficiently, accurately, and without unnecessary delays. A well-structured prototype BOM plays a crucial role in this transition by serving as the foundation for your production BOM. This transition often starts with the request for quotation (RFQ).

Without a BOM during prototyping, teams often scramble to piece together part numbers, sources, and specifications when preparing for mass production. This leads to inconsistencies, unexpected material shortages, and costly last-minute changes.

A BOM during prototype builds also helps procurement teams plan ahead. By identifying approved components and suppliers early on, long lead time parts can be accounted for, reducing potential production delays. It also allows manufacturers to review the design, suggest cost-saving alternatives, and flag potential manufacturability issues before they become roadblocks.

In short, treating your BOM as an evolving document from prototype to production saves time, reduces errors, and ensures a seamless handoff to manufacturing teams. Instead of rushing to create a BOM at the last minute, you’ll have a well-documented, production-ready version that makes scaling up much more efficient.

Managing Costs and Supply Chain Early On

During the prototype phase, there are costs associated with bringing these to life, significant ones. Without a clear understanding of materials, quantities, and suppliers, prototype expenses can quickly spiral out of control. A prototype BOM plays a crucial role in managing these costs early on, helping teams stay on budget and avoid unnecessary financial surprises.

By documenting every part and material used in the prototype, you get an early snapshot of the potential cost breakdown for your product. This allows you to identify expensive components early and find ways to either reduce costs or find alternatives. Additionally, you can assess the cost impact of design changes, making it easier to evaluate trade-offs between performance, quality, and price.

A prototype BOM also provides a clear understanding of the supply chain, helping you assess lead times, part availability, and supplier reliability. If a certain component has long lead times or is difficult to source, you’ll know this upfront, allowing you to make adjustments before these issues cause delays in production. Moreover, working with suppliers during the prototype phase helps establish strong relationships and ensures that they’re ready to scale when you transition to manufacturing.

In essence, a prototype BOM allows you to manage costs and minimize supply chain risks from the start. By tracking materials, quantities, and suppliers, you can proactively address potential issues and ensure that when you’re ready to move to production, everything is in place for a smooth, cost-effective scaling process.

Conclusion

While it may seem like the BOM is a tool meant only for production, its value begins much earlier, during the development and prototyping phase. From tracking design changes to managing costs and smoothing the transition to production, a well-maintained prototype BOM ensures that every stage of your product development is organized and efficient.

By capturing every iteration, aligning teams, and identifying potential issues before they become problems, you set the foundation for a smoother, more cost-effective production process. The BOM becomes not just a list of materials, but a vital document that guides your product from initial concept to full-scale manufacturing.

Investing time in creating and maintaining a BOM during prototyping may feel like an extra step, but in reality, it saves you time, reduces risk, and ensures that when you’re ready for production, everything is in place for success. Don’t wait until production to start worrying about your BOM, make it a part of your development process from the very beginning.

By:

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.