Manufacturing is quickly becoming a digital industry. The days of relying on paper blueprints and hand-written notes are gone. Today, manufacturers are using digital tools to design and produce products. This shift to digital manufacturing is known as the “digital thread.” The digital thread is a concept that has existed for a few decades, but digital transformation gave a new life and purpose to the digital thread.

Digital Thread

The digital thread connects pieces of information in the product lifecycle together. It starts with the product designer, who creates a 3D model of the product using computer-aided design (CAD) software. CAD data is organized in the so-called design data structure, which is simply a representation of design documents – CAD assemblies, parts, and drawings. CAD data is used to produce an engineering structure (often called EBOM) and used as a full product data representation. These two designs and EBOM are intertwined and pieces of design and engineering items are connected (thread). Releasing BOM will create immutable structures representing data that are then used for production planning and procurement, ordering, and actually making stuff. CAD data can be passed to POs as well as to work orders and CNC machines for production operations.

Digital Workflow and Logical Data Model

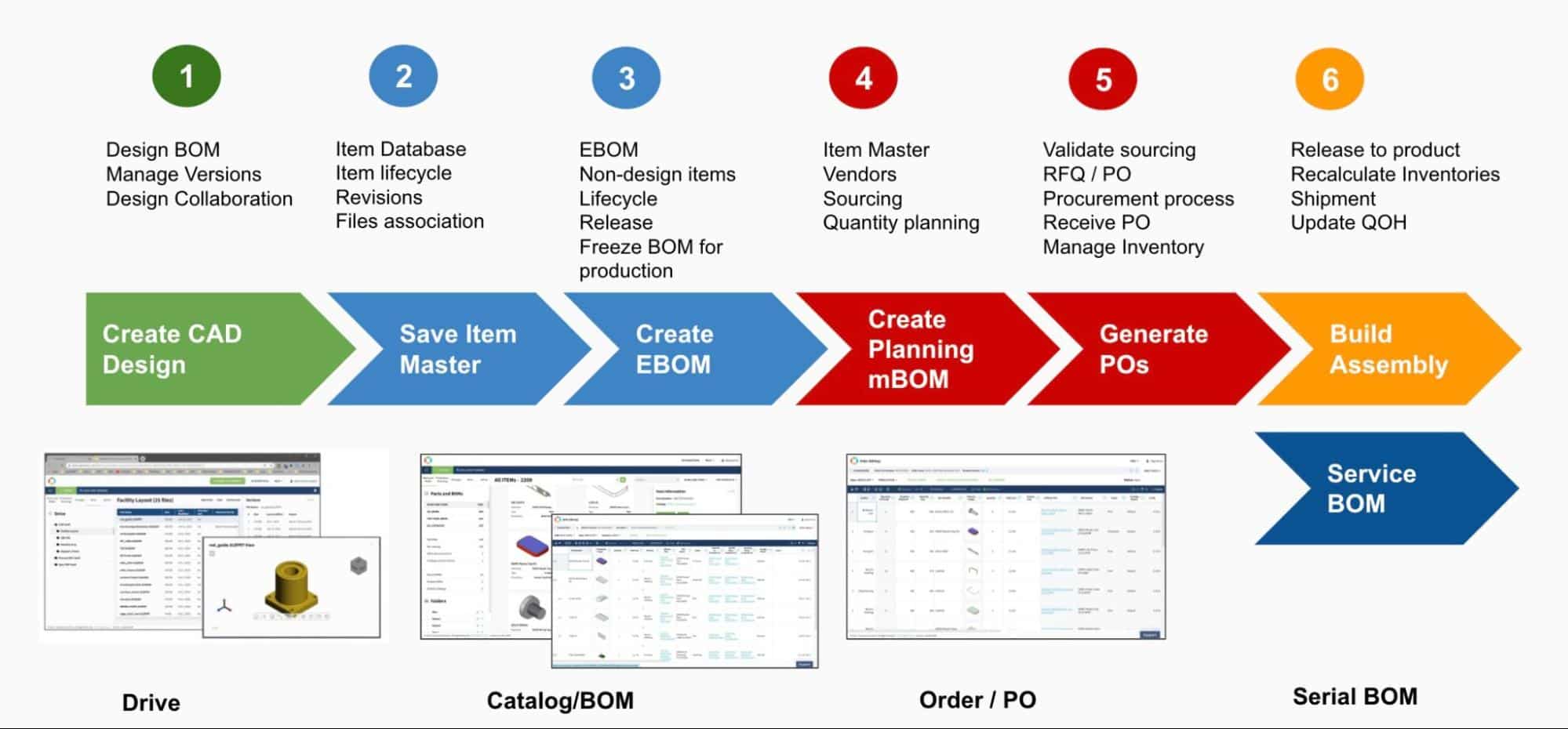

OpenBOM allows you to organize a fully digital workflow from the early design stages helping design engineers organize their CAD files, manage design versions, perform design collaboration, later create engineering BOM, attach documents, manage release processes, move data to production planning, manage POs and build final products to be shipped to customers.

The following picture gives you a full scope of OpenBOM Digital Workflow end to end supporting all stages of product development.

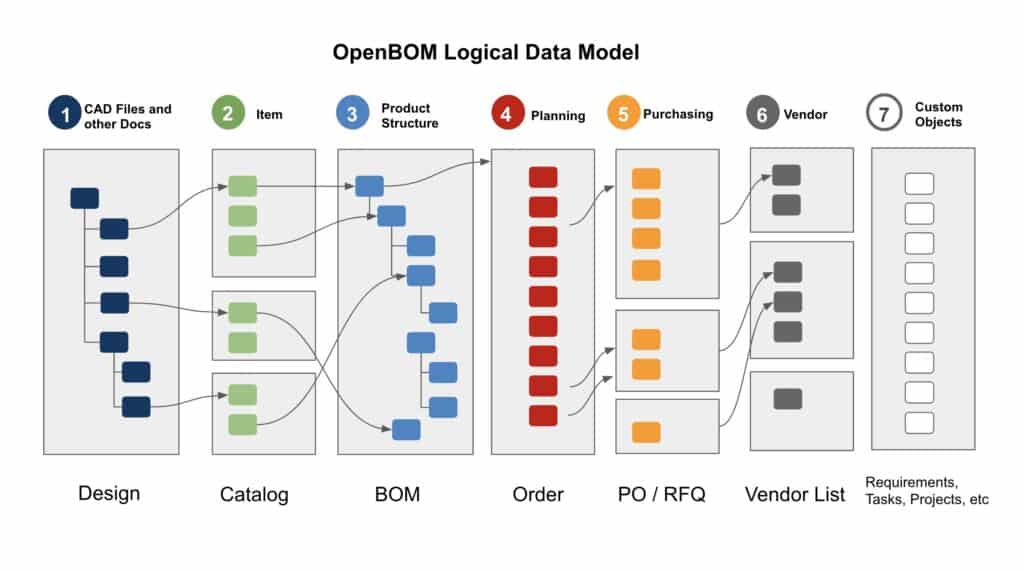

OpenBOM’s flexible data model provides tools and data management capabilities to create objects, manage relationships, and support data handover between multiple stages of product development and manufacturing processes. You can check out the following picture for full details.

OpenBOM dedicated services provide you with tools and support for each step in the logic model above.

In the article today, I will focus on a single aspect of digital thread and data management – how OpenBOM allows you to manage documents and connect them in the digital thread.

Design Files, Version Control, and Folder Structure

Unless you’re using cloud CAD and other cloud design tools, the outcome of your work is represented by files. These files represent a complex data structure about various objects – assemblies, parts, drawings, specs, and others.

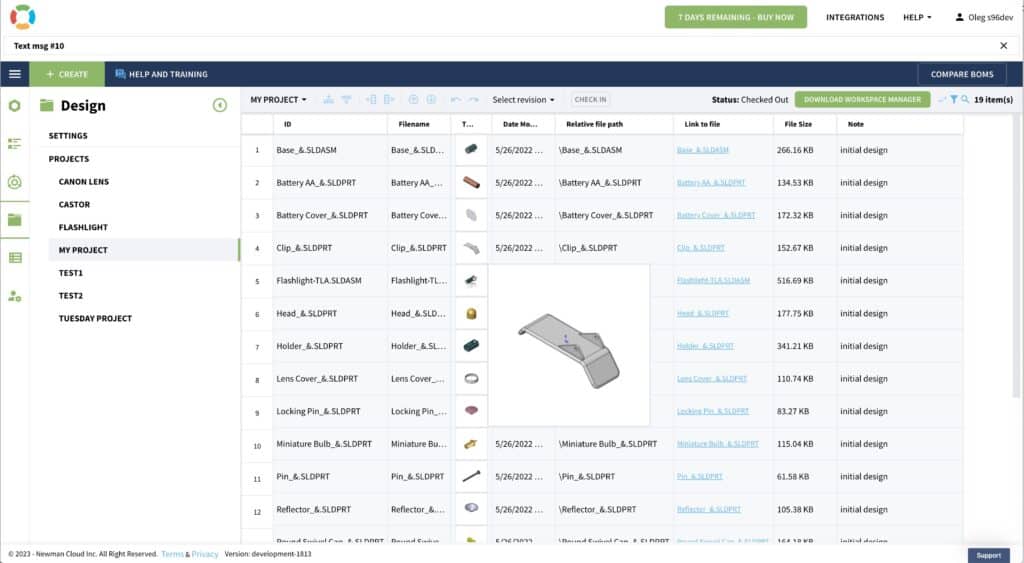

OpenBOM Design Projects is a dedicated set of OpenBOM functions (which will be introduced in the Sep/2023 release) to manage design files. It is part of the OpenBOM Free Subscription. It allows you to create Design Projects, upload, manage revisions, and keep in sync files between cloud storage and local folders. Check out more about OpenBOM Design Projects in our documentation.

Attaching Files to Items and Engineering BOMs

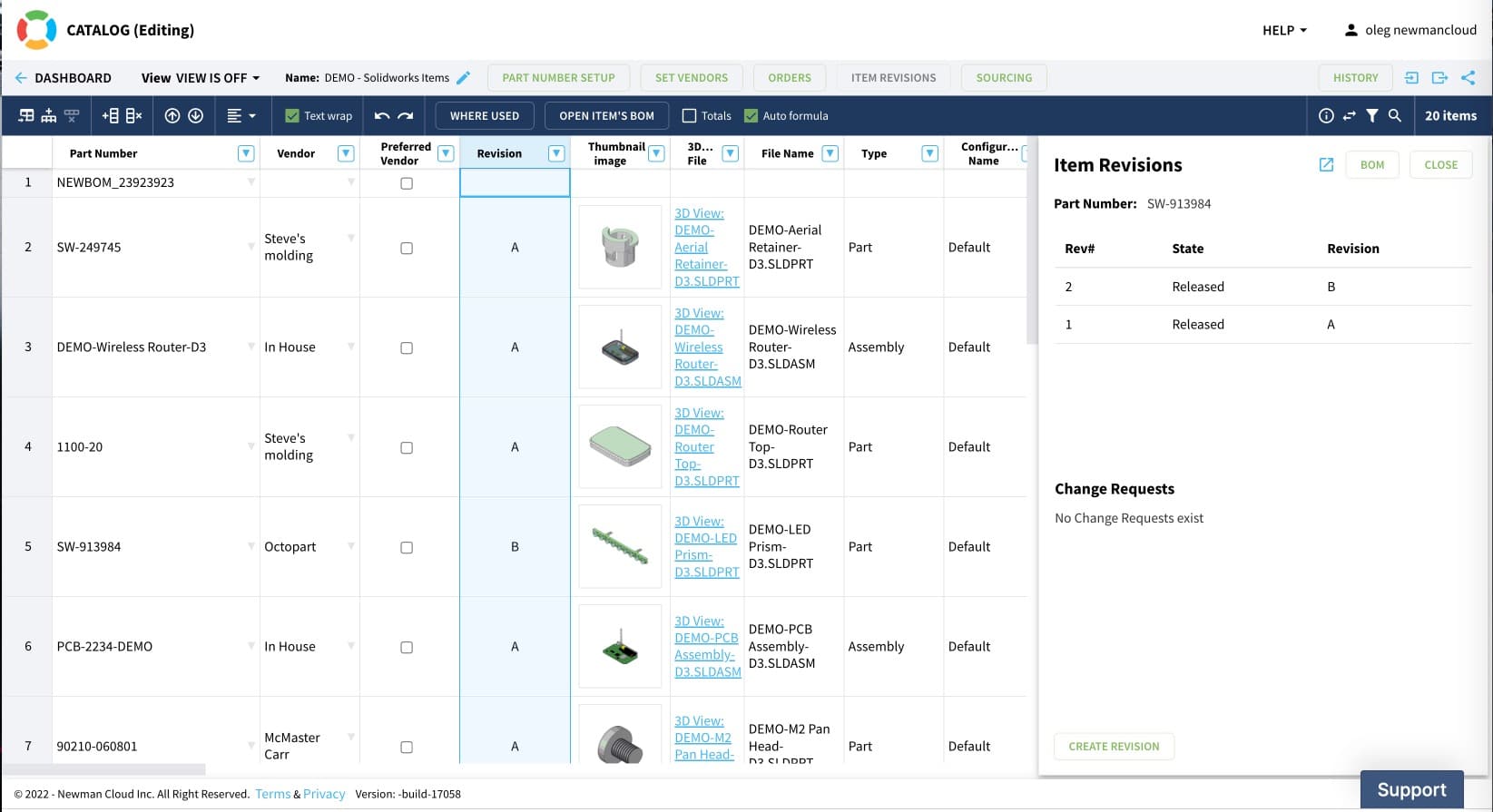

OpenBOM Catalog is a fundamental mechanism to manage items. Anything is an item in OpenBOM. It can be a screw, a chip, a custom mechanical part, and an entire assembly (electronic or mechanical). After all, a product is an item too.

You can use catalogs to create items and then use the BOM function to create a BOM. You can do it by mastering data manually or creating data imports directly from CAD systems and other data sources. Check out more about a variety of use cases here –

OpenBOM is managing documents using the Reference property type. By extending object records in OpenBOM using Reference property types, users can add documents to these records.

OpenBOM provides you with three main ways to manage documents

- Load file to OpenBOM integrated file storage (Default)

- Link to one of the configured cloud file storage (eg. Dropbox, Google Drive, etc.)

- Integrate with corporate file storage (only for enterprise subscriptions and custom).

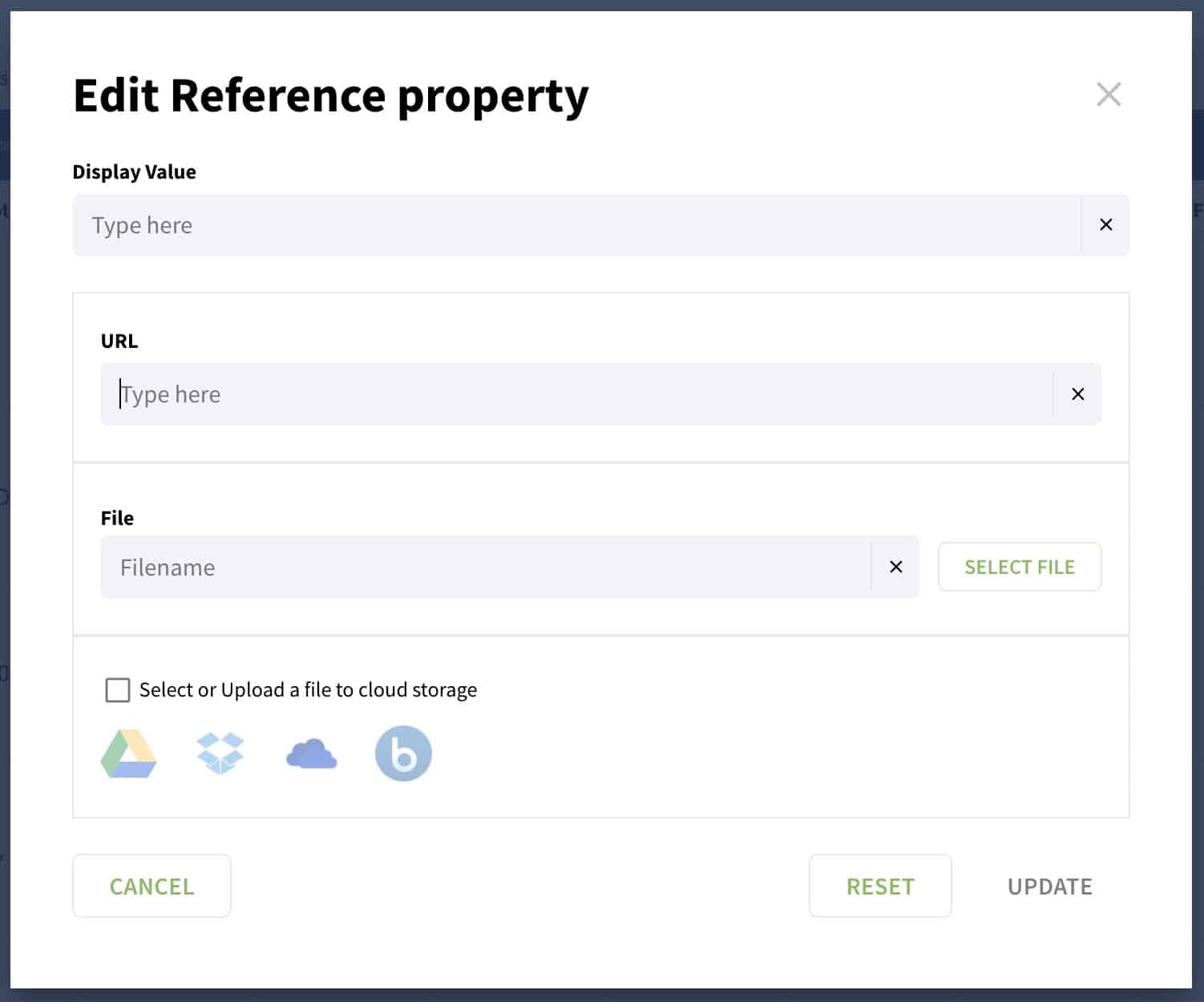

Reference Property

To attach a document (file) to BOM or Items, you need to add a property with Reference types. You can add as many properties as you need and by doing so, you can add as many files as needed. It provides a lot of flexibility because it is not limiting product records to only one file. Examples – add tech specification, drawing, and visual 3D file to an item record.

Read OpenBOM Property online document to learn how to use reference property type in OpenBOM. Navigate here to learn more. Using the reference property interface you can upload files to OpenBOM storage or upload data to one of the connected cloud files storage. Also, you can just put a link.

Item Revisions and Files

When you create a revision of the Item (and BOM), OpenBOM saves all item information in an immutable form in such a way that you will get access to all released information and track the history of changes.

Using OpenBOM Storage allows you to save the history of files attached to items and BOM in such a way that you will have a full product lifecycle history and changes. These files are saved in reference properties. By creating multiple properties you can manage multiple files attached to the same item.

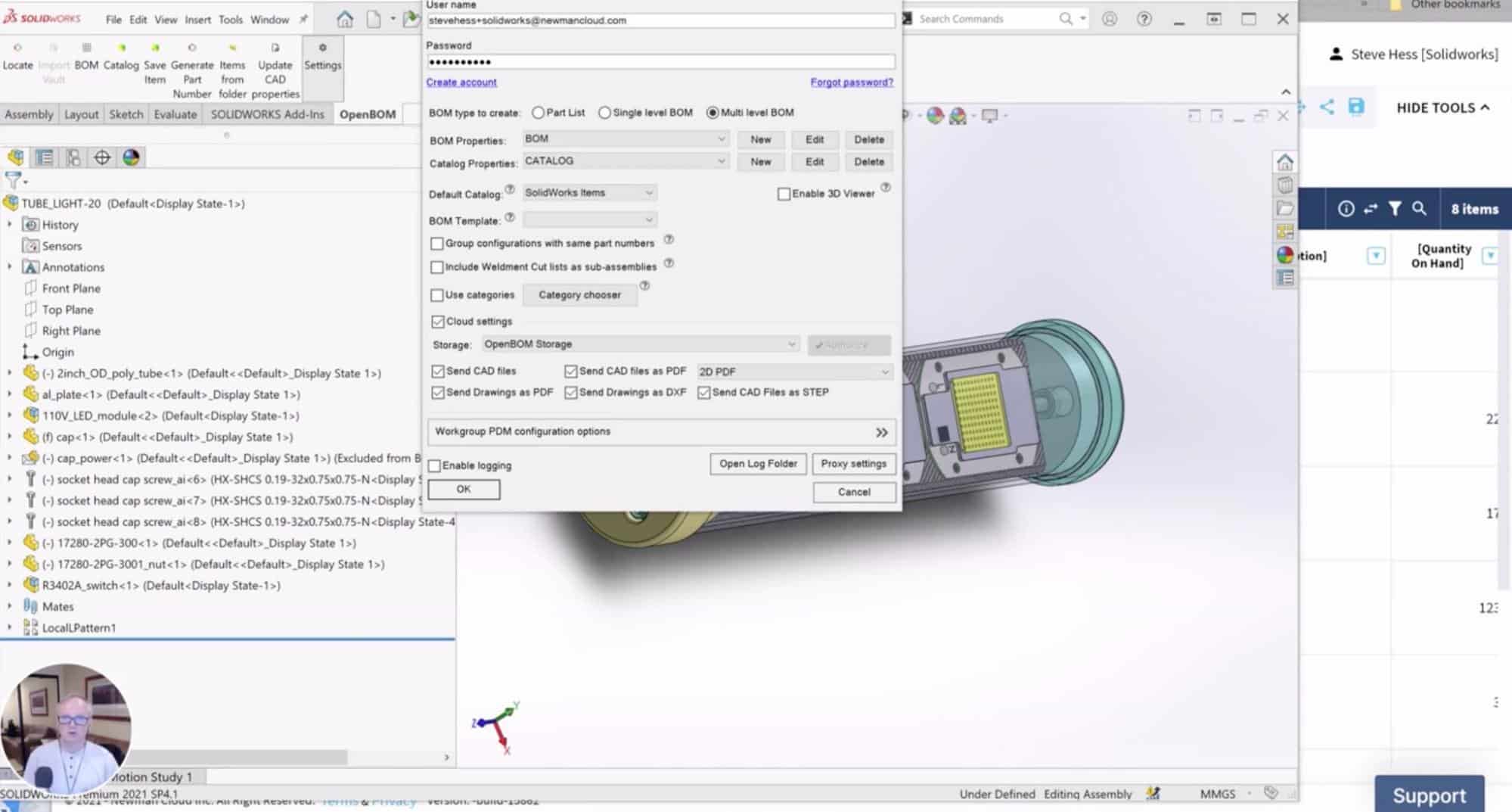

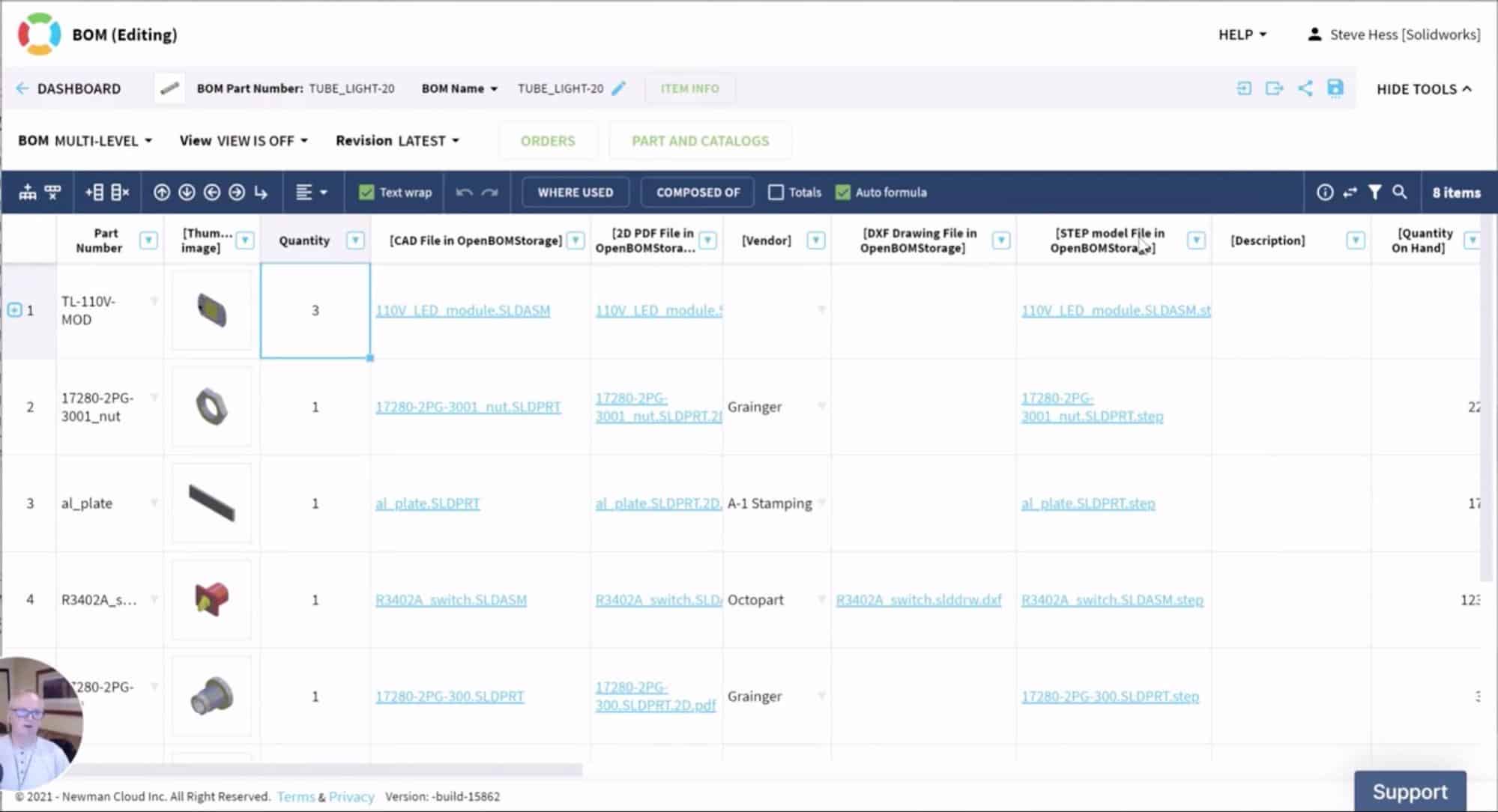

CAD File Derivatives

The same file attachment mechanism was used by Item. The OpenBOM Add-in Settings allows you to select formats of data you want to upload to the storage and connect it directly to Item records in catalogs(s) or BOM instances. OpenBOM will create a special property that holds the files and connects them to item records in the catalog(s). Here is a setting screen.

Once you’ve selected the option to upload DXF or STEP files, OpenBOM will automatically create these files during the BOM creation process and add the links to item records in the catalog(s). The data will become seamlessly available when you open the BOM or catalog user interface. When you share the information with customers, suppliers, and contractors they will get access to these files in a seamless way.

Check out the video below for more information.

Conclusion

OpenBOM provides a flexible yet powerful way to manage documents in different formats in different stages of the product lifecycle and for different purposes. Starting from just grabbing your files and dragging them to OpenBOM Drive will give you an instant mechanism to manage file versions and collaborate with the design team.

OpenBOM Items is the universal database of product information and you can use file attachments to connect the information to items and BOM to be more accessible downstream for production and procurement planning, manufacturing, and purchasing. You can easily share a native file or connect derivatives – (CAD, PDF, STEP, etc.) files. The files can be stored in OpenBOM storage – no special skills are required. Altogether, the information can be released for production and used as a historical reference for CAD files included in Items and BOM.

REGISTER FOR FREE and check out how you can use OpenBOM Drive today to replace files, excels, emails, and complex PLM solutions.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.