Ever since Excel and Spreadsheets were created, manufacturing companies have been sending these to their contract manufacturer (CM) or supplier. Even in the digital world, spreadsheets still seem to be the preferred option when sharing your bill of materials (BOM) with contractors and suppliers.

The only reason for this is that it’s been done this way for so long.

When you start the request for quotation (RFQ) process, it is very common to send a zip file. In this zip file, you have the spreadsheet or excel BOM, drawings, specification sheets, a product introduction sheet, and other information needed for the quotation, such as the volume and annual forecasts.

While all of this information is great, it is also all independent from each other, nothing is connected. Meaning if you are looking at one part of the BOM, you’ll need to dig for the drawing, specification sheet, and more. You can’t really attach a STEP file or a spec sheet to your BOM.

It takes a good amount of time for your supplier to compile all of this product data. Needless to say, it can take days for your CM to go through the product data without moving forward with the quotation.

This is why it’s common to receive feedback about a week after you send your CM your product data.

Why a Digital BOM?

The purpose of a digital BOM is to improve the way you communicate and work with other team members, and in this topic, your CM. The digital BOM connects you with your team and contractors while also creating a single source of truth.

Here are three reasons why your CM would rather have a digital BOM than an excel BOM.

Central Database

The most common reason your CM prefers a digital BOM is that it brings all of the information together. Instead of having to dig for the STEP (product drawings), product specifications, and other product data, it is connected to the BOM. Therefore, taking you seconds to find the drawing, rather than minutes. And if your product has multiple parts, this time adds up.

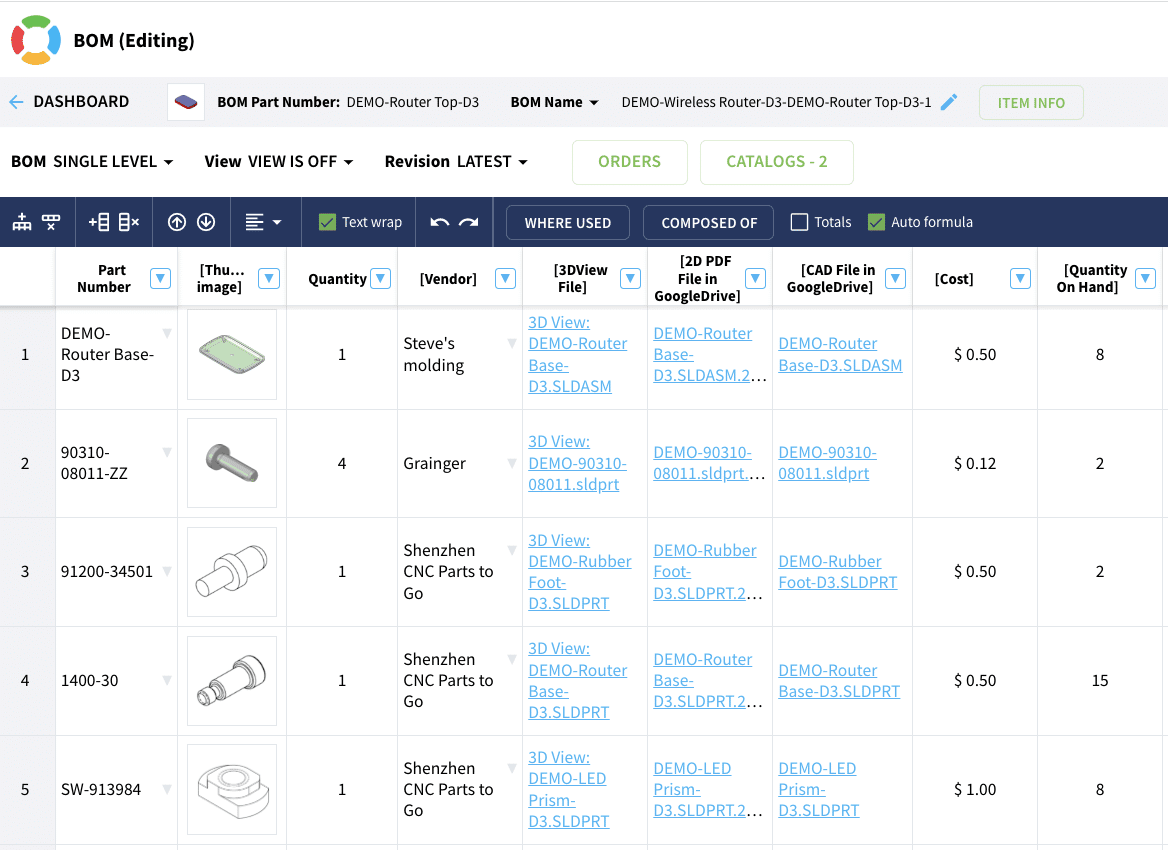

The BOM shown below is made for the digital world of manufacturing. Besides how simple it is to read and identify, you have CAD files and 2D PDFs that you can’t have with an excel BOM. Also, with a digital BOM, when the parts update, so are the attached drawings, creating the centralized database you need.

This BOM will improve your CM’s efficiency when they are searching for the relevant information to provide you with that original quote.

Real-Time Sharing

Emails back and forth served their purpose and are the only way to really send an excel from one place to another. But this creates chaos and makes it very easy for you to lose track of who has what. Emails back and forth also make it difficult for your supplier. They need to download this data and send it to their team and sub-tier suppliers. It’s very easy for them to forget what they have and what they need.

The digital BOM eliminates the need for these emails back and forth. Instead of waiting for the latest BOM revision to be sent via email, the digital BOM will automatically share data which improves collaboration.

Manage Revisions and Changes

When you send product data to your CM for a quote, you will most likely have changes made to the product. There are a few things important with these changes.

- Historically capturing these changes

- Have an approval system for the ECO process. Meaning your supplier can request changes but not approve them.

- Re-distribute the newest data.

With an excel BOM, you are unable to accomplish any of these. You can only track the history from previous BOMs. Anybody can make a modification to the BOM without you or anyone else approving it. And lastly, you can not automatically share your excel BOM.

If you provide your CM with a digital BOM, you will be able to easily track revisions and changes, and the BOM is instantly shared with all members of your team. No more emails, or messages back and forth asking for the newest BOM with the most updated changes.

Essentially, an excel BOM will slow down your product launch. Your CM is looking for ways to improve their efficiency and to provide you with more support. Giving them a tool, such as a digital BOM will drastically help them to provide you with more value.

What can you do today?

If you are looking to improve the relationship with your CM, then digitalizing your BOM is a great step. The digital BOM will keep all of your product data together and manage your revisions and create an ECR/ECO process. Your solution is a centralized platform that connects your team, contractors, and suppliers.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.