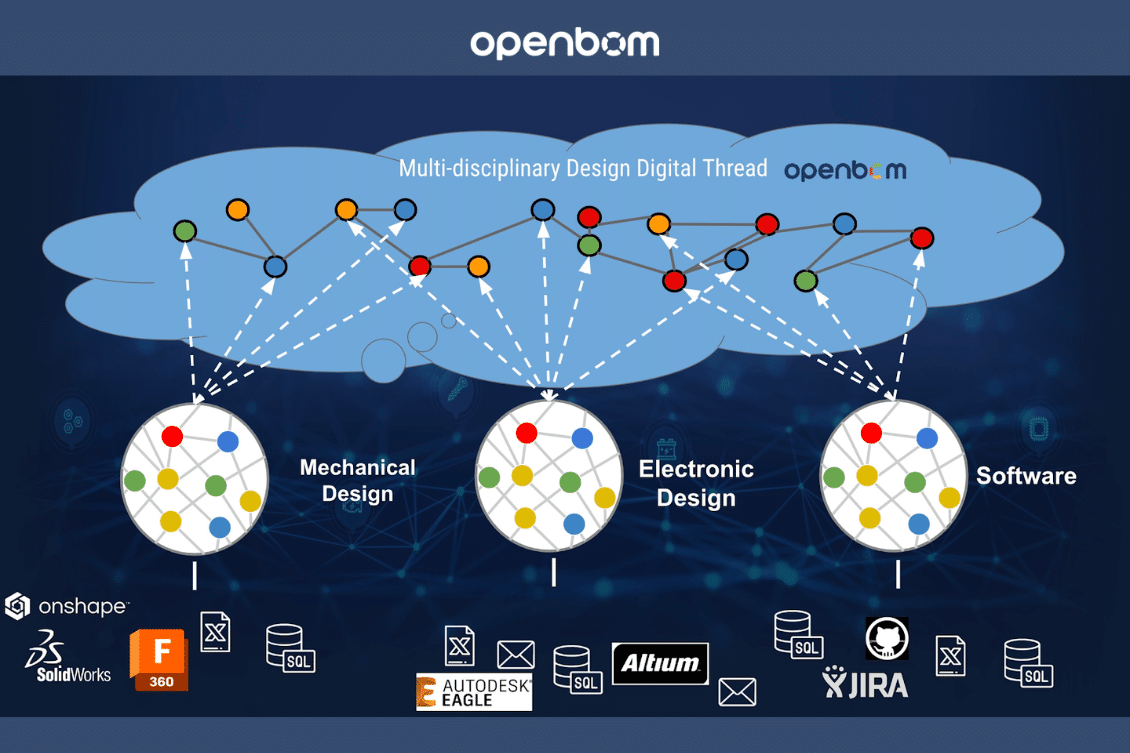

The world of product development and manufacturing has been experiencing significant transformation. As our understanding of technology evolves, so does the complexity of modern products. Every modern product today requires the integration of various disciplines, including mechanical, electronic, and software design. This shift necessitates a more comprehensive, multidisciplinary approach to managing the complex data structure and lifecycle of information involved in product design and manufacturing processes. For the last two decades, traditional PDM tools evolved into siloed solutions that focused on a specific CAD System. You can get a separate data management system for Solidworks, and Altium or you can get GitHub which is amazing for software development. However, pulling all these things together requires more than running all these siloed environments separately.

The Multidisciplinary Nature of Modern Product Design

Modern product design is an intricate blend of various disciplines. A smartphone, for example, is not just a simple assembly of mechanical parts; it also incorporates sophisticated electronic circuits and software that enable its numerous functions. This convergence of multiple disciplines implies that product design has become a collaborative process involving various teams, each with its unique data and information requirements. Managing this multidisciplinary information structure becomes a significant challenge.

The complexity of the product development process is multiplied by geographical and organizational distributions. Teams, Suppliers, and Contractors – all located in different places and different countries. Managing all of them takes effort and a special level of complexity.

The product development process can no longer rely on siloed data structures or isolated design tools. Instead, it requires a flexible, dynamic, and inclusive digital information model capable of capturing and managing the vast array of product information across all these disciplines.

Managing the Product Graph and Integrating with CAD tools

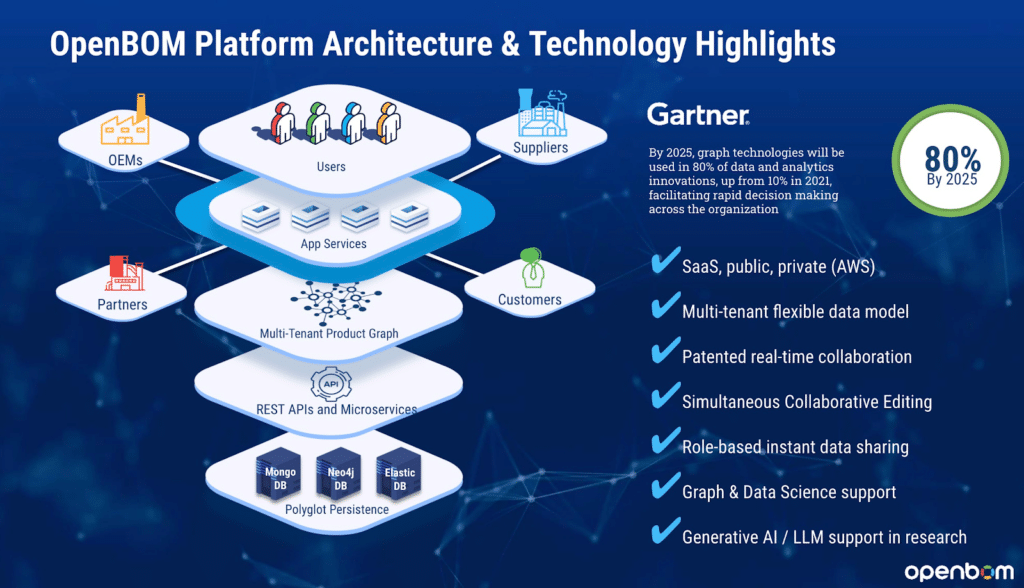

From the early days of OpenBOM, we designed it to be a global platform available to multiple companies at the same time in different geographical zones. The core foundation of OpenBOM is using multiple data management technologies including graph databases to manage flexible data models and relationships between all elements of product design. It is capable to manage flexible product structures and capture design information effectively.

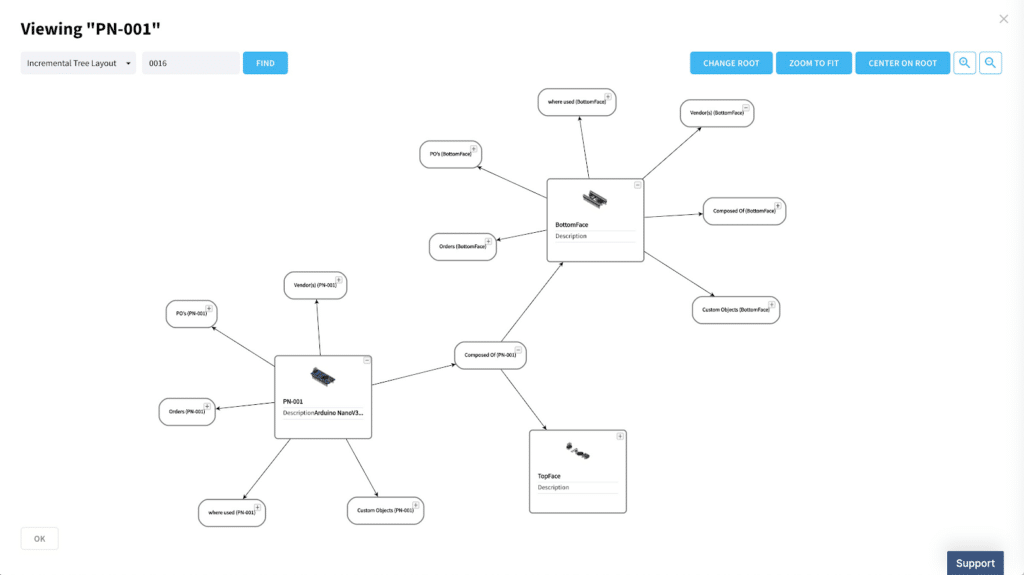

At the foundation of OpenBOM is the Product Graph, a powerful data structure that captures the intricate relationships between various components and subsystems in a product. This graph presents a hierarchical and relational view of the product, enabling designers to understand and manage the complex dependencies in a product design.

OpenBOM soon will allow users to visualize complex data structures (tip: stay tuned for the Graph Navigation feature coming)

Design Integrations (MCAD, ECAD, Software)

The OpenBOM Product Graph is not limited to just mechanical components; it can encapsulate electronic components, software modules, and other entities in a product, effectively bridging the gaps between mechanical, electronic, and software design.

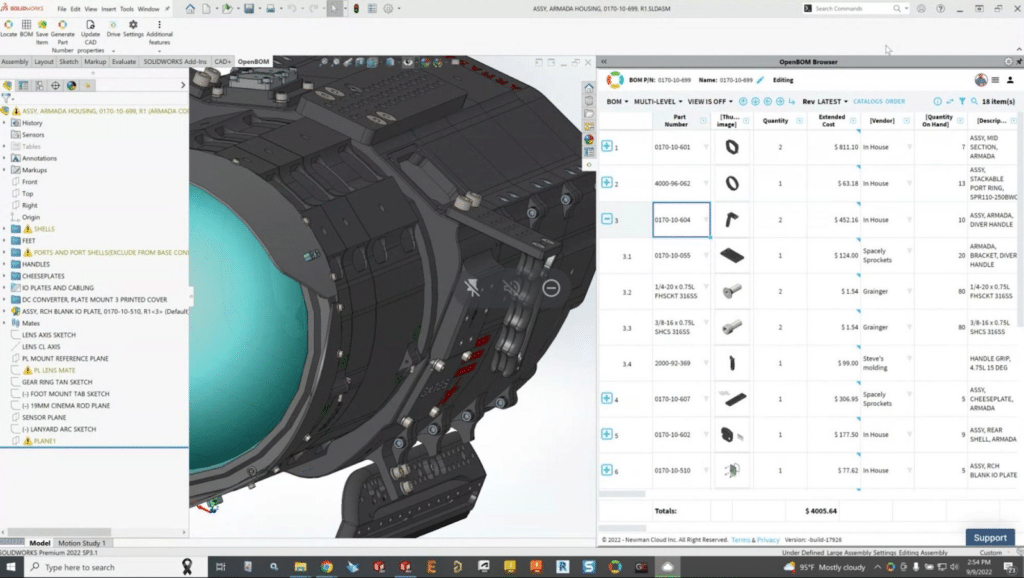

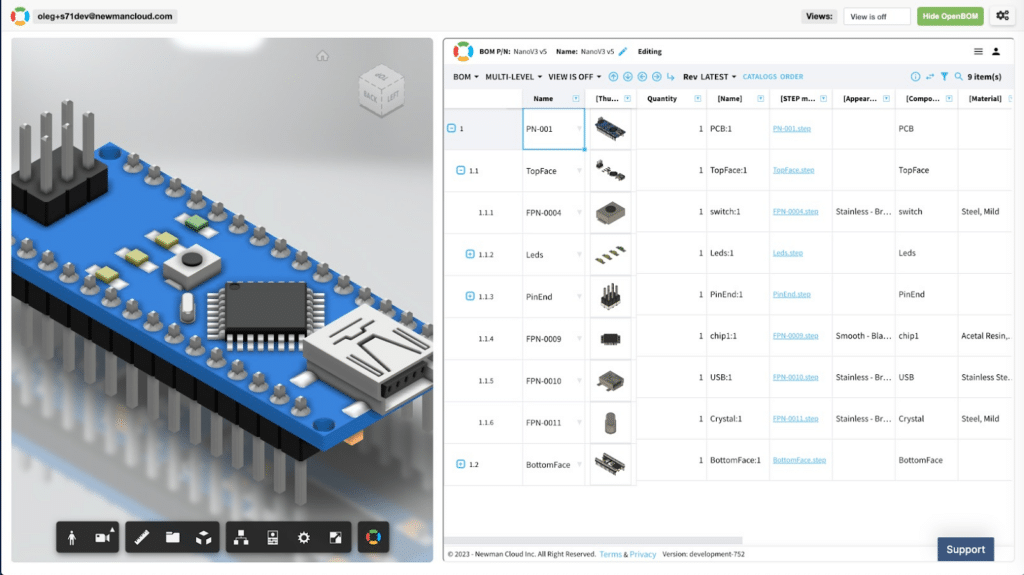

In the pictures below, you can see how OpenBOM integrates with a variety of design systems. The full list of integrations is available online.

Here are examples from Solidworks, Autodesk Fusion, and Altium Designer.

Conclusion

The era of siloed design approaches is long past. The time when you could have been managing CAD files and saving data in Excel is also numbered. The multidisciplinary nature of modern product design necessitates a unified, robust system to manage the resulting complex information structure. The data OpenBOM manages makes it possible to use agile methods in product development. OpenBOM, with its flexible product graph and robust integrations, provides an effective solution to manage the design digital thread, catering to the needs of modern manufacturing companies and the complexities they face.

REGISTER FOR FREE to check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.