Nothing is constant, but changes. In engineering and manufacturing organizations, change orders (ECOs and MCOs) are a necessary part of the product development, manufacturing, and maintenance process. A change order defines a formal process of the design, production, or already physical product.

In this article, we start a series of blogs that speaks about how OpenBOM can help manufacturing companies manage engineering change orders, create a change report, maintain change history, connect them to CAD files, save revisions, create change requests, organize data sharing in engineering teams. The tools OpenBOM provides are the foundation for configuration management in every manufacturing company and contract manufacturers.

The Need For Digital Transformation

Every company has its Change Order processes organized. But the way it can be organized might be different. A paper trail is one of the oldest ways to organize a formal process. You create a paper with the description of the change, list the number of items in the table below, and send it to approvals. A corkboard can be another ancient way to manage changes. The process can sometimes look very ugly.

Digital transformation is coming to all manufacturing and companies are looking for ways to automate and optimize the ways to manage changes and organize the overall product data management process.

Collaborative Data Management Environment

In OpenBOM, engineers, production planners, contractors, managers, and everyone else in the company can manage data and organize the process of revision and change management in a flexible way. OpenBOM data management platform provides a flexible way to organize the data for items, bill of materials, create revisions, share information with other people in the organization using role-based access control. A single source of truth for product data is the foundation of efficient change management, which supports the identification of items, traceability of revisions, and organization of the approval process.

End-to-End Change Management Process

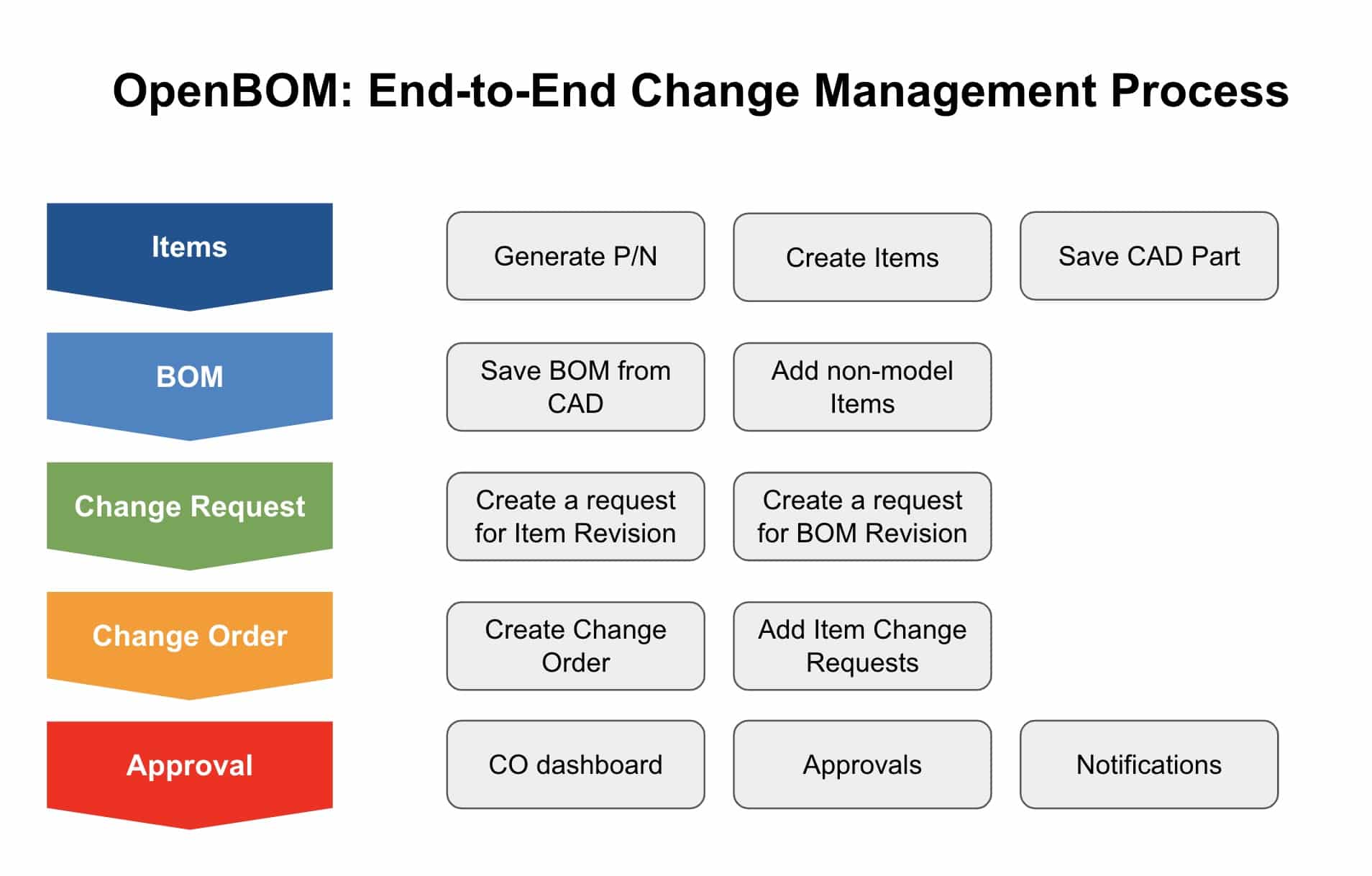

In the picture below, I outlined five steps in the process of how OpenBOM configuration management is organized and describe each step separately.

Items and BOMs are the foundation of product data. OpenBOM allows you to create items and related data manually as well as automatically by extracting the data from CAD systems, supports automatic data synchronization and updates. This is a core foundation of product data management and change history.

Change Request is a granular mechanism that manages the smallest group of changes such as change of parameters of an item (eg. Description, Material, Cost, etc. ) or Bill of Materials (eg. Quantity of an Item in a BOM).

Change requests and change orders are the foundation of the approval mechanism in OpenBOM. While change requests represent granular changes for a specific Part Number, Change Orders allows you to group change requests together for routing and approvals by team members.

The approval mechanism in OpenBOM allows specific team members to approve or reject the change order. A new sign-off dashboard is on the way and it allows for the collection of approvals and feedback from team members in a real-time collaborative form and helps you configure and manage notifications to specific team members or an entire team.

Video – Change Management Introduction

In this video, Steve Hess, OpenBOM director of user experience will give you an introduction to Change Management and OpenBOM Change Order dashboard functions.

This is the first video. In the following articles, we will speak in detail about every step in item management, BOM, and change management, explaining how to change requests and organize change orders. We will also give you a sneak peek at the upcoming OpenBOM Collaborative Sign-Off Dashboard.

Conclusion

OpenBOM is growing the support for change order management and provides a robust mechanism to manage items, BOMs, revisions, change requests, and approvals. These are core elements of configuration management in an organization and OpenBOM provides a flexible, yet robust mechanism to do so. Are you looking for ways to manage ECOs / MCOs, to coordinate approvals by CMs and suppliers? Then OpenBOM is a tool that can help.

REGISTER FOR FREE and check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.