In Part 1 of this series, we introduced the concept of OpenBOM’s Collaborative Workspace and how it enables efficient product data management including revision control and change management. We discussed how OpenBOM moves beyond traditional PDM systems by leveraging a cloud-based, distributed, and multi-tenant architecture that allows seamless collaboration across engineering, manufacturing, and supply chain teams. Most importantly, we discussed how change management introduced in OpenBOM Collaborative Workspace is different from a traditional check-in/out and revision control

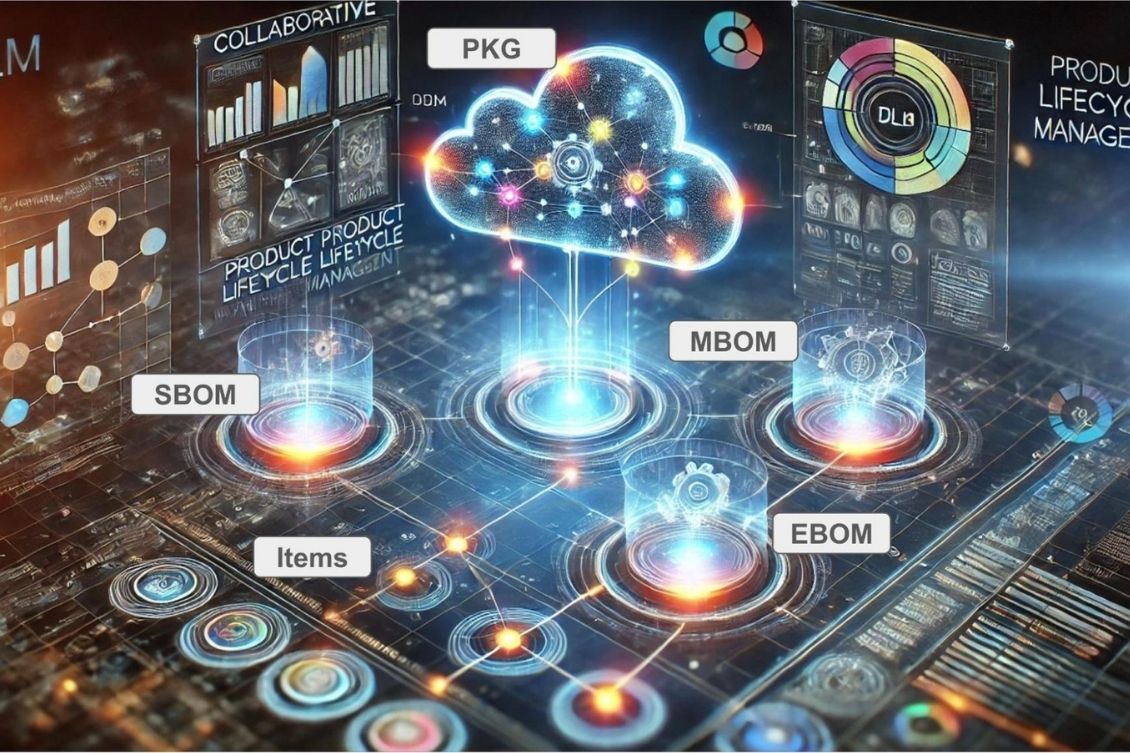

Now, in Part 2, we dive deeper into the three key elements of product knowledge graphs and explore how OpenBOM structures and organizes product information for different aspects of product engineering and lifecycle.

Three Elements of Product Knowledge Graph in OpenBOM

OpenBOM provides a structured approach to managing product data, enabling seamless collaboration and data continuity across the entire product lifecycle. This is achieved through three fundamental layers:

- Item Records – A flexible data model for classifying, managing, and interlinking product components, subassemblies, and associated metadata.

- Generic Product Structure (BOM) and Multi-Disciplinary Product Knowledge – A hierarchical data model that supports various item types, attributes, and cross-domain relationships within a structured Bill of Materials (BOM).

- Lifecycle and xBOM Support – Extends the standard BOM model to support multiple BOM types, including Engineering BOM (EBOM), Manufacturing BOM (MBOM), Service BOM (SBOM), and Maintenance BOM, ensuring end-to-end data consistency throughout a product’s lifecycle.

Beyond these three elements of data management, OpenBOM supports a flexible data model to organize various linked data objects for rich data representation, data federation, and extended data management.

Let’s explore each of these elements in detail.

1. Item Records – The Foundation of Product Data

At the core of OpenBOM’s collaborative workspace is a flexible and structured item data model that serves as the foundation for managing all product-related information.

Key Features of Item Records in OpenBOM

- Classification & Types – Items can be classified into different categories (e.g., mechanical, electrical, software, raw materials, fasteners, etc.), enabling standardization and efficient searchability.

- Structured Attributes – Each item type comes with a customizable attribute set, supporting flexible metadata management (e.g., part number, material, supplier, cost, specifications, etc.).

- File Attachments – Supports CAD files, PDFs, drawings, specifications, and any other digital artifacts associated with an item.

- Links to External Sources – Items can be linked to external repositories (e.g., PLM, ERP, supplier databases, or web services), creating a seamless data ecosystem.

- Instance Attributes – Allows different configurations and instances of an item within different product structures, improving granularity and control.

By organizing items in a graph-based structure, OpenBOM enables scalability, easy integration, and cross-disciplinary data sharing.

Here is an example of how to create a simple catalog in OpenBOM. Everything starts from a simple record and then grows.

2. Product Structure (BOM) & Multi-Disciplinary Knowledge

A Bill of Materials (BOM) is more than just a parts list—it’s a structured representation of product hierarchy, defining relationships between components, assemblies, and subassemblies. OpenBOM supports flexible and advanced product structures ( BOM) management by incorporating multi-disciplinary product knowledge across mechanical, electrical, software, process, and any other domains.

Key Features of OpenBOM’s Product Structure Management

- Hierarchical Product Representation – Supports nested structures with parent-child relationships, enabling a clear top-down visualization of assemblies and subassemblies.

- Support for Various Item Types – OpenBOM allows different item categories (hardware, electronics, software, documentation, tooling, etc.) to coexist within the same product hierarchy.

- Object and Instance Attributes – Distinguishes generic item properties from instance-specific data (e.g., serial numbers, configuration settings, assembly variations).

- Multi-Disciplinary BOM Integration – Engineers can manage mechanical, electronic, software, and process-related data in one unified structure.

- Graph-Based Relationships – Enables linking of alternative parts, substitutes, suppliers, and other dependencies for better supply chain visibility. These models can be developed using advanced data management capabilities – custom objects, object references (typed links), and generic references.

This approach ensures that product structures remain consistent, adaptable, and traceable across different disciplines.

Here is a video with a flexible multi-disciplinary product structure:

3. xBOM and Lifecycle – Managing the Full Product Lifecycle

Beyond traditional generic product structure BOM management, OpenBOM introduces xBOM, a flexible approach that supports multiple BOM structures across the product lifecycle:

xBOM – A Unified Approach to Lifecycle BOMs

- Engineering BOM (EBOM) – Defines the product structure as designed, containing components, CAD references, and design-related metadata.

- Manufacturing BOM (MBOM) – Represents how the product will be assembled, including manufacturing processes, operations, and work instructions.

- Service & Maintenance BOM (SBOM) – Includes spare parts, maintenance schedules, and repair documentation, as well as supporting aftermarket services.

- Procurement BOM – Organizes data for purchasing, vendor selection, and supply chain coordination.

Watch some examples of how multiple BOM Types can be added:

Lifecycle Management & Change Control

- Revision Control & Item History – Tracks changes across item records, ensuring full traceability of design modifications.

- Change Management Workflows – Supports review and approval processes before BOM changes are finalized and propagated.

- BOM Compare & Change Analysis – Users can compare BOM revisions, highlighting changes and understanding their impact.

- Interconnected Data for Digital Thread – Links various BOM types and product lifecycle phases, enabling a connected digital thread.

By creating unique data management BOM capabilities, OpenBOM’s xBOM service ensures a seamless flow of product data across engineering, manufacturing, and service domains.

Check the full scenario of multi-disciplinary product structure captured from multiple systems managing revisions and approvals.

Conclusion: The Power of OpenBOM’s Collaborative Product Knowledge Graph

At its core, OpenBOM’s collaborative workspace is built on a product knowledge graph—a flexible, scalable, and interconnected data model designed to manage complex product information across different disciplines, structures, and lifecycle stages.

Key Takeaways:

✔ Item records provide structured, flexible, and interlinked product data

✔ Generic product structures (BOM) enable hierarchical and multi-disciplinary data representation

✔ xBOM and lifecycle support manage multiple BOM views across different phases of the product lifecycle

✔ Graph-based, multi-tenant architecture ensures scalability, data consistency, and real-time collaboration

With modern database technologies, OpenBOM delivers a truly connected, collaborative, and scalable product data management system for engineering, manufacturing, and supply chain teams.

🚀 Coming Up Next: In Part 3, we will explore collaborative user experience, flexible data model, and role-based view access demonstrating how OpenBOM enables real-time collaboration and seamless data management iteration. Stay tuned!

Want to learn more about OpenBOM? REGISTER FOR FREE and start your journey now. Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.