Manufacturing is evolving, introducing new challenges in data management far beyond what we’ve seen before. These challenges include managing the increasing complexity of products—spanning mechanical, electrical, and software components—as well as covering multiple lifecycle stages (requirements, engineering, manufacturing, support, etc).

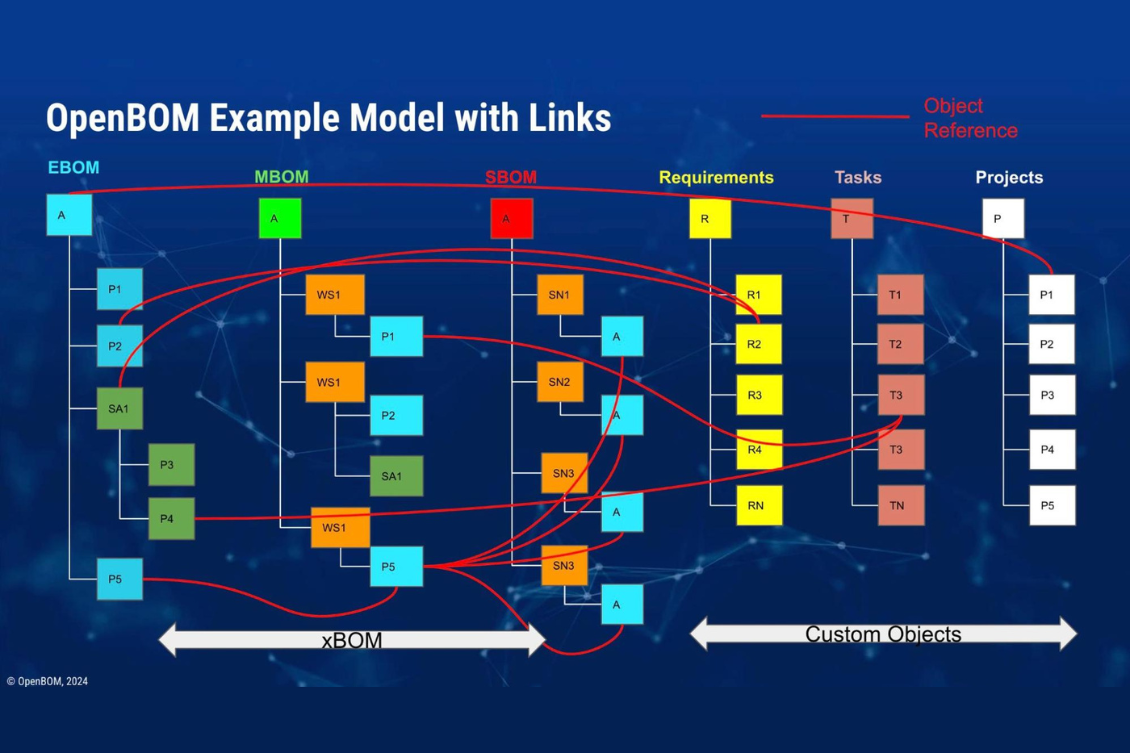

OpenBOM’s vision is to build a scalable, graph-driven foundation that creates a product knowledge graph. This approach offers unique capabilities for developing a flexible and fully customizable product model, capable of reflecting the full complexity of product modeling and processes

OpenBOM’s latest link mechanism is designed to support you with a unique way to connect and organize data. With our new object reference properties, you can seamlessly link a wide range of internal and external data, building a true digital thread for your product’s entire lifecycle.

In this blog, we’ll show you the first demo of how to use this powerful new feature to build data objects and links. The demo walks through a practical example, highlighting how to create custom connections between various objects—including tasks, CAD files, vendors, orders, and purchase orders (POs).

How OpenBOM’s New Link Mechanism Works

The foundation of the link mechanism is a new object reference property. These properties allow users to define connections between various objects. Whether it’s linking CAD files to tasks, associating items with vendors, or connecting orders to POs, the link mechanism gives you full control over how your data is related.

This is an example of how you can get full flexibility in creating a dynamic digital thread. The object reference properties allow you to create both simple and complex relationships, ensuring that you have a tailored view of your product data that fits your specific needs.

Combined with other data model properties and external links OpenBOM data models allow the creation of semantic relationships as well as links to a variety of external systems.

Creating a New Object Reference

You can see an example of creating a new object reference. Here’s a quick overview of the steps demonstrated:

- Create a new property. Select the name and choose it as an object reference. You can create a link property in place (just by adding it to existing objects) or you can use a property table to create a new property.

- Define the Object Reference Properties: Use OpenBOM’s interface to specify the type of link you want to create. You can define what object it connects to and what will be the display value to be used to create a link itself.

- Create the Link: Complete the linking process by specifying which objects you want to connect to. The demo shows how easy it is to establish a connection between different data types, like linking a task to multiple CAD files or connecting a single order to multiple POs.

From the demo, you can see how simple it is to create link properties and create the links in real-time. It makes it easy for users to start building connections without needing extensive training (spoiler- we are going to introduce a special REST API that will allow you to build links).

Building Custom Objects and Connections: Examples from the Demo

OpenBOM’s new link mechanism especially shines with its ability to handle complex relationships. You can see several practical examples that illustrate how to build custom objects and connections, showcasing how versatile the platform is when managing diverse product data:

- Tasks Connected to Configured Items

In this example, a task is linked to a configured item (defined in one of the item catalogs), such as a product assembly, sub-assembly or part. This connection ensures that any updates to the item are reflected in the task, enabling traceability throughout the design and production phases. - Linking Tasks to CAD Files

The demo illustrates how you can link a single task to multiple CAD files. This setup is ideal for managing projects where a task involves several design objects defined in OpenBOM, iterations, or when coordinating efforts across different engineering teams. The object reference properties make it easy to trace which CAD files are associated with which tasks. - Connecting Vendors and Orders

Another example in the video shows how to create links between vendors and orders. By connecting items to vendor data, you gain a clear overview of who supplies which components, improving procurement accuracy and streamlining supply chain management. - Integrating Orders and POs

The video demonstrates how to link multiple POs to a single order, offering a consolidated view of procurement activities. This multi-object linkage helps teams keep track of various parts ordered, manage inventory, and ensure that production timelines stay on schedule.

Building a Digital Thread Across Multiple Objects

The flexibility to connect one object to many others is a significant advantage of OpenBOM’s enhanced linking system. For example, a single task can be associated with several CAD files, orders, vendors, and more, creating a detailed web of interconnected data. This multi-object connectivity provides a richer view of your data, fostering collaboration across departments and keeping everyone aligned.

Watch the Video Demo

Ready to see it in action? Watch the full demo video to explore OpenBOM’s new link mechanism and discover how it can transform the way you manage product data:

Conclusion and Why OpenBOM’s Link Mechanism Matters

This enhanced link mechanism is a significant upgrade for managing complex product data. It’s not just about creating simple associations; it’s about building a comprehensive digital thread that adapts as your product evolves. Here are a few reasons why it’s so impactful:

- Better Traceability: Every object and connection is traceable, providing full visibility into how your product data interacts and evolves.

- Simplified Integration: With the ability to reference external systems and integrate other services, OpenBOM creates a unified data ecosystem without the complexity of manual data entry.

- Dynamic Updates: As your product data changes, linked connections automatically update, keeping everyone in sync with the latest information.

The demo is a great introduction to the possibilities that OpenBOM’s new linking capabilities offer. If you’re looking to streamline your product lifecycle management and build a resilient digital thread, this tool is designed to make that process simpler, faster, and more intuitive.

Future enhancements in OpenBOM will be focusing on establishing links automatically and using APIs.

Stay tuned for more updates as we continue to enhance OpenBOM, empowering you to create a more connected, agile, and efficient product data environment. Feel free to reach out for a personalized demo or more information on how these features can benefit your organization!

REGISTER FOR FREE to try out our new OpenBOM link mechanism.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.