Bill of Materials is a lifeblood of your manufacturing business. It defines all components and assemblies you need to have to produce a product. To make it happen, the lifeblood needs to flow between places and people in your product development business process. Even if you’re a small manufacturing company or hardware team working on the prototyping of your first product, you need to have a BOM. The value of BOM is to connect information on both sides of the process. Very often it is an engineering team and purchasing. Sometimes, it is the same person or several persons that need to order parts based on what you design.

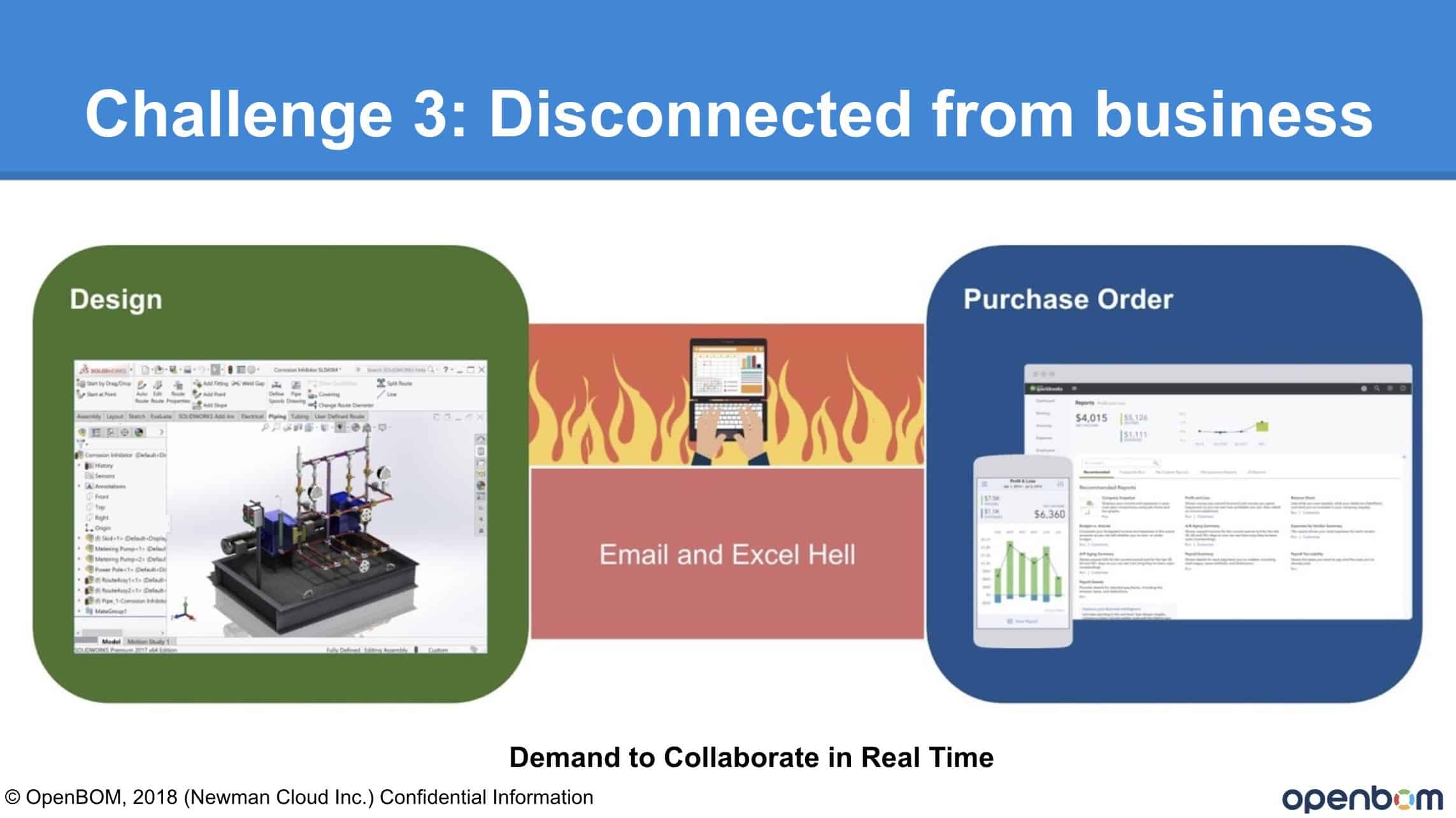

The disconnected process is one of the top 3 challenges in manufacturing digital transformation. Very often, this process looks like this picture below. You have a CAD system (eg. Solidworks) and accounting software you use to order parts (eg. Quickbooks). Between these two places, you have Excel and Email Hell. Literally… Tons of emails with excels are flowing back and forth. Guess what? You will miss something and it will cost you time and money. Because you will have to order parts at the last moment (more expensive) and you will be later (time) in your development.

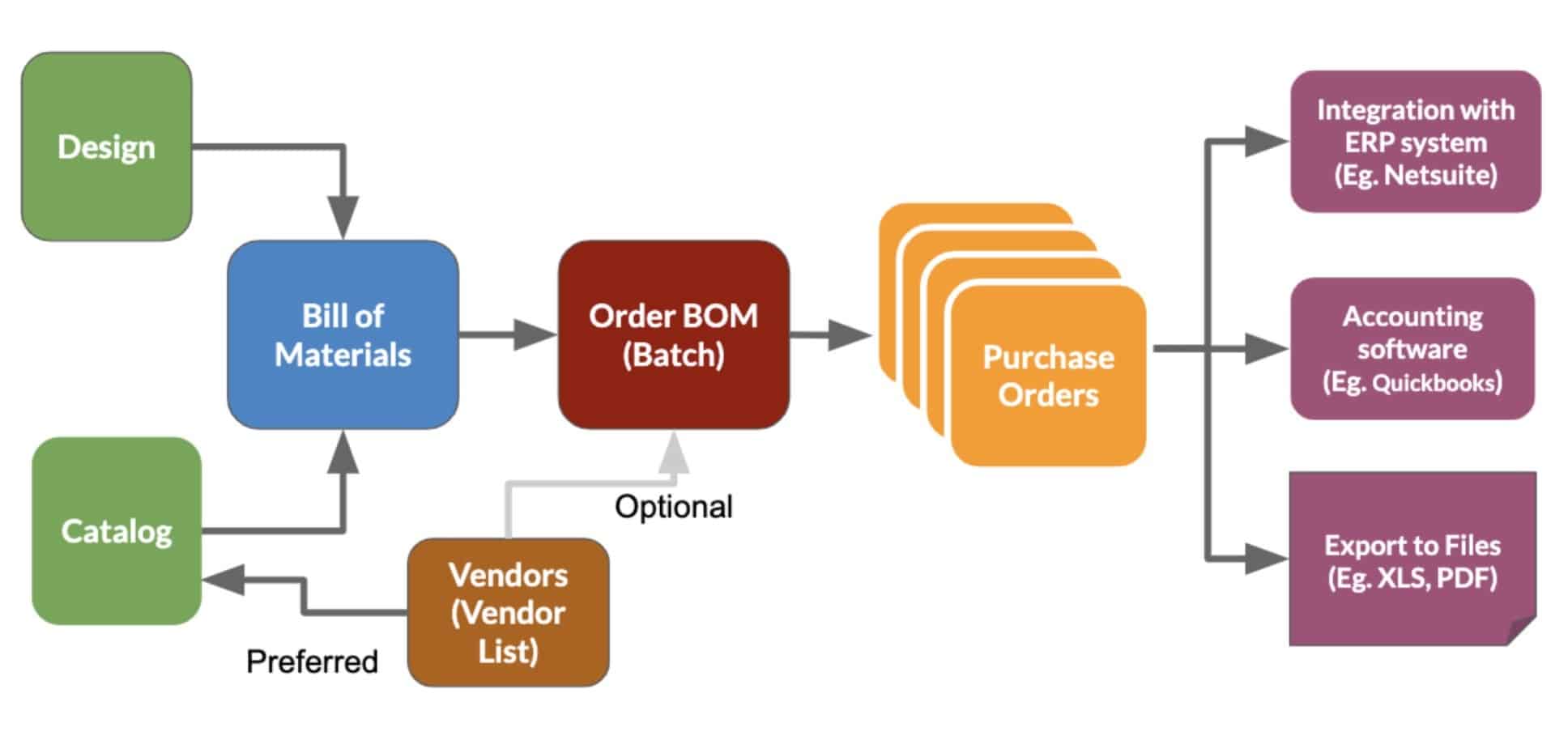

We found it by talking to many of OpenBOM users and later customers. To prevent it to happen, OpenBOM gives you a better way to organize this process and to eliminate Excel and Email hell. The following picture (you probably have seen it before) gives you an idea of Design to Purchasing workflow.

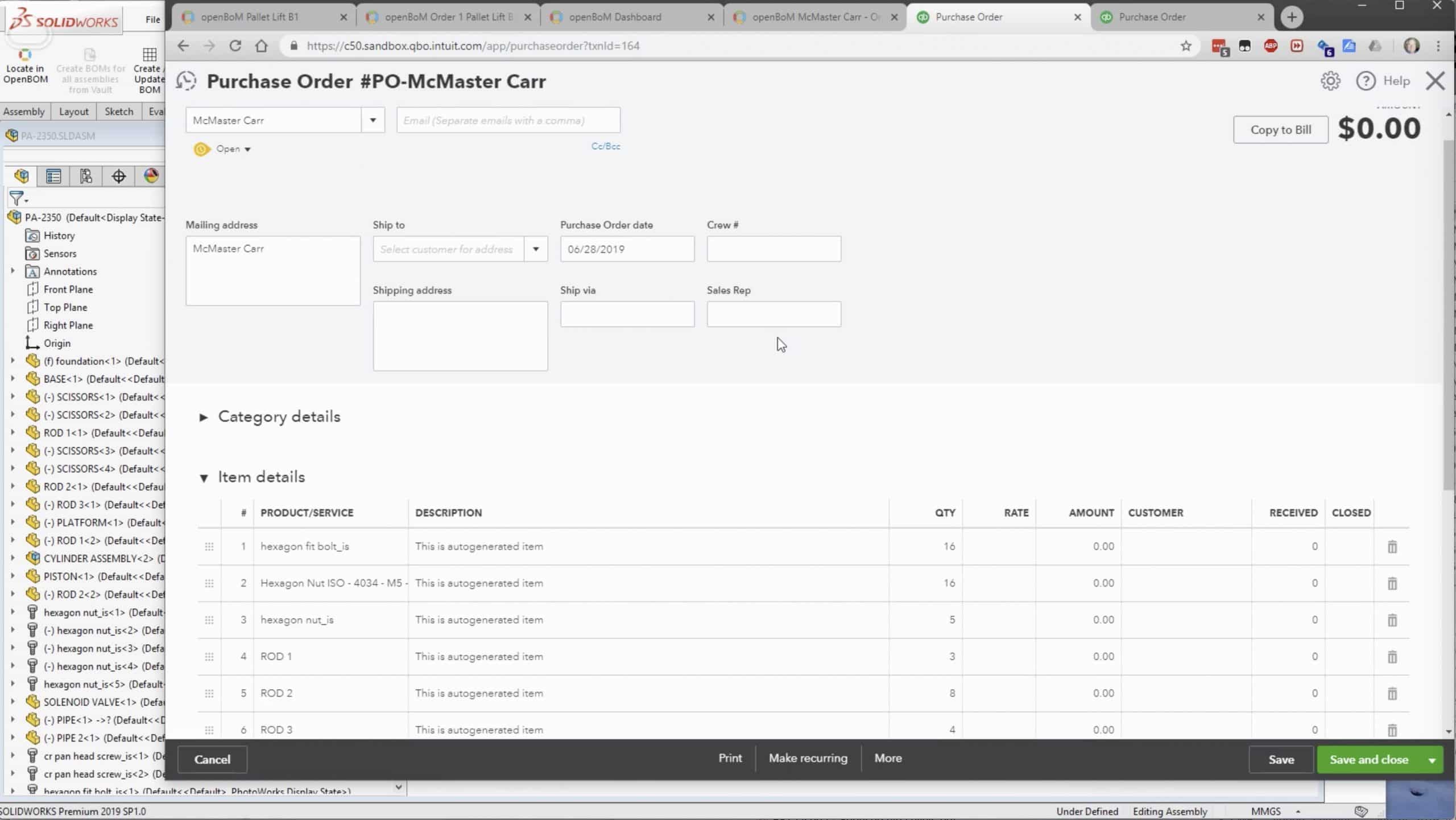

We are about to introduce first OpenBOM integration with accounting software (Quickbooks online). This integration will help you to streamline the process and transfer information automatically between CAD (Solidworks), Bill of Materials (OpenBOM) to Purchase Order (Quickbooks).

Check this video for the first time demonstrating you this end-to-end process.

Conclusion

You probably heard about Digital Transformation. These days, digital technologies are helping to transform processes from analogs (using documents, paper, phone, email) into digital (connected application, information, businesses). OpenBOM Design to Purchase process is an example of how to digitally transform a process of making things from early design to ordering parts. So, everything gets connected. It doesn’t require to replace all tools you use today. OpenBOM is connecting to existing tools and helps you to change the way you organize your business.

Want to discuss how OpenBOM can help you? Contact support@openbom.com. Want to check OpenBOM online? Register for FREE user subscription here.

Best, Oleg

PS. Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.