One of the most critical features in BOM management is the ability to manage multi-level structures (BOM). Think about complex structure of assemblies, sub-assemblies, and parts. When you have hundreds, thousands and more parts, it is very hard to calculate how many parts you need to purchase for a specific machine (eg. Top Level Assembly).

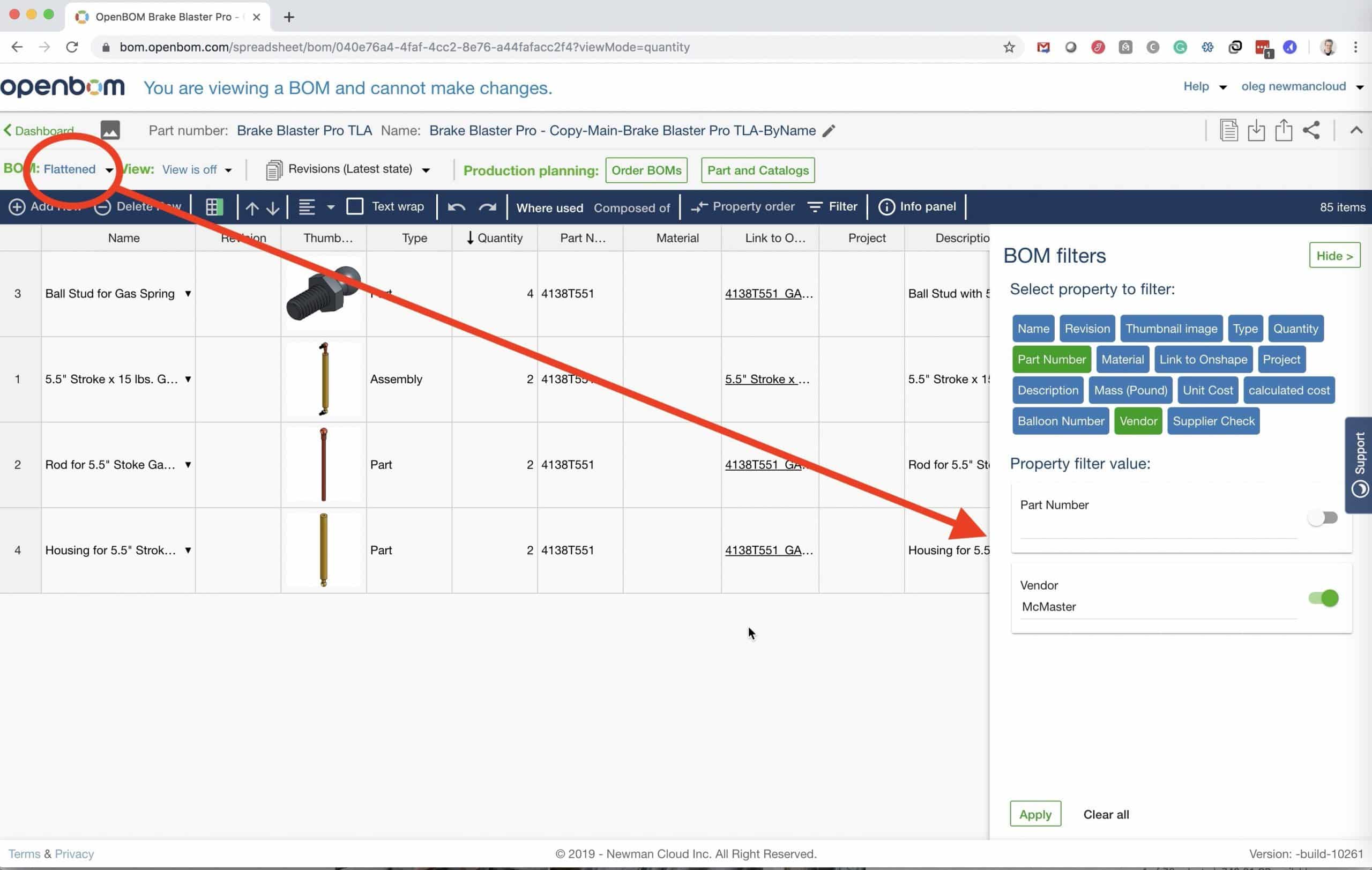

OpenBOM has an easy solution for you. OpenBOM Flattened BOM can instantly turn any multi-level structure imported from the CAD system or created from multiple spreadsheets into Flattened BOM answering on a famous question – how many screws I need to build this machine?

So, it is hard to underestimate the importance of Multi-level and Flattened BOM. For quite some time, OpenBOM Flattened BOM was lack of filtering capabilities. And we’ve got it now 🙂

Since October 6th OpenBOM update, Flattened BOM filter is included in OpenBOM functionality.

I recorded a very short video demonstrating how it can be used.

To filter in flattened BOM is easy – just switch to flattened BOM and go to the filter menu. It is important to remember that all other functions of OpenBOM and especially export from flattened BOM can be used together with filters.

Conclusion

Flattened BOM is an easy way to create a summary of all parts and assemblies you need to the manufacturer to the top-level product. Adding filter capabilities will improve the way information from OpenBOM can be utilized downstream for purchasing and manufacturing planning.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.