Every manufacturing company is buying parts and outsource some work to contractors and suppliers. Although the process is pretty straightforward, it is not as simple as it might sound. Let’s be honest, the procurement doesn’t sound fancy as a design process, but if it is not done, your shop, team, or company will be delaying shipment or spending much more money on urgent and late orders.

In my article today, I want to share a recording of the OpenBOM webinar in which we present the OpenBOM purchasing workflow. From our experience of working with customers, such a workflow very typically helps to organize production in various ways for batch manufacturing, prototyping, custom machinery, food processing, and many other similar scenarios where you don’t need to build a large scale production lines. The last one will belong to ERP implementations and in this case, OpenBOM gives you a variety of options from ready to use integrations (eg. OpenBOM On Suite App Store) and also solutions to use OpenBOM export/import or development using OpenBOM REST API.

Here is the video from the recent webinar – Design Through Purchase.

And here is the slide deck

Conclusion

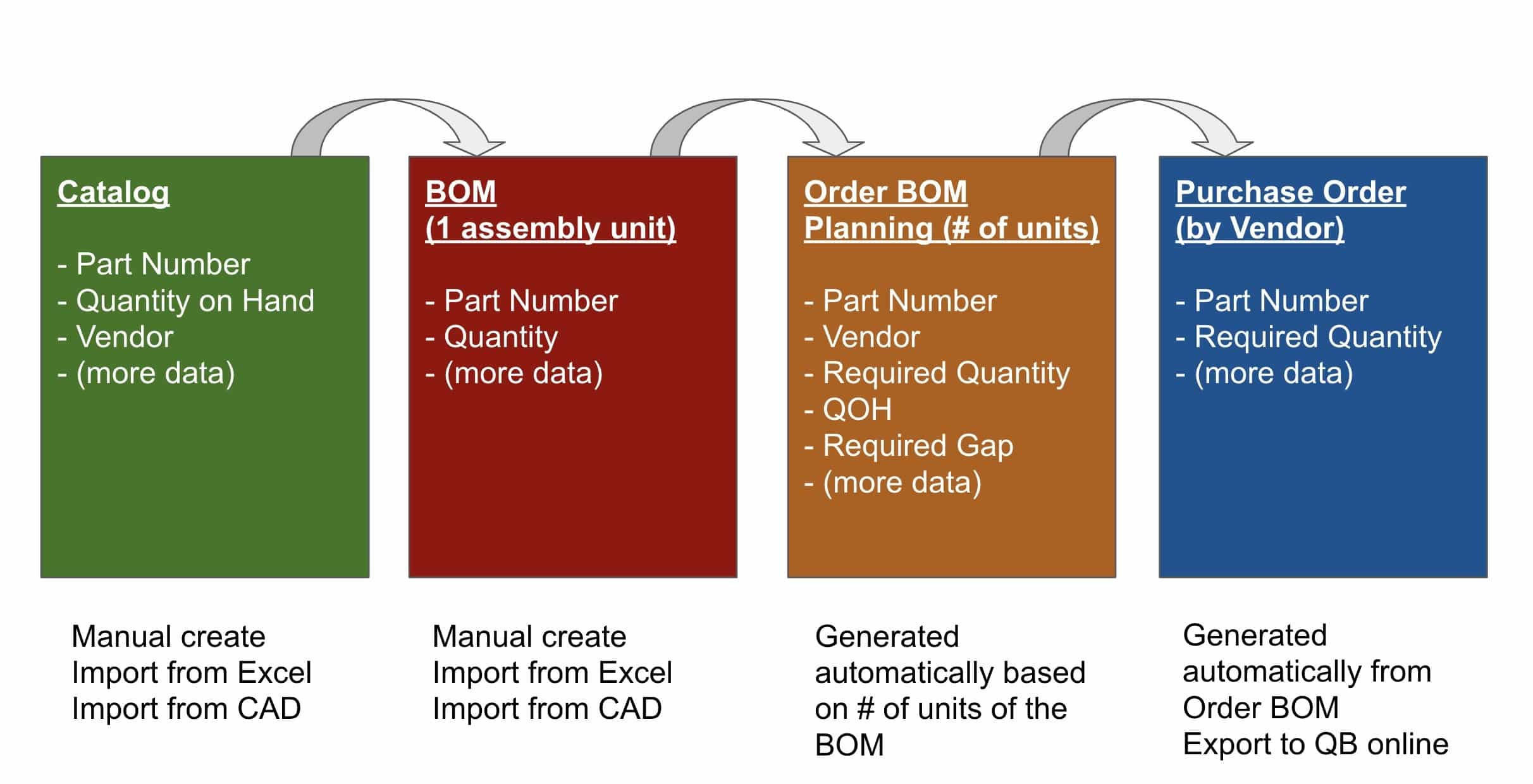

OpenBOM allows you to put a BOM and product data in the foundation of the purchasing process. It brings many benefits by allowing you to know exactly what do you need to build a product, when do you need it, who will deliver it, and when. Without such a foundation, your procurement team is working blind out of guesswork. To change it and make it data-driven and efficient is the main goal we aim with the OpenBOM purchasing process.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.