In today’s fast-paced manufacturing landscape, the journey from a CAD design to the first product release is more complex than ever. Companies must balance speed, accuracy, and collaboration while ensuring their design and manufacturing data remain aligned.

In my previous article, we spoke about 5 characteristics of Digital BOM you can manage in OpenBOM. The Digital BOM is a foundation of the OpenBOM Product Knowledge Graph. In my article today, I want to walk you through the steps of moving from CAD design to Engineering Release. You will see how OpenBOM works in the real process.

This blog explores how integrated CAD systems and digital BOM management can streamline this journey and help teams achieve a successful product release.

The Foundation: CAD Collaboration as the First Step

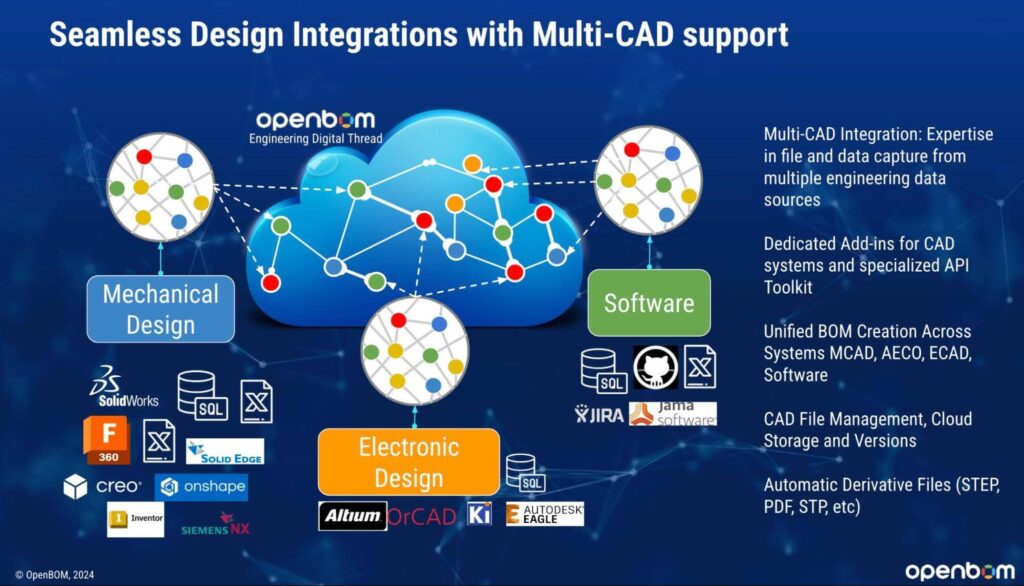

Every successful product starts with collaboration. In the design phase, CAD collaboration is crucial for bringing together ideas, expertise, and feedback. OpenBOM Design Projects allow engineers to work together ensuring everyone in the multi-disciplinary team of engineers working on mechanical, electronics, and software design can work together.

The first step is bringing CAD files (eg. SOLIDWORKS) to the OpenBOM cloud storage allowing seamless collaboration and file management. The distributed team can get access to each file while maintaining the integrity of the data and access control. For example, a change made by one team member is instantly visible to others, ensuring that the design evolves cohesively. Seamless integration with CAD tools supports notification and locks preventing engineers from overriding each other’s work. Autodesk 3D Viewer integrated using the open viewer architecture of OpenBOM is an example of cloud components working seamlessly together.

This collaborative groundwork is vital for transitioning into the next phase: integrating CAD data with the BOM system.

The Challenge of Transitioning From Design to Release

For many companies, the transition from design to manufacturing is fraught with challenges. CAD data often exists in isolation, requiring manual updates to BOMs, which can lead to errors, miscommunications, and delays. Excel, emails, and other homegrown methods create a lot of siloes and data inefficiency. Furthermore, as designs change, outdated BOMs may inadvertently be used in procurement or production, causing costly rework.

These issues stem from the lack of integration between CAD systems and BOM management tools. Without a unified approach, teams struggle to maintain consistency across their design and manufacturing processes, resulting in inefficiencies that hinder product release timelines.

OpenBOM’s seamless ‘One-Click BOM’ allows you to capture information from multiple CAD systems and other data sources.

The Role of Integrated CAD and Digital BOM Management

Integration is the key to solving these challenges. By linking CAD systems with digital BOM management tools, teams can create a seamless flow of data from design to release. Any changes made in the CAD environment are automatically reflected in the BOM, ensuring that all stakeholders have access to the most accurate and up-to-date information.

Digital BOM management also introduces several powerful advantages:

- Real-Time Updates: Teams can see changes as they happen, reducing delays and confusion.

- Multi-View BOMs: Different departments can access BOM representations tailored to their needs, such as EBOM for engineering or MBOM for manufacturing.

- Revision Control: Integrated systems track revisions, ensuring traceability and compliance throughout the product lifecycle.

This integration not only streamlines the process but also lays the foundation for a successful product release.

Capturing the Digital BOM

Transitioning to a digital BOM is more than just replacing spreadsheets; it’s about creating a dynamic, interconnected data model. A digital BOM serves as the single source of truth, connecting engineering, procurement, and manufacturing teams.

By capturing a digital BOM, companies can:

- Eliminate manual errors that occur with spreadsheet-based BOMs.

- Enable traceability by linking components to their sources, specifications, and associated documentation.

- Adapt quickly to design changes, ensuring that the entire team stays aligned.

The digital BOM becomes the backbone of the design-to-release process, enabling smoother collaboration and faster decision-making.

Initial Product Release: Turning Designs Into Reality

The product release phase is where designs meet reality. It involves finalizing the BOM, securing approvals, and ensuring the product configuration is ready for manufacturing and procurement. Integrated CAD and BOM systems simplify this process by providing:

- A clear workflow for approvals and revisions.

- Automatic updates to BOMs based on CAD changes, reducing last-minute surprises.

- Insights into component availability, costs, and sourcing options.

With a streamlined release process, teams can focus on bringing their product to market faster and with greater confidence. By connecting CAD and BOM data, they ensure that the right product reaches the right stakeholders at the right time.

See It in Action: Video Demo

To truly understand the power of integrated CAD and BOM systems, seeing them in action makes all the difference.

In this demo video, we’ll showcase:

- How to manage CAD files seamlessly using Design Project

- How to set up a seamless connection between CAD and BOM tools.

- Real-time updates as design changes propagate to the BOM.

- Initial Digital BOM release

The video provides a step-by-step walkthrough of how these systems work together to simplify your design-to-release process. Watch as we demonstrate the power of digital collaboration and integration in action.

Conclusion

The journey from CAD design to product release is complex, but it doesn’t have to be chaotic. By prioritizing collaboration, integrating CAD and BOM systems, and embracing digital BOM management, companies can streamline their workflows, reduce errors, and accelerate their time to market.

If you’re a small manufacturing company working on a new product or design team in a large enterprise, the right tools can make all the difference. Ready to transform your product development process? Explore how OpenBOM can help you build a seamless connection between CAD and BOM today.

REGISTER FOR FREE and check OpenBOM today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.