In the realm of Computer-Aided Design (3D CAD) and data management systems and data management tools such as PDM and PLM the landscape is constantly evolving. As the world becomes increasingly digital, the ways in which industries harness and utilize data for streamlined operations are also undergoing a sea of change. It was a time when the industry discussion was solely focused on the export of CAD files in a neutral format. Later, the technology moved towards integrated functions. Now, we are moving into a new phase of digital transformation that demands new types of functions for engineers to work. Let’s talk about the journey from traditional CAD integrations to the emergence of design data services in detail.

The Imperative Nature of Data Integration

Data is often termed as the ‘new oil’ of the 21st century. However, the true value of data isn’t in its mere existence, but in how it’s integrated, processed, and acted upon. Businesses today grapple with proprietary files that act as barriers to seamless data flow. This lack of interoperability not only hampers efficient operations but also creates hurdles in cross-functional collaborations. Therefore, there’s a pressing need for solutions that can bridge these gaps, facilitating smooth data integration.

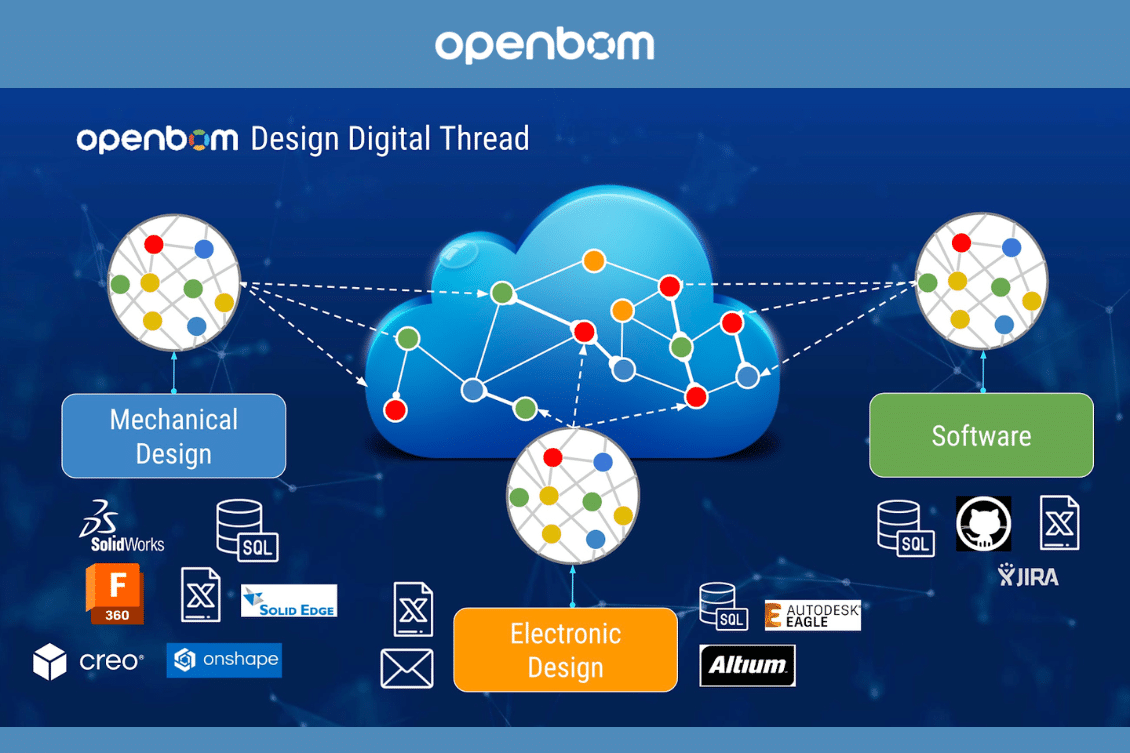

The picture below can give you an idea of how complex product data management systems are and the modern landscape of manufacturing companies and communication.

There is a need to bring modern database management systems to improve data quality management and help the manufacturing industry to improve the manufacturing process.

Legacy Methods: CAD Add-ins

Historically, the Product Data Management (PDM) and Product Lifecycle Management (PLM) industries leaned on CAD add-ins to bridge the integration chasm. While these add-ins played a pivotal role in integrating diverse data sources with CAD systems, they presented their own set of challenges. The constant cycle of installing, updating, and ensuring compatibility with each successive CAD system release meant that businesses were often caught in a loop of maintenance, detracting from the core purpose of innovation and design.

From the very first days of OpenBOM, we focused on how to integrate OpenBOM to capture CAD data. Here is an example of a typical OpenBOM CAD add-in with SolidWorks.

Cloud-Driven Modernization of CAD

Change is the only constant, and the CAD industry is no exception. Modern CAD software solutions are embracing the capabilities offered by cloud technologies, heralding a new era of integration and collaboration. Platforms such as Onshape exemplify this shift by offering data through REST API. Industry titans like Autodesk are also not far behind, pivoting their strategic focus towards data access APIs, highlighting the significance of data-centric platforms in today’s design landscape.

Here is an example of OpenBOM Integration with Onshape using REST API.

And here is an example of OpenBOM integration with Autodesk Fusion 360

These shifts represent more than just technological advancements; they signify a paradigm shift in how businesses view and handle design data.

Digital Transformation and the Need for Agility

The term ‘digital transformation’ is more than just a buzzword. It embodies a broader strategic approach where businesses leverage technology to enhance processes, improve customer experiences, and drive innovation. In this context, it’s no longer sufficient for companies to relay data through cumbersome means like Excel sheets. What’s needed is agility—seamless data flow using online services, fostering real-time collaboration, and accelerating decision-making processes.

OpenBOM’s New Design Service Dashboard: A Paradigm Shift

Addressing these emerging needs, OpenBOM’s innovative Design Service Dashboard is a game-changer. This platform isn’t merely a data aggregator; it’s a nexus that connects a myriad of data services. By drawing from diverse CAD systems (MCAD, ECAD), software tools (JIRA), and cloud storage mechanisms, OpenBOM stands as a linchpin of data transformation. It meticulously processes this vast amount of data, churning out actionable insights that become the bedrock of strategic decisions, spanning from procurement strategies to nuanced product development.

OpenBOM Introduces a New Design Dashboard that allows you to integrate multiple design data sources.

The coming release introduces a connection to Autodesk Manufacturing Data (MFG) Data model.

Also, from the same dashboard, you can get to AECBOM connecting to Autodesk Revit Data for takeoff service.

Check out more about Autodesk Data APIs in my article – What I learned at Autodesk Dev Con.

Conclusion

The journey from traditional CAD integrations to cutting-edge design data services underscores a broader narrative of evolution and progress. A typical data management process is transforming and traditional database management systems are replaced with modern data management platforms to stream data integration to support modern and agile manufacturing processes.

As businesses seek enhanced agility and data-driven decision-making capabilities, platforms like OpenBOM’s New Design Services Dashboard are not just tools; they are catalysts for transformative change. By centralizing and streamlining design data access, they are reshaping the very fabric of product development, heralding a future where data isn’t just accessed, but truly harnessed.

REGISTER FOR FREE and start a free 14-day trial to learn more.

Learn more about OpenBOM Design Projects– a free service coming to provide simple data storage and revision control for CAD files.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.