Manufacturing is evolving. With the advent of cloud-based technologies and manufacturing networks, the industry is changing faster than ever before. Excel sheets and standalone systems are becoming a thing of the past. In this blog post, we’ll explore the changes that are taking place in manufacturing and discuss how businesses can take advantage of them. We’ll also look at some of the challenges that manufacturers face today and how they can overcome them. So, if you’re interested in learning more about the future of manufacturing, read on!

Spreadsheets – Best Sofware For Everything?

The history of engineering, manufacturing and other business software such as PDM, PLM, and ERP is full of Excelware. Working with many customers for the last 20 years, I always knew that any manufacturing company even if they use some of the software I mentioned above, always has some “excels” hidden aside that they use (because X software just cannot do what we need). This is happening with large OEMs and enterprises. The situation is awful with small and medium-sized companies. Excel is the second-best software for everything and engineers, production planners, procurement personnel are using them to get things done because other things are just way too expensive, way too complex, and just not flexible to do what they need.

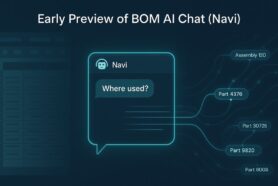

There are so many examples of tasks that are crazy complex and take hours of Excel work and even after that lead to mistakes and requires expensive overdue. My best example is how to calculate the total quantities of a specific part in multiple assemblies. Think about having 5 Excel files and combining them to calculate totals. The work can take hours. Think about a user that needs to have a system to run a query about where a particular part is used to make a change. Another example is cost rollup. I’m not talking about situations when you need to refer to a previous revision of the data. These things are just impossible to do, but the reality of manufacturing processes is that you need to perform them every day.

Cloud Services and Death of IT

Old business software (PDM, PLM, ERP) was expensive and requires IT people to install, configure, and maintain. Therefore large companies paid a fortune to have them implemented and then use them without many alternatives. Until SaaS and cloud software was born out of the magic of web and internet development. IaaS companies and private hosting providers can give you virtually any infrastructure to run your systems and access them from any device. It was a time change started to happen and business software have started to migrate to the cloud. They are much easier, no installation required, and much simpler – these systems are making their steps in manufacturing these days. Recent research by CIMdata – a leading consulting and analytical company says that 66% of all manufacturing companies are looking at how to replace their legacy software with new cloud systems. The same goes for Excels. Why create Excel manually and share it via email, when you can register for OpenBOM in 5 minutes, set up CAD add-in, and start managing BOM and production planning in minutes. Read hundreds of reviews and customer stories about how OpenBOM software helped engineers and companies to start managing data and create a single source of records for product information.

Networks – Connected Factories and Supply Chain

The most interesting is the next step that will happen after companies migrate to cloud software and SaaS applications – these systems will start connecting together. The development of cloud technologies, connected service, and new manufacturing technologies open the doors for innovation to have online services that can be used by a variety of players in manufacturing – OEMs, suppliers, equipment manufacturers as well as new players providing online services. I brought a few examples of such services in my article From PLM to Manufacturing Networks. Check it out and learn how connected services will turn manufacturing companies into connected factories, establish an agile supply chain and prevent bottlenecks and fire drills needed to deliver products on time and within cost. “Data” will become a great enabler of businesses and systems in the 21st century. Back hundreds of years ago, manufacturers were looking at how to stay near the banks of the rivers to have access to power and other resources. In the last century, companies that had access to oil were extremely powerful. Nowadays, “data” is king and will allow manufacturing companies and other businesses to rule the world.

Conclusion

Are you still using Microsoft Excel to manage product information, gather part lists, retrieve data into an excel spreadsheet, and request an excel file from multiple users supplies, and contractors? Too bad. It means that you don’t have a reliable way to manage data, your data integrity is at risk, the way you create reports is outdated, you’re the single point of failure in your organization and other users are at high risk of using outdated data. Your order management can be compromised by the wrong information, you don’t know how to find the latest version of your BOM and you have tons of hidden data in Excels that are never exposed for the decision-making process.

The last decade allowed industries to explore cloud software and SaaS applications to reduce the need in local IT to install applications, configure PDM, PLM, and ERP systems across multiple departments and organizations. Cloud and SaaS businesses are thriving and helping to transform industries to be more efficient and organized. To switch from Excel workbook and Excel process to online applications available in the browser to create data seamlessly from design applications, collect information on demand from multiple sources, add customer information and run your business in a more optimal way – this is a trend we can see now. 66% of manufacturing companies are looking at how to replace their old legacy software and Excel files with modern cloud – SaaS applications.

But this is just the beginning. SaaS and cloud software create a foundation for intelligent collaboration and coordination between OEMs, contractors, and suppliers. You cannot achieve it by using Excel. The data is lost in Excel processes, which is damaging decision-making, makes production planning inefficient, and is disconnected from real-time operations. Connecting companies and provider user access to live and updating information is the next step. At OpenBOM, our customers are leaving excel behind and switching to automated and real-time data collaboration using OpenBOM’s patented collaboration method allowing us to share data and improve business decisions. OpenBOM formulas allow performing calculations and getting cost analysis done in real-time. OpenBOM web tools allow seamlessly import data and transform it into actionable information.

Check out how OpenBOM can help you – REGISTER FOR FREE and start a 14-day trial to discover how to switch from outdated Excels to a new modern way of managing your business.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.