OpenBOM data management gives you a lot of flexibility. While in general, I see it a very good thing and can give you a lot of value really quick, it can be also confusing sometimes. Today, I want to talk about different ways to manage data in multi-level structures and some rules I recommend you to follow to prevent confusion and mistakes.

1- Part List

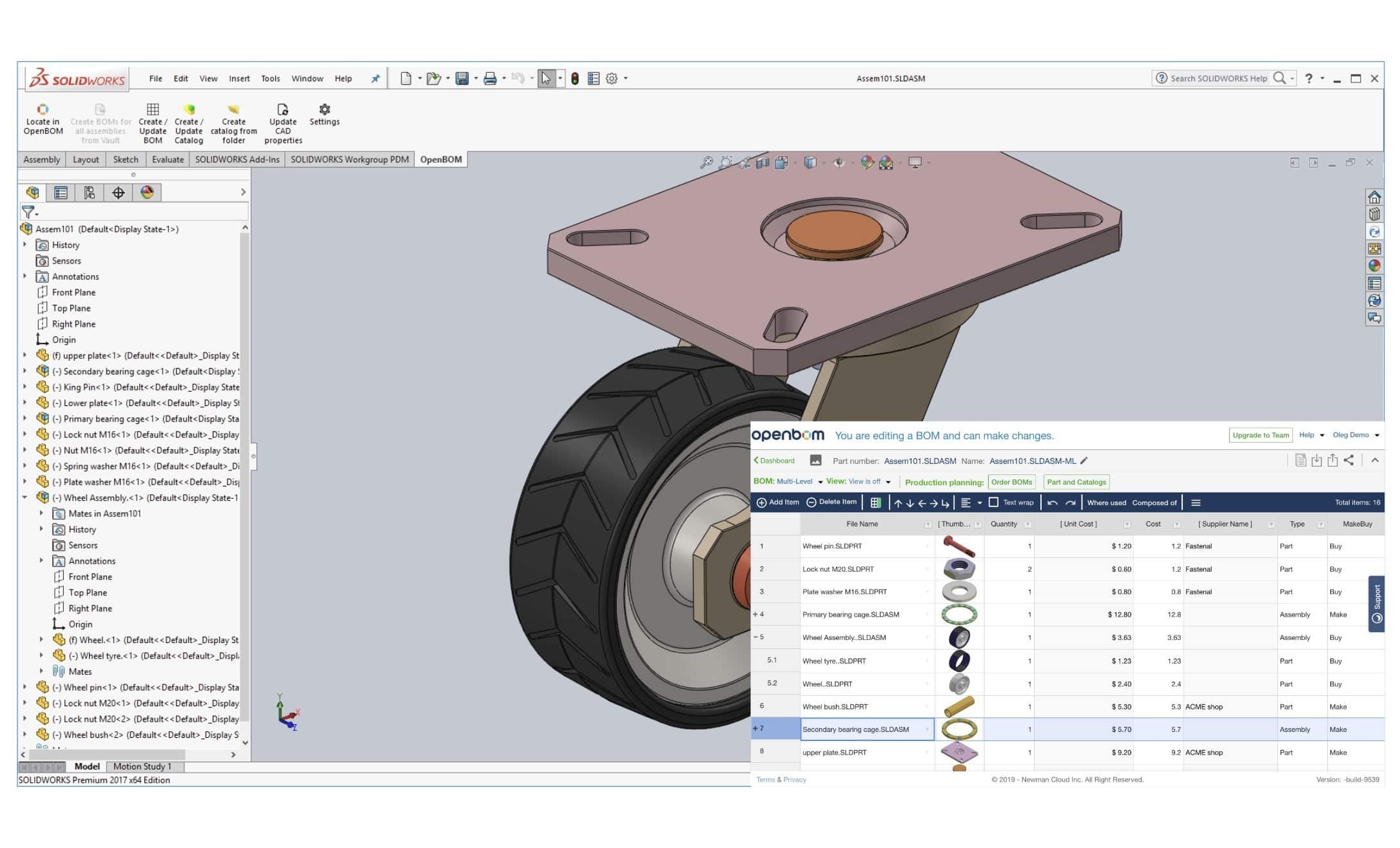

OpenBOM gives you super-fast way to organize part lists and share it with anybody in the world. Combined with free CAD integrations, you cannot go wrong with OpenBOM part list. You can grab any CAD assembly, install OpenBOM plug-in and extract part list. What will happen?

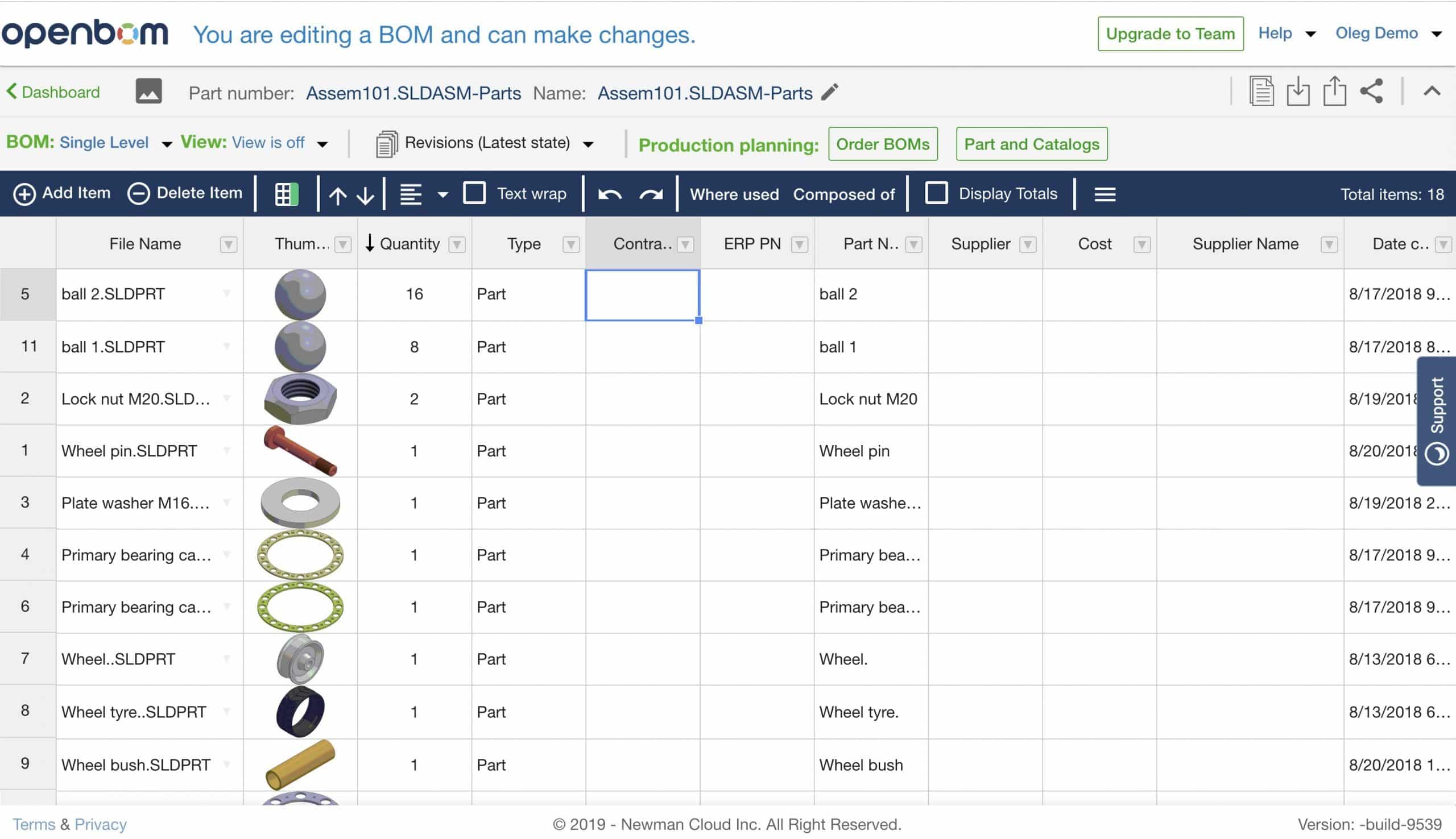

OpenBOM will traverse you CAD structure, calculate quantities of parts and extract a flat list with all quantities. You can have similar functions in any CAD system, but… you won’t able to share it in real-time, add additional attributes and manage baselines. Cool stuff to have it for free. It looks like this one. I’ve made a part list from Solidworks Assembly.

2- Nested Part List (Multi-level BOM).

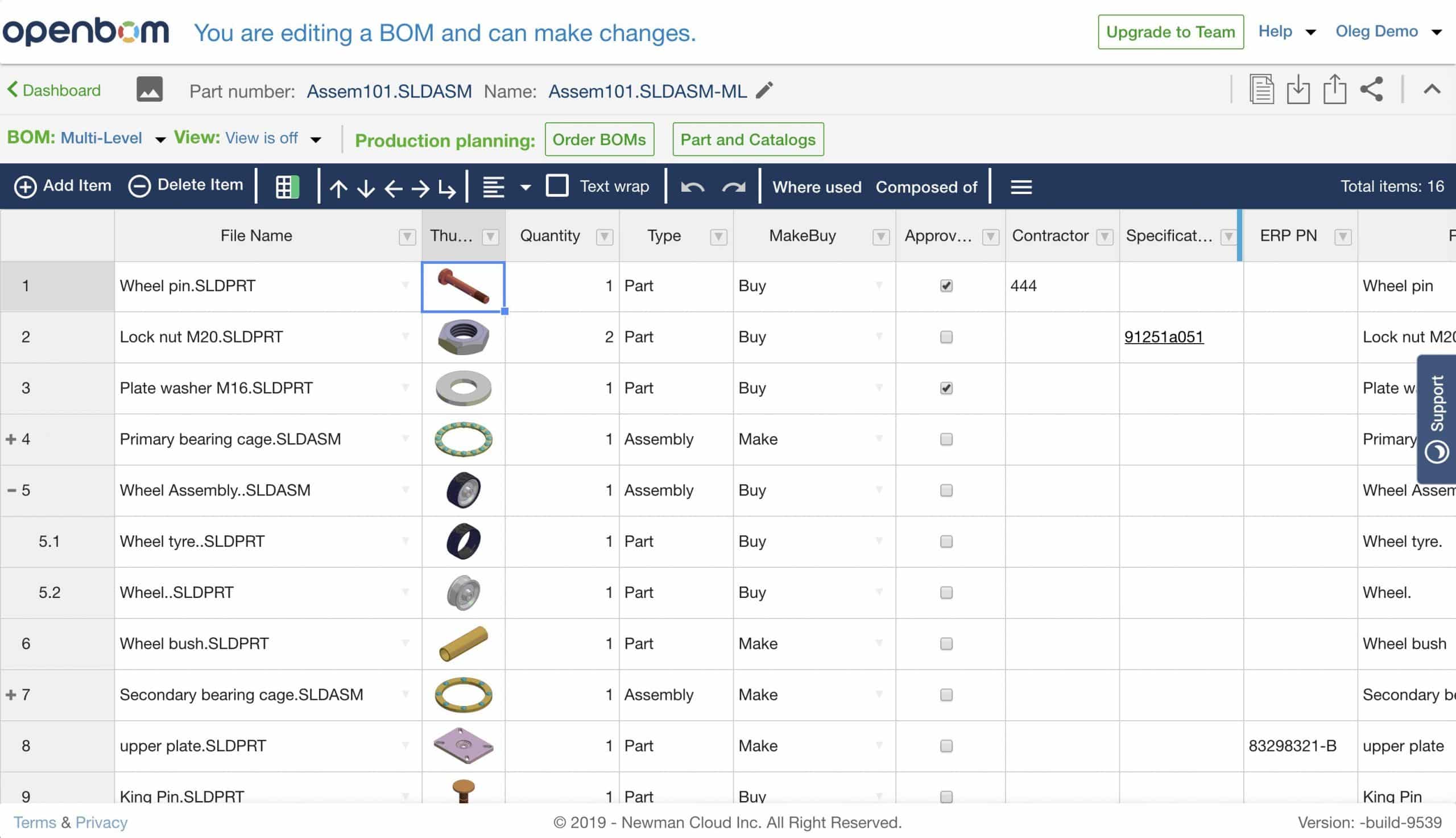

Often you want to manage structured (often called nested BOM). Here is a piece of good news. OpenBOM has an option to generate a multi-level structure from any CAD system automatically. You don’t need to think about anything- click on the button and viola – the nested structure is created.

There is a price for the moment behind this automatic operation. OpenBOM doesn’t care much about items (I will talk about them later). So, what you’ve got is a nested part list. It gives you a lot of good things to do – automatic flattened BOM to calculate quantities, rollups and many others.

But the price you pay is related to the way you will manage OpenBOM catalogs. Or saying it bluntly, you won’t. Which means OpenBOM automatically won’t create catalog items for you and it will create a level redundancy in your BOM (eg. multiple lines for each part, for example, screw, you use in different places).

Here is an example:

Nested multi-level part list is good because how easy you can do it, but can be somewhat limited.

What is next? – True multi-level BOM.

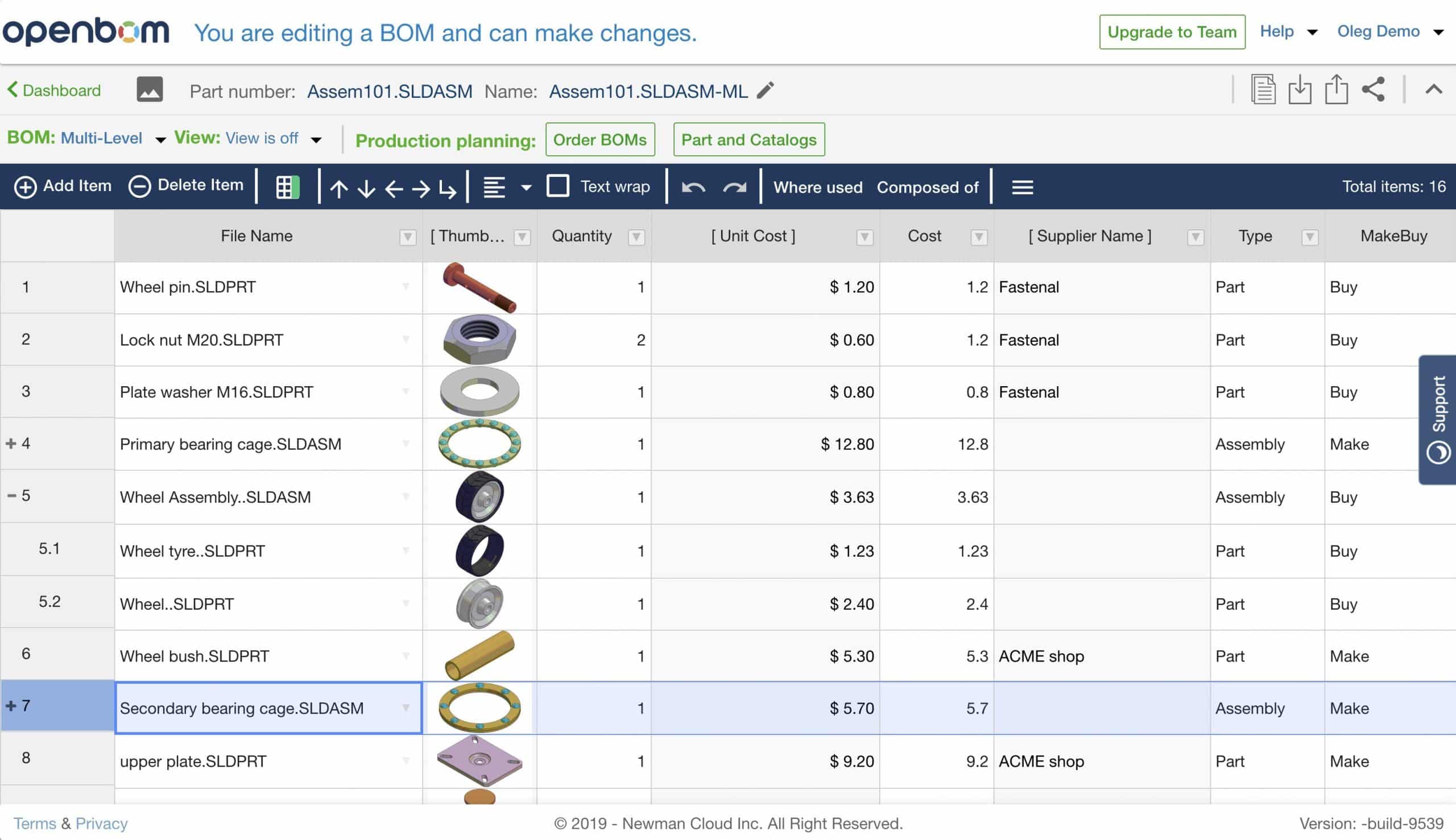

3- Product Structure (Multi-level BOM with Catalog Items)

This is how data is managed in all PLM and ERP systems. You have Item definition in OpenBOM catalog(s) and you instantiate it in OpenBOM Bill of Materials. Check out OpenBOM reference-instance model (). In such a way OpenBOM can manage the most complex data structures.

What is a drawback? When it comes with an additional level of complexity to configure how OpenBOM CAD plug-in is extracting data.

You should first to organize catalog(s) with items- assemblies and parts. You can create them manually, import from Excel or import from CAD system using OpenBOM plug-in. Think about this data as centralized storage of data about all items – standard, fabricated, outsourced.

The second step is to create a BOM. Bill of Materials will instantiate parts and create a structure (multi-level BOM), which will reference a single database of items. Pay attention in the picture below item properties are coming in square brackets. You can edit them in a catalog, but not in a BOM. In such a way, OpenBOM behaves similar to what you expect from any PLM system.

What is coming next? We realized, sometimes these t stages can be too hard for users. So, we are planning to simplify it even more. Later these years, OpenBOM CAD plug-ins will start to modify.

Also, you can learn more about PLM and product development life cycles that will help you get the basics and according to information to go further. You can also get in touch with us, we will be happy to answer all your questions.

Conclusion.

OpenBOM gives you a high level of flexibility in the way you create BOMs – from a simple part list to nested list and fully-fledged product structure with items and BOMs. You have a choice to make how to work. Start simple and move to more complex use cases. If you plan to work with product structure with catalogs and BOMs, please take into account that you need to spend some time to plan it – catalogs, properties, BOM, etc.

Check our blog and YouTube for videos and examples.

Best, Oleg

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.