Digital Transformation is one of the biggest transformational trends these days and companies are actively looking for solutions that can help them establish a digital strategy. For many companies in the manufacturing and construction business, it will be a matter of survival in the next 3-5 years.

If you think I’m joking, please think again. Companies are experiencing growing challenges in their ongoing operation and new product development. Many factors are impacting the way companies work – product complexity, development speed, growing cost, challenging workforce, compromised, and challenging supply chains.

Digital Transformation and Supply Chain

My attention was caught by this article I read earlier today, Rising Shipping Costs Are Companies’ Latest Inflation Riddle. You can see growing evidence of complex business and economical relationships and the disruptive impact they can have on every company business.

How can you outcompete this crazy reality? The answer is simple – Data. It is not an accident that many people call data the new oil in the 21st century. Whoever gets access to the right data faster will be in a winning position. Earlier this week, Google announced their Google Supply Chain Twin, which can be a solution to help companies predict their supply chain future.

Here is the link to Google Supply Chain Twin – check it out. According to Google, the solution includes multiple elements – data segments, integrations with ERP systems, and integration partners. The following passage explains what Supply Chain Twin is.

This solution provides ready-to-deploy connectors and transformation pipelines based on Cloud Data Fusion to bring data from ERP systems like SAP into the BigQuery data platform. It uses Google Cloud public datasets and the Analytics Hub to enable secure access to curated datasets from multiple data providers without complex onboarding. This semantic layer spanning the private, community, and public data segments enables data to be leveraged directly and scalably for a variety of uses, including data science.

OpenBOM Multi-tenant Product Data Solution

However, here is a catch. The data in any “Digital Twin” is as good as the data you put in. When wrong or incomplete data is deployed to a digital twin, the results will be far from reality.

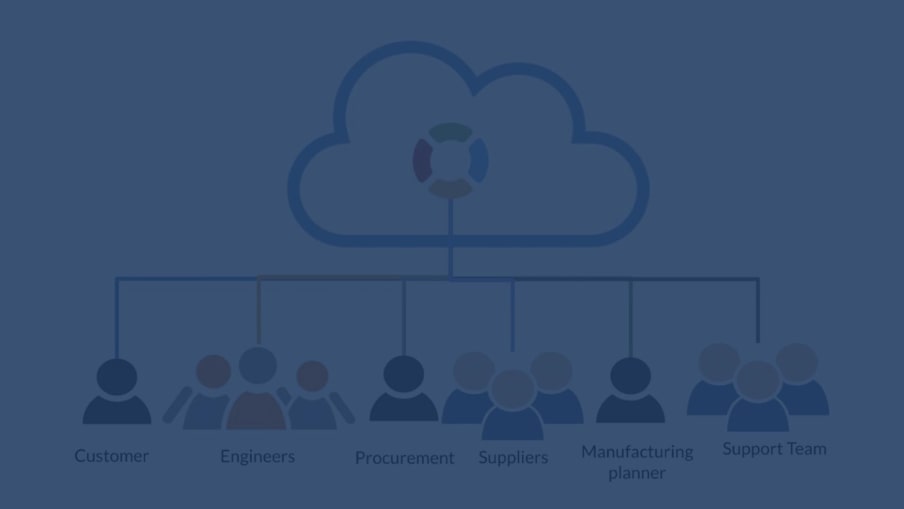

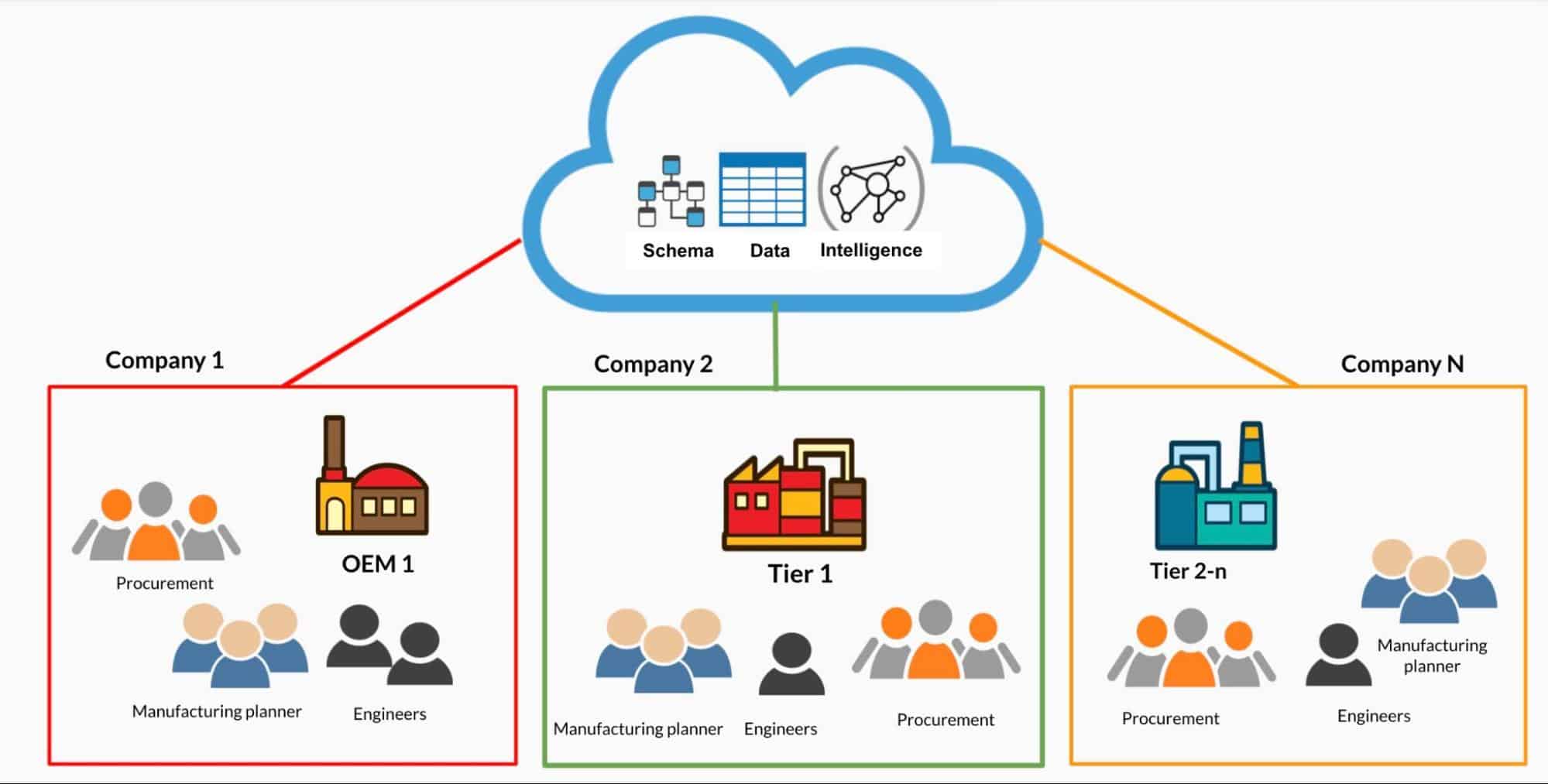

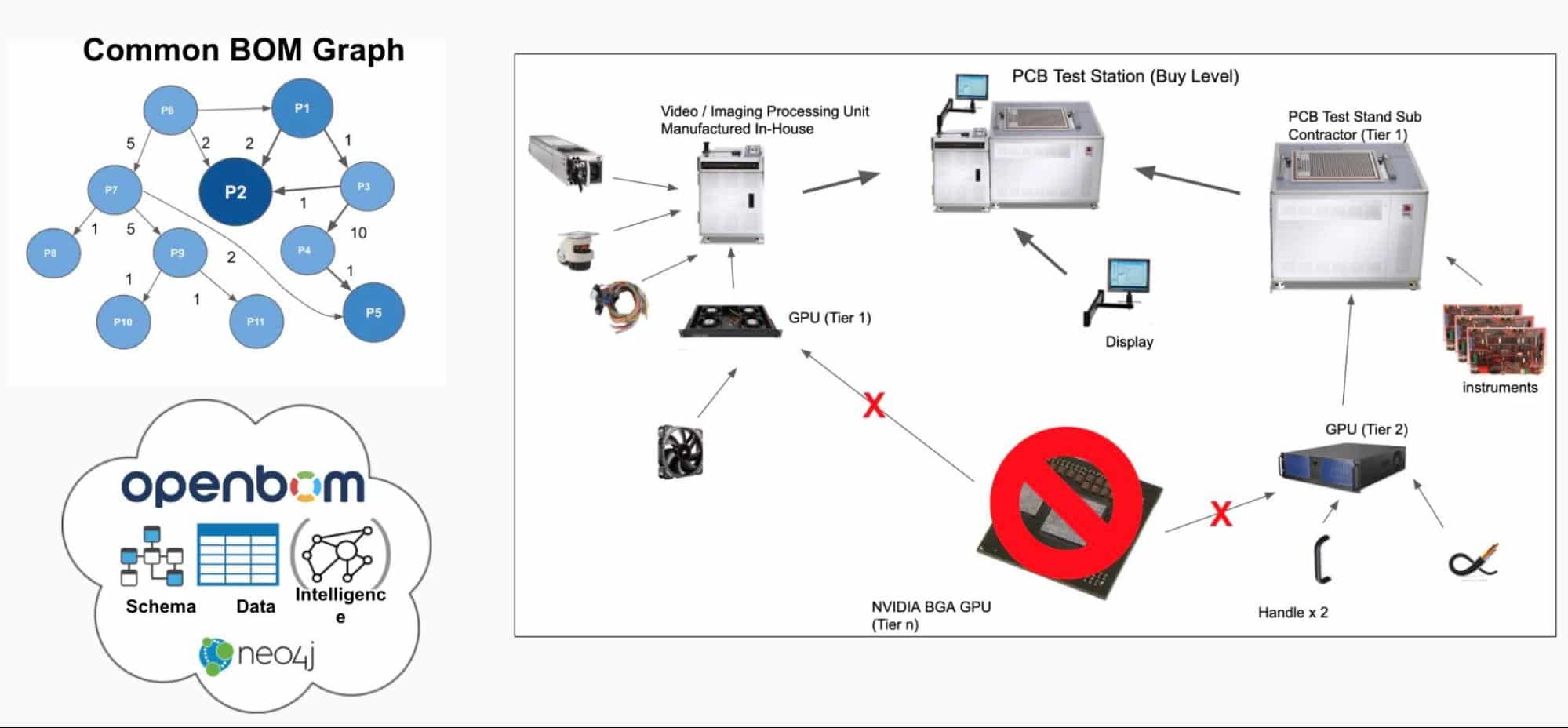

The biggest difference of OpenBOM is its global platform. OpenBOM connects data between multiple companies and by doing so can provide information that otherwise doesn’t exist as companies are communicating using OpenBOM.

.

Product Data Foundation

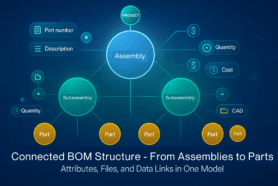

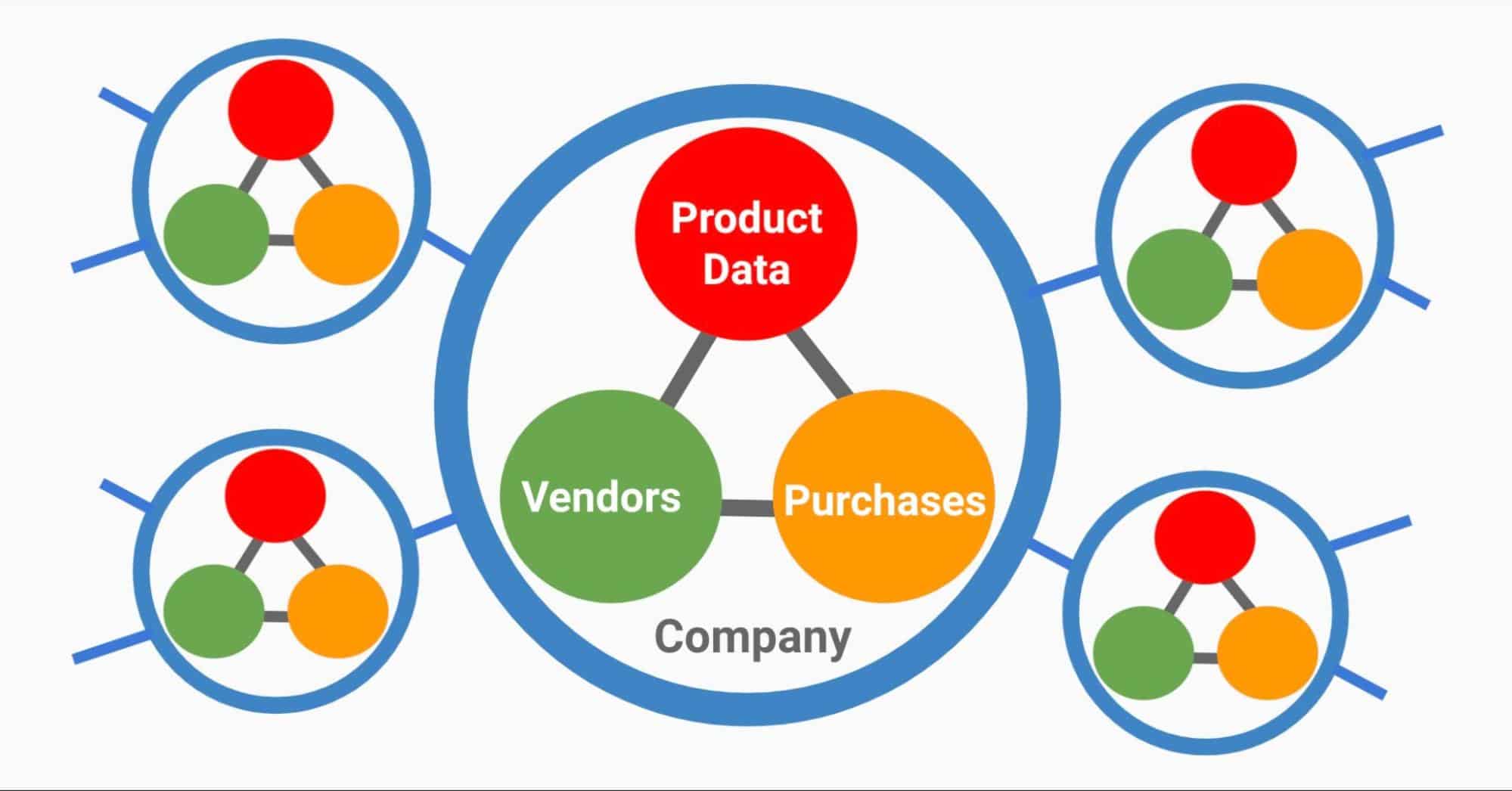

At OpenBOM, we are looking at how to manage the data on a broad scope. However, the foundation of the OpenBOM data management platform is product data. OpenBOM gives you core records about design, structure, item masters, and their relationships with suppliers, manufacturers, and other organizations. The fundamental triad of OpenBOM is combined from 3 data elements

- Product Structure (BOM) including Item Master

- Vendor

- Purchases

Getting back to Google Supply Chain Twin. According to Google, it provides a big data crunching service, which is capable of analyzing information, making predictions, and performing alerts. However, the system is as good as the data, and product information is absolutely necessary to make the correct prediction.

In the slide below, you can see how complex product relationships can find a supply chain bottleneck- specifically a part that is sourced from a single supplier. This is just one example of how unique product information can improve the quality of Digital Supply Chain (and other) Twin.

Getting the right data in the digital twin is an essential to bring the right results. And product data is a key data element to look after to solve many manufacturing and supply chain solutions.

Conclusion

OpenBOM is an ultimate source of product information. OpenBOM captures this information from engineering and design systems and can improve the intelligence of any Digital Twin solution by incorporating this information into their solution. This is how connected systems are built. By linking information, companies can triple the impact and the value.

Digital transformation is an ongoing process and effort to improve the way companies are running a business in the 21st century. It is not about how to capture the data records and hold it in a centralized legacy PLM database. It is about how to intertwine the information to provide a greater value (using data).

Check out what OpenBOM can do for you – REGISTER FOR FREE and start your 14-day trial today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.