As manufacturers know all too well, the business landscape is constantly changing and evolving. To stay ahead of the competition, it’s important to be prepared for whatever new challenges and disruptions come your way. Digital transformation is the way companies can get advantages and deliver new products and services faster with a predictable cost.

Digital transformation initiatives can be complex and companies can be confused about how to get up to speed and decide what is their action plan for digital transformation. One way to do this is by investing in a cloud-native PLM platform. With a cloud-native PLM platform, you’ll be able to quickly and easily adapt to changes in the market, while also gaining a competitive edge.

In this article, I will outline to you 3 main reasons why moving to cloud-native platforms such as OpenBOM, will take you ahead of possible disruption in product development, manufacturing, and supply chain.

Documents and Outdated Processes

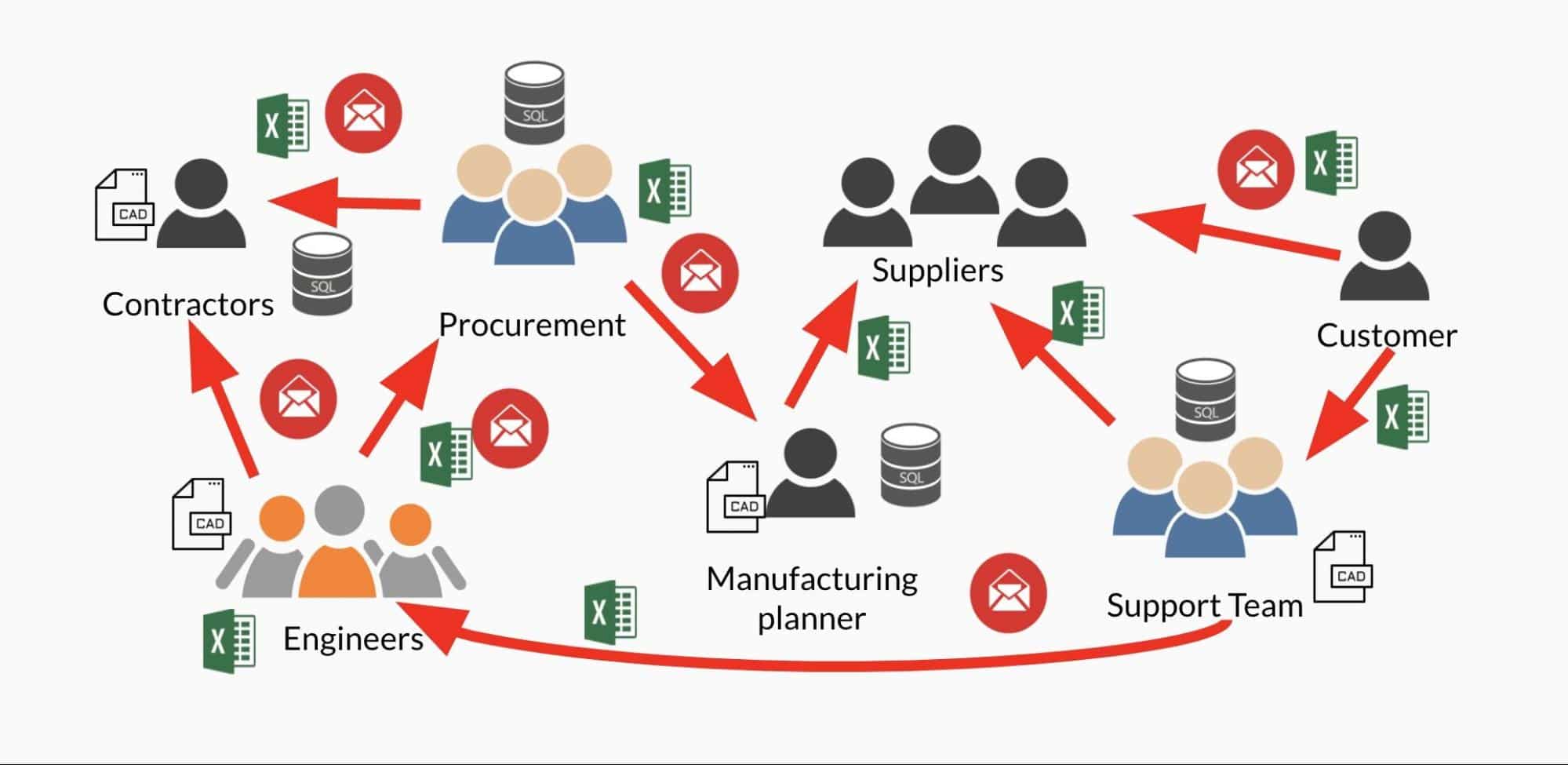

One of the core reasons for product development inefficiency is reliance on the old fashion way of managing information. For many years documents became a core paradigm used by companies. Organization of documents into folders, placing their CAD files, thinking about BOMs as spreadsheets, and transferring information using emails and attachments – this is how I see many companies still doing their business and managing business processes.

Take a look at the picture below and I’m sure you will recognize the problem immediately.

These businesses are missing the following problems that are not allowing them to achieve their product lifecycle management goals:

- A single source of truth about the product

- Revision and change management

- Upstream and downstream information flows

Every company that relies on Files, Folders, Excels, and Emails, will find itself with delays, missed cost targets, delayed deliveries, and, eventually, unhappy customers.

Why cloud-native and multi-tenant?

PLM systems have been around for almost three decades now, but most of these “mainstream” PLM systems were developed at a time when database-driven, single-server solutions were dominant. These solutions are still represented in 95% of production usage in PLM, but according to a leading analytical company in the PLM space, CIMdata, almost 70% of companies are looking at ways to replace their legacy PLM systems with modern cloud PLM systems.

While companies are looking for a better solution, it is important to understand the core difference between taking existing mainstream PLM systems and hosting them using AWS platform and cloud-native multi-tenant systems.

Here are 6 differentiation between these two architectures:

- Start immediately, instant trial, no upfront cost

- Infinite scale, no need to “plan hosted instances”

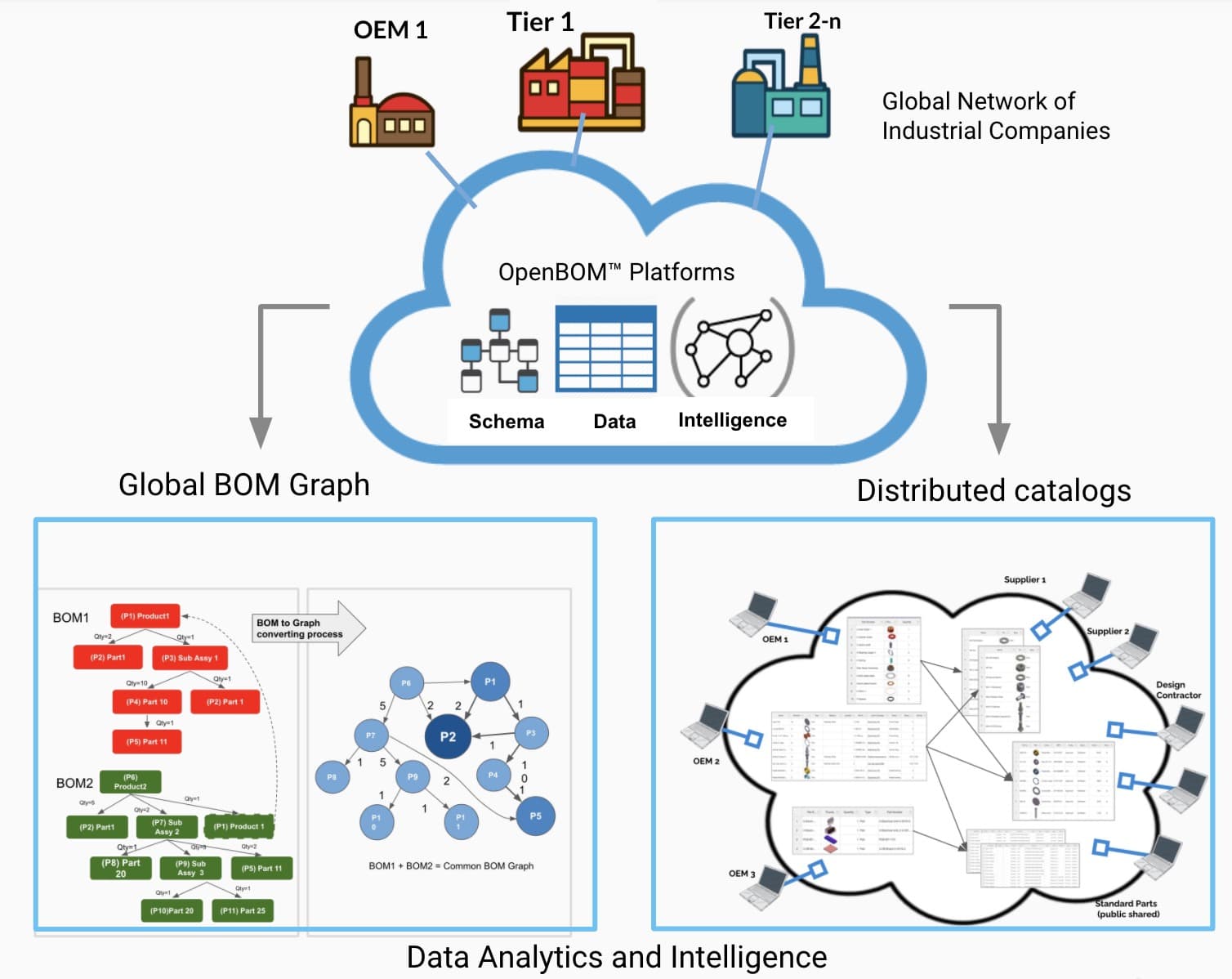

- Cross company collaboration and data sharing

- Engineering (CAD) integrations

- Seamless information flow

- Analytics and decision support

Stay Ahead Of Disruptive Events

You might be wondering how modern systems can keep you ahead of disruptions in the industry and why legacy systems or just Excel files cannot do it. Here are 3 examples of how systems can help.

1. Keep Data Organized with Global Access

Planning ahead and organizing a single source of truth about the product can be very helpful in the event of manufacturing disruption. In the event of the region or company manufacturing facilities shutdown, keeping data online and being able to share it with a new company (or team) can be crucial to stay afloat and continue to manufacture.

2. Eliminate Mistakes and Broken Information Flows.

Each time the data is copied between two different data sources (eg. files) or systems, there is a chance to introduce mistakes. In fact, each data copy can bring from 10-15% of mistakes in your BOMs. This is a huge number and companies can get in serious trouble by delivering wrong information to production teams and contract manufacturing companies. By enabling real-time data sharing, companies will eliminate mistakes and potential future problems.

3. History, Decision Support, and Analytics

Data is the new oil in the 21st century. Modern platforms can provide a very unique perspective on data, its connection and provide you with historical and analytical information about price fluctuations, suppliers’ reliability, cost changes, and many others. Having the right data at the right time is a super powerful feature that only becomes available on cloud-native platforms designed for analytics.

Conclusion

Now is the right time for manufacturing companies to think about data management transformation and seamless information flows. You just cannot stay ahead in the competitive race without getting all your data and insight about product lifecycle management, design, manufacturing, maintenance, and other processes. But these big goals can start with very small steps- getting data under control, preventing copy/pasting of data, streamlining communication, data changes, and quality.

OpenBOM gives you an instant way to start carrying about your data quality and integrity differently.

REGISTER FOR FREE and learn how OpenBOM can help today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.