I want to start with you a personal story today. Back in 2008, I started the Beyond PLM blog, with the main goal – to share knowledge and help people working involved in PLM to understand better products, technologies, and implementation best practices. It included multiple domains such as product data management (PDM), product lifecycle management (PLM), supply chain management, overall product development process, product lifecycle, integration with manufacturing, and a deep look into technologies that are used for PLM.

My idea was to share knowledge and create meaningful dialogue within the Product Lifecycle Management (PLM) community. Turned out, the blog became a way to communicate and build relationships with many people in different companies and countries. Over the years, I have interacted with thousands of people—sharing ideas, discussing issues, and constantly learning. My main takeaway from all these years is that people are the key element in PLM technology adoption.

Years later, when I started OpenBOM, we put education as one of the core elements of our strategy. Our goals were always to facilitate the dialog with customers, to understand their needs, to help them to adopt technologies we developed at OpenBOM, and by doing so, to help us to improve OpenBOM products and to guide our future development. Check this video to learn more about the story of OpenBOM:

In this article, I want to talk about the top elements of PLM technology adoption and one main mistake many companies (especially small ones) make when approaching PLM implementation.

Tech is only useful if people can use it

Designing and building products is hard and therefore companies to manage production processes, business processes, focus on product quality, and business strategy. One thing that I have always emphasized is the human element in technology adoption. PLM technology, no matter how sophisticated or robust, is only beneficial if people can effectively use it. Too often, organizations fail in adopting PLM, not due to the technological complexities of the system, and not because of the technology’s lack of some features, but because they aren’t prepared for the process change that comes along with it. Even worst, small and medium-sized companies don’t have the right process in place. Their organizations are either too small to think about processes or growing fast and processes come as an afterthought. It is extremely important to think about multiple disciplines such as computer-aided systems, document management systems, PLM systems, and many others.

PLM playbook – process, people, data, implementation

One of the most common mistakes for PLM adoption I can see is to start it in the wrong place. Data is a central element of any PLM implementation. What is often sold as “PLM is a single source of truth”, which is translated as a “single database” to store all data. Companies often jump into the flow or “syncing” data to a single database, without giving a minimum thought about other aspects of PLM implementation, especially process and people.

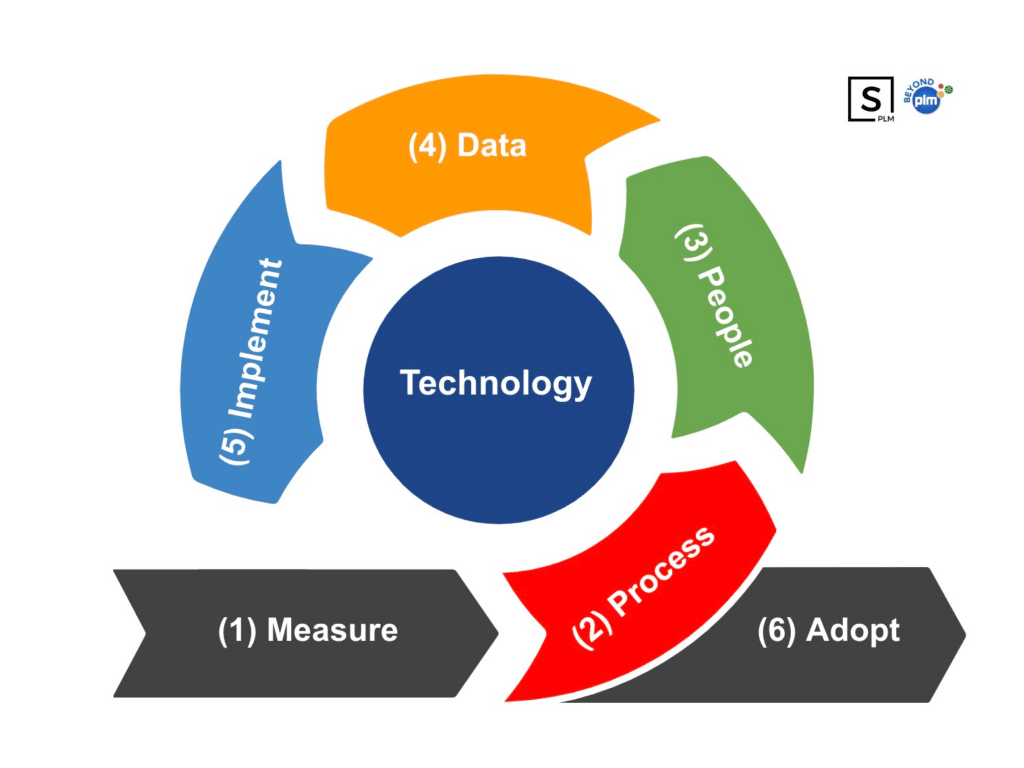

This lack of readiness often boils down to a fundamental misalignment in the process, people, data, and implementation facets of PLM adoption. PLM technology adoption spins around these four aspects:

- Organizational process

- People, roles, and organizations

- Data about the product and all related information

- Implementation and training

In the PLM playbook, I published on the Beyond PLM blog, I define it as a continuous cycle going in adoption sprints (implementation phases).

Technology is a foundational part of this cycle, but without all other elements, technology alone won’t survive. So, what are the most typical mistakes in PLM technology adoption? It is to start from “data sync”.

Data and a Single Source of Truth are important, but…

While a single source of truth and data is one of the key elements of PLM tech, jumping quickly into a ‘data’ can trigger very unfortunate rejection. Here is how it happens.

Many manufacturing companies (especially small and medium-sized companies) start the adoption process incorrectly by focusing primarily on ‘data.’ They attempt to store, organize, and push data between applications. It often starts as a way to think about “CAD files” and “BOM excels”, and continues to downstream business systems (if they exist). Companies are trying to bring them together and “push” information between applications. A very typical example is to push data from design/engineering (CAD) to manufacturing (ERP/accounting/finance). Doing it without the right process in place is a fatal mistake that will cost you time, money, and people conflicts. It will trigger debates about “who owns the data” and leads to multiple misalignment in the way data will be managed.

While data management is a key aspect of PLM, starting with data is a misguided approach as it misses the most critical elements – people and processes. Let’s talk about it…

Processes, People, and Information Flow

Process setup is the core of successful PLM adoption. Without defined processes, data loses its relevance and applicability. Companies need to set up the process first and ensure a seamless flow of information to support these processes. By doing so, they lay the foundation for meaningful and effective use of PLM technology to support their business.

How to do so in the right way? You need to apply the process thinking, identify key processes you want to transform, decide about who (people) need to be involved, and then draw an information flow diagram that explains how data is managed in the organization and exchanged by multiple applications and services (these days it is extremely important because SaaS tools provide a very efficient way to integrate data flow using REST APIs).

How OpenBOM Can Help?

At OpenBOM, we provide robust and flexible technology that can help your product lifecycle management efforts. However, merely having technology isn’t enough. Companies need to set up their processes first. We understand this crucial requirement and hence, assist with comprehensive onboarding training to aid in the process setup.

Often, companies try to “jump” and quickly “sync” data, hoping for instant results. This approach can lead to disappointment as they find themselves attempting to “computerize the mess” without first organizing and cleaning up their processes. The key is to first create order, clean the mess, and then introduce technology to streamline and optimize the newly organized system.

OpenBOM’s technology is not just a tool, but a facilitator to create a better set of processes for your organization. Therefore, setting up the process and defining goals must be the primary focus before diving into organizing and processing data. During the onboarding training and ongoing support, we help organizations to collaborate and define the process and core information flow in an organization.

Conclusion:

While OpenBOM provides robust and flexible technology, it’s the setup of the process and the clear definition of goals that ensure successful adoption. We are committed to helping hardware teams and manufacturing companies adopt OpenBOM technology by focusing on these crucial steps. Remember, the path to successful PLM adoption is through collaboration, process definition, and then data organization and processing. Technology is the final piece of the puzzle that ties everything together to deliver efficient and effective product lifecycle management.

REGISTER FOR FREE to check how OpenBOM can help you. Contact the OpenBOM team directly if you want to discuss your next PLM transformation project.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.