Digital transformation is forcing organizations to rethink how they manage and utilize product data. While industries have been embracing new technologies, the fundamental problem remains: product data is still trapped in outdated paradigms that slow efficiency and decision-making in engineering teams and manufacturing organizations.

Understanding and focusing on product data is the most critical element of digital transformation because it forms the foundation of every business process in manufacturing. From design and engineering to production, procurement, and customer service, product data must be seamlessly connected to ensure operational efficiency and business agility. Without a well-structured and integrated product data strategy, companies struggle with inefficiencies, miscommunication, and data silos that slow down decision-making and hinder competitive advantage.

Product data is not just a set of attributes or a collection of files; it is the digital representation of everything a company designs, builds, and sells. It includes configurations, relationships, versions, and dependencies that impact the entire lifecycle of a product. In an era where businesses must adapt quickly to market changes, having an accurate, accessible, and connected product data layer is no longer a luxury – it is a necessity. Companies that fail to prioritize product data management will find themselves lagging behind more agile competitors who leverage data-driven insights to optimize development, reduce costs, and improve customer satisfaction.

The Status Quo: PLM’s Failure to Deliver on Product Data

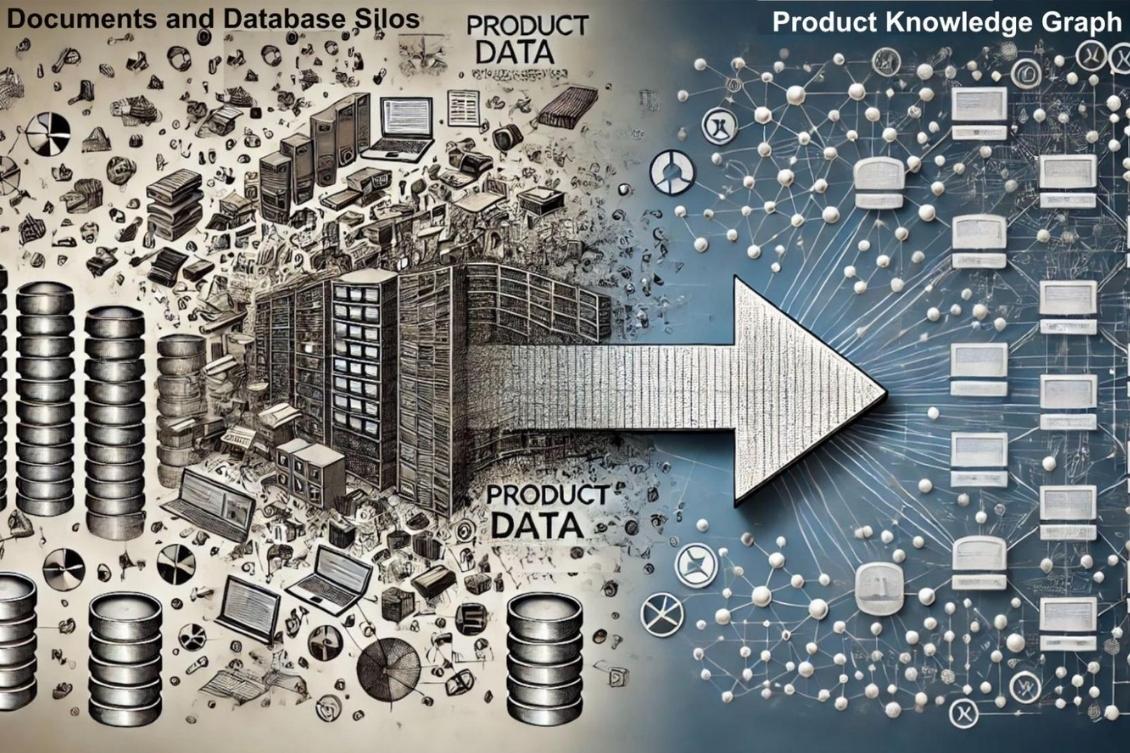

For decades, PLM has struggled to provide a robust mechanism for organizing product information. Instead of fostering connectivity and transparency, traditional PLM solutions have contributed to data silos. Let’s examine some of the fundamental issues:

- Legacy Document Paradigm – Companies have historically relied on files, folders, and vaults to store and manage product data. This approach comes from an outdated document-centric philosophy that lacks the flexibility needed in modern data environments.

- PDM as File Controller – While databases were introduced in Product Data Management (PDM), their primary function was to act as controllers for file records rather than enabling granular data-driven product management.

- PLM’s Limited Scope – Despite being designed to manage the entire product lifecycle, PLM software is still largely used for engineering-focused tasks such as design management and engineering change workflows. The broader promise of PLM – connecting data across an enterprise – was never delivered.

- Inefficient Data Exchange – The primary method for sharing PLM data with downstream functions such as manufacturing, procurement, and service is still through massive Excel exports and data synchronization between disparate databases. This creates inefficiencies, version conflicts, and data fragmentation.

- Data Ownership Conflicts – There is a continuous struggle between PLM and other enterprise systems (such as ERP) over who owns key product data. For example, MBOM (Manufacturing BOM) ownership disputes have reinforced the development of walled gardens, making seamless integration difficult.

Leveraging Modern Data Management Technologies

The good news is that data management technologies have matured significantly. The emergence of cloud-native architectures, document databases, graph databases, and AI-driven analytics (including LLMs) has created an opportunity to rethink how product data is structured and utilized.

The foundation of product data is configured items (CIs) – basic foundational elements that allow us to model everything. Organizations can build a product data layer that makes configuration items (CIs) transparent, enabling full contextual knowledge of products throughout their lifecycle.

This approach will provide:

- A unified layer of information for all product-related data.

- A connected and contextual view of engineering, manufacturing, supply chain, and service data.

- Improved decision-making through better insights into product configurations, usage patterns, and lifecycle analytics.

- Greater interoperability between PDM, PLM, ERP, MES, CRM, and other enterprise systems.

Investing in “Data Products” to Unlock Value

Organizations must shift their focus toward developing data products that represent actionable knowledge about their products and operations. This includes:

- Understanding what products are built and how they evolve over time.

- Analyzing how customers use products to drive future enhancements.

- Creating data-driven strategies for maintenance, service, and recycling to improve product lifecycle management.

- Developing AI-powered insights to optimize new product development and change management.

Conclusion: Building the Digital Product Data Foundation

To “get product data,” manufacturing companies must build a digital product data foundation that eliminates silos and enhances collaboration across the organization. This foundation will streamline critical processes such as new product development, change management, customer support, maintenance, and operations. By embracing modern data technologies and investing in structured product data strategies, organizations can unlock new levels of efficiency, innovation, and competitiveness in the digital era.

At OpenBOM, we innovate in building a Collaborative Workspace platform that uses innovative data management to organize data information using the Product Knowledge Graph paradigm.

Contact us to discuss more about how we can help to build a better data strategy for your organization.

REGISTER FOR FREE and try OpenBOM for 14 days. Check more about OpenBOM Trial Consulting Program.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.