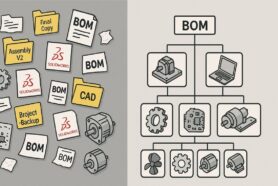

Sharing data with your contract manufacturer (CM) is a critical step in the manufacturing process, but it’s far from simple. Whether you’re sending BOMs, CAD drawings, or specifications, ensuring your CM has accurate and up-to-date information can be challenging. The traditional methods of sharing data—emailing spreadsheets, relying on static files, or juggling multiple file versions—are inefficient and prone to errors.

Without a streamlined process, miscommunication becomes inevitable. Outdated files, conflicting revisions, and unclear instructions can lead to delays, production errors, or even damaged supplier relationships. The more complex your product data, the greater the risk of something slipping through the cracks.

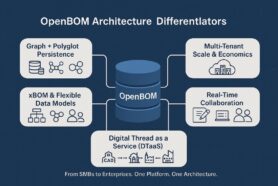

That’s where OpenBOM’s collaborative workspace comes in. Designed to tackle these challenges, it enables seamless, real-time data sharing between your team and your CM. In this blog, we’ll explore the traditional pain points of sharing data with your CM and how a collaborative workspace simplifies the process, improves communication, and reduces costly errors.

The Traditional Challenges of Sharing Data with Your Contract Manufacturer

Sharing data with your CM is a critical step in ensuring smooth production, but traditional methods make this process far more difficult than it needs to be. From managing Excel files to dealing with breakdowns in communication, these outdated approaches create inefficiencies and increase the likelihood of errors. Here are some of the most common challenges companies face when sharing data with their CMs.

Version Control Issues

Many companies rely on Excel or file based folder structures to share data with their CMs. These files are often sent via email, creating a fragmented process where updates require resending revised files. It’s easy to lose track of which version is the most up-to-date, and this lack of a single source of truth can result in CMs working with outdated or incorrect information. The consequences? Incorrect quotes, material errors, and unnecessary production delays.

Communication Gaps

Sharing data via email or other methods, such as WeChat, if you are dealing with Chinese suppliers, often leads to back-and-forth exchanges filled with questions, clarifications, and corrections. These delays are compounded when teams operate in different time zones or when critical stakeholders are unavailable to respond quickly. For example, a missing material spec or unclear BOM might require multiple emails to resolve, slowing down the RFQ process and ultimately delaying production timelines.

Lack of Real-Time Updates

In traditional data-sharing methods, there is no centralized location where all stakeholders can access the same, up-to-date information. CMs are often left in the dark, working with incomplete or unclear data. Without a way to collaborate in real-time, they might make assumptions about materials, quantities, or specifications, leading to costly mistakes that could have been avoided with better visibility.

Increased Risk of Errors

Manual processes are generally error-prone. Whether it’s accidentally sending the wrong file, overlooking an updated revision, or purchasing the wrong parts, traditional methods leave room for human mistakes. These errors can snowball, affecting not just the CM’s output but also your overall production timeline and budget.

Traditional methods of data sharing often hinder collaboration instead of fostering it. To overcome these challenges, companies need a more streamlined, transparent, and collaborative approach to sharing data with their CMs, a solution that ensures everyone is working from the same page at all times.

How a Collaborative Workspace Streamlines Data Sharing

A collaborative workspace fundamentally changes how data is shared and managed between you and your CM. By creating a centralized, real-time environment, it eliminates many of the inefficiencies and risks associated with traditional data-sharing methods. Here’s how a collaborative workspace transforms the process:

Centralized Source of Truth

A collaborative workspace ensures that everyone on your team and external partners, such as your CM all have access to the same, up-to-date information. Whether it’s a BOM, CAD files, or work instructions, everyone works from a single source of truth, eliminating confusion about which version is correct. Updates made by one user are immediately visible to others, ensuring that your CM always has the latest data without needing to sift through emails or multiple file versions.

Real-Time Collaboration

Unlike Excel files, a collaborative workspace allows for updates to be visible in real-time. Think of changes made to a Google Doc, you can see those instantly. Multiple users can work on the same data simultaneously, with changes automatically captured and logged. For example, if your team updates a material specification or changes a part quantity, your CM can see and act on those updates instantly. This reduces delays, streamlines communication, and ensures that your CM has the information they need to keep the project on track.

Improved Access Control

A collaborative workspace provides granular access control, allowing you to decide who can view or edit specific data. You can securely share only the information your CM needs while keeping sensitive or proprietary data restricted to team members who need it. This level of control not only enhances security but also ensures that your CM is focused on the details relevant to their work.

Enhanced Transparency

With a collaborative workspace, you gain full visibility into the data-sharing process. You can track who made changes, when those changes were made, and what was updated. This transparency helps to improve accountability, as both your team and your CM can easily identify and resolve issues before they become larger problems. It also fosters trust, as your CM knows they’re working with accurate and reliable information.

Faster RFQ and Production Processes

By removing bottlenecks like email chains and file versioning, a collaborative workspace accelerates the RFQ process. Your CM can review and quote based on accurate data, reducing back-and-forth communication and speeding up approvals. Similarly, during production, having immediate access to updated data helps avoid delays caused by miscommunication or missing information.

Seamless Integration with Existing Tools

Modern collaborative workspaces, like OpenBOM, integrate with the tools you’re already using, such as CAD systems and ERPs. This means your data flows seamlessly from design to procurement, reducing the need for manual data entry or file exports. For your CM, this integration ensures they receive data in a format that’s easy to work with, further simplifying the process.

A collaborative workspace isn’t just a tool, it’s a solution that bridges the gap between your team and your CM. By enabling real-time collaboration, providing a centralized source of truth, and improving transparency, it helps streamline data sharing, reduces the risk of errors, and keeps your projects running smoothly.

Conclusion

Sharing data with your CM has always been a critical and challenging part of the manufacturing process. Traditional methods, such as emailing Excel files or relying on disconnected systems, often lead to version control issues, communication delays, and errors that can slow down production and increase costs. These inefficiencies highlight the need for a better approach.

Are you looking for a collaborative workspace? Let’s get in touch! We would be happy to show you our solution.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.