In today’s fast-moving world of innovation, the way we interact with technology is constantly evolving. One of the latest breakthroughs in home entertainment comes from Displace TV, a company rethinking how televisions are mounted. Their wireless, vacuum-powered TV mounting system is a game-changer, eliminating the need for bulky wall mounts and complicated installation. But behind every great product is an efficient design and manufacturing process—and that’s where OpenBOM comes in.

Displace TV: A New Era of TV Mounting

Imagine a completely wireless television—no power cords, no mounting brackets, and no drilling into walls. That’s exactly what Displace TV has developed. Their vacuum-powered mounting system allows users to place a TV on virtually any surface with a secure, yet easily removable, suction-based attachment. This innovation not only transforms the aesthetics of modern living spaces but also makes installation effortless.

While the concept is simple, bringing this innovation to life requires complex engineering, precise manufacturing, and seamless collaboration between teams. Managing the vast number of parts, engineering revisions, and production details is a challenge—one that traditional file management tools like Google Drive simply couldn’t handle.

The Challenge: Organizing Complex Product Design and Manufacturing

As Displace TV scaled up its development, the team faced a growing challenge:

- Managing multiple SolidWorks CAD designs across engineers

- Ensuring accurate part lists and Bill of Materials (BOM) for production

- Preventing data overwrites and maintaining version control

- Keeping distributed teams aligned on the latest engineering updates

Initially, Displace TV relied on Google Drive to store and share design files, but this approach quickly became unmanageable. Engineers accidentally overwrote each other’s work, design files were difficult to track, and production planning lacked the necessary structure.

To bring order to the chaos, Displace TV turned to OpenBOM.

How OpenBOM Transformed Displace TV’s Workflow

Displace TV implemented OpenBOM to organize and streamline their engineering and manufacturing processes. Here’s how it made a difference:

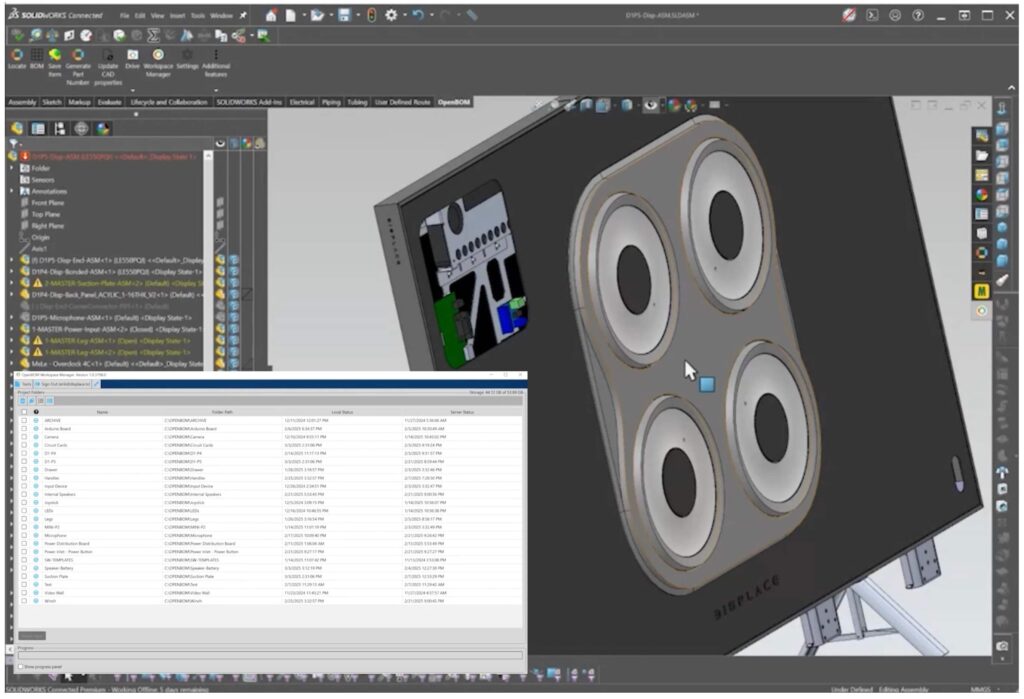

1. Seamless SolidWorks Design Management

Using OpenBOM’s integration with SolidWorks, Displace TV was able to automatically extract CAD metadata, parts, and BOM structures, ensuring that every engineer worked with up-to-date data. Instead of manually managing spreadsheets, OpenBOM synchronized design changes and prevented inconsistencies.

2. Collaborative Workspace for Distributed Teams

With engineers working across multiple locations, OpenBOM’s Workspace Manager allowed Displace TV to centralize their projects, giving every team member access to the latest information. No more file conflicts, no more lost data—just seamless collaboration.

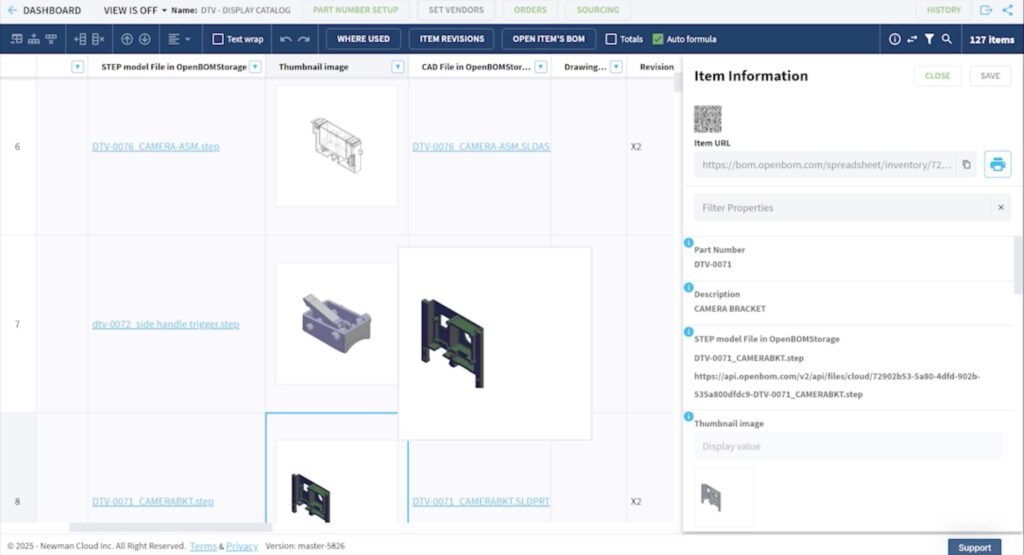

3. Organizing BOMs and Part Management

OpenBOM helped structure and maintain BOMs, enabling Displace TV to track components, materials, and suppliers in a single, unified system. This made it easy to move from design to manufacturing with complete visibility into parts and costs.

4. Instant Access to Critical Data

Instead of searching through endless files, engineers could pull the latest information instantly, ensuring the right design data was always at hand when needed for production.

Video Demo

Check the video interview and story about OpenBOM at Displace TV.

Conclusion:

OpenBOM brings chaos to clarity Displace TV’s journey from an innovative idea to a fully engineered product required a robust, flexible, and collaborative solution. OpenBOM helped them eliminate data silos, streamline engineering workflows, and accelerate their product development—all while supporting their vision for a truly wireless and effortless TV experience.

By replacing outdated file-sharing methods with OpenBOM’s structured approach, Displace TV can now focus on what they do best—bringing the future of TV mounting to life.

Interested in how OpenBOM can help your team organize product development and manufacturing? Visit OpenBOM and start your journey toward a more efficient workflow today!

REGISTER FOR FREE and check this out.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.