Imagine a robot capable to handpick fruits and vegetables with the precision of a human hand and place it in the storage box? It uses a variety of technologies including a proprietary gripper, twelve arm multi-axis robotic hand, computer vision, artificial intelligence learning about different types of fruits, and others. FF Robotics does it, but together with that comes the challenge of components and BOM management.

“With over 16K individual parts, we needed a better way to manage components,” says FFRobotics co-founder Yoav Koster. As you can imagine, the machine that mimics the gentleness of a human requires sophistication and precision, so FF Robotics selected OpenBOM to speed that innovation to market.

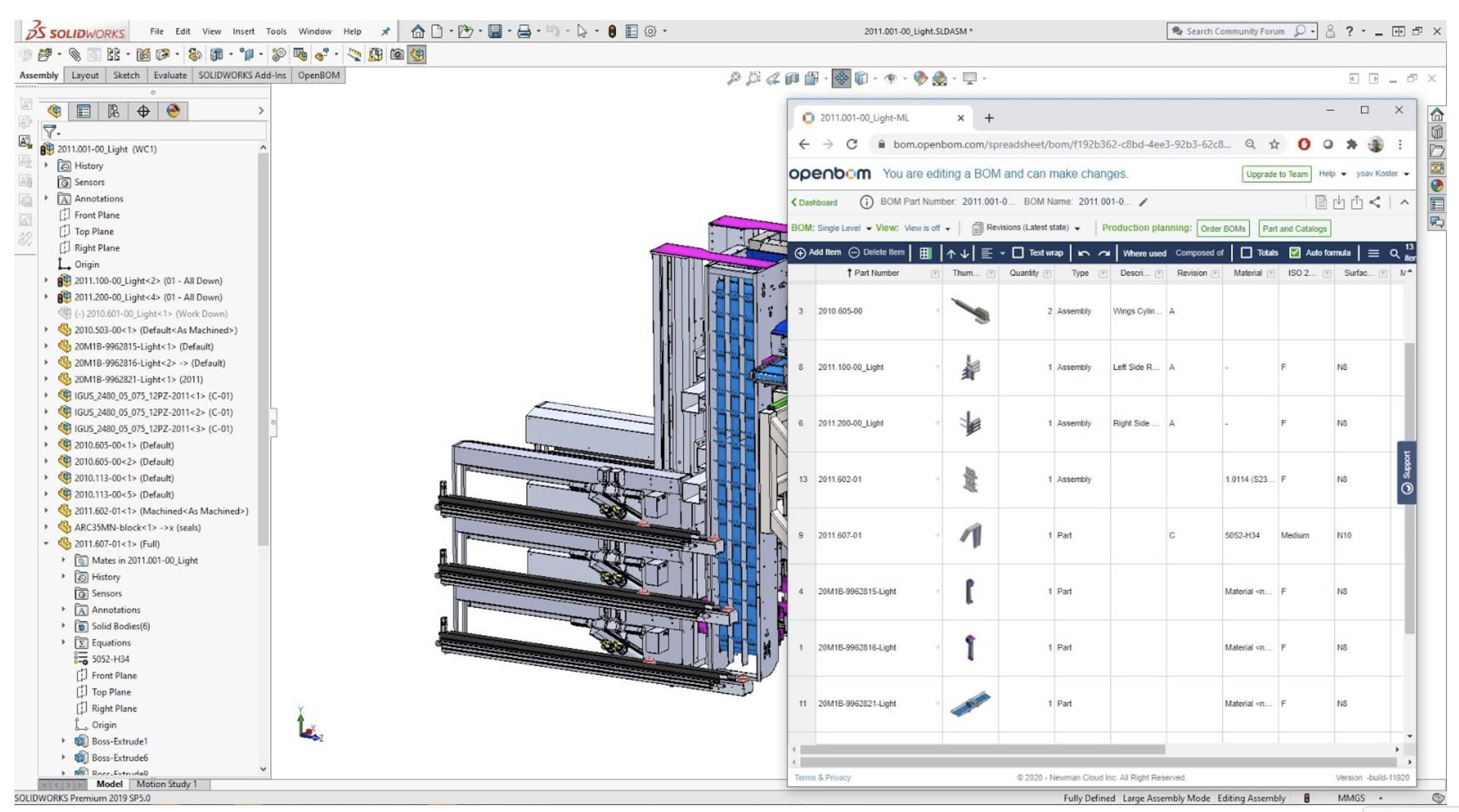

The challenge of FF Robotics was to extract BOMs directly from Solidworks and then organize them and manage updates all the time. OpenBOM Solidworks integration helped FF Robotics to do so and get rid of annoying Excel files with manual data handling.

“Getting our BOMs out of Solidworks in Excel was hard. We would add some non-modeled items like hardware then have to manage all those additions individually each time we updated the Excel from Solidworks”. Using OpenBOM with SolidWorks and PDMWorks is much much easier, he says.

Even automation of BOM extraction was already a huge time saver, it was only the beginning. The real optimization started after BOMs were created. FF Robotics was looking at how to optimize its components based, fasteners to save cost.

Here is what Yoav Koster, the co-founder of FF Robotics explained:

“OpenBOM easily manages and tracks our part numbers” he goes on to say, “something as simple as finding where a part is used is easy with OpenBOM’s where-used command; not having to open our CAD and look for a part is a huge time saving.”

Yoav explains in more detail how “Once we had our BOM’s in OpenBOM the real optimization began. We used OpenBOM to identify places where we could standardize. For example, we standardized and significantly reduced our fastener and bearing part numbers. We want fewer part numbers and more standardization. With very little effort we combined standard parts to reduce the BOM significantly. Saving time and money.”

But that comes even more value- the ability of OpenBOM to share the data.

“Something we didn’t anticipate was the ease of sharing the BOM with the rest of our team. We have a property for Make or Buy which we set in the Catalog. FF Robotics purchasing department gets the BOM and knows exactly what to do. We could have done it before but it demanded more work and sometimes it just didn’t get done or we made some mistakes.”

FF Robotics does some amazing things. Check out the following video about how the FF Robotics arm works.

Conclusion

Components and BOM management is a complex task and it requires a lot of effort and work if it is done using old-fashioned Excel spreadsheets. OpenBOM SaaS opens a new way to manage BOM, optimize components usages, and standardize parts using cloud-based data management technologies, seamless integration with CAD tools, and instant data sharing.

Meantime, you can check what OpenBOM does by registering for FREE and start a 14-days FREE professional trial just by clicking the button. If you already have an OpenBOM account, just click on the “Start Trial” button. No subscription, no annual commitment, and no credit card needed to try it out.

Best, Oleg @ openbom.com

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.