Data is the new oil, which can provide a huge value in modern business. If you look around these days, you will see multiple examples of how businesses are creating tons of value of data and data sharing. Yet, in manufacturing, data sharing is still in the infancy.

World Economic Forum publication Share to Gain: Unlocking Data Value in Manufacturing brings interesting evidence and examples of how data sharing can fuel the future of manufacturing

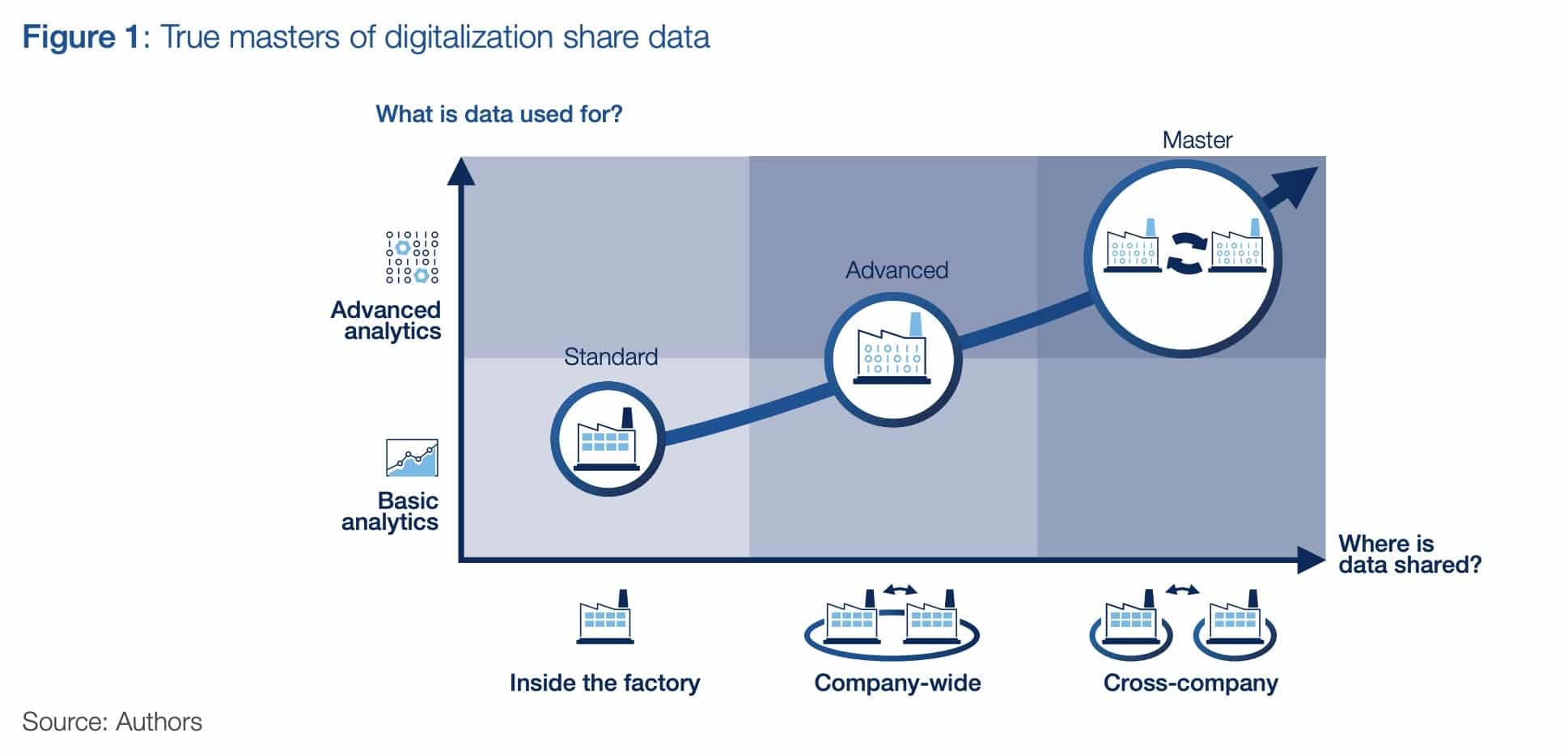

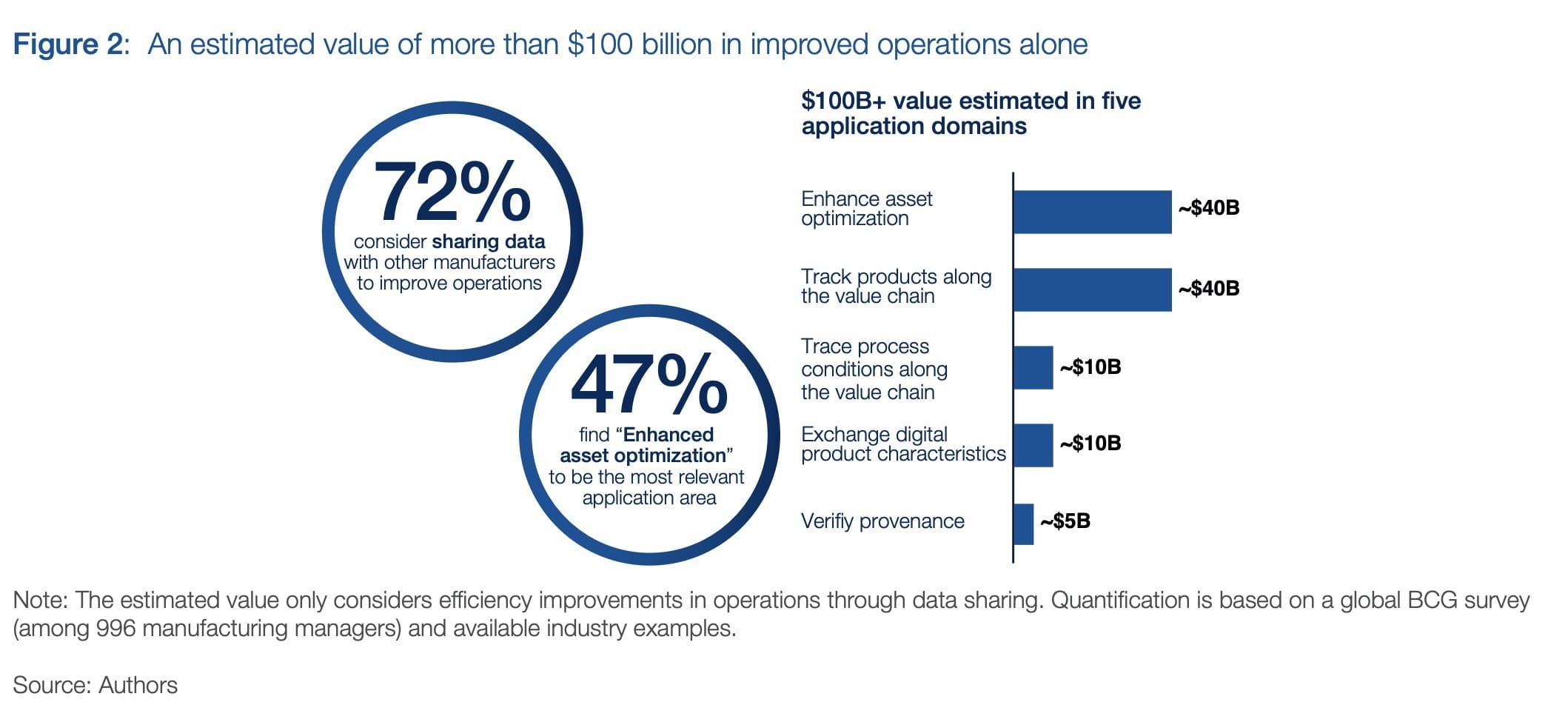

Emerging technologies such as advanced analytics and artificial intelligence (AI) are transforming the world of production. Although manufacturers are making strides in applying data-driven technologies, most focus on applications within their companies and have difficulty maximizing their return on investment. By sharing data across companies, manufacturers can unlock additional value and accelerate innovation. The potential value of data sharing simply by focusing on manufacturing process optimization has been estimated at over $100 billion, based on best practices.

According to the publications, there are 5 main areas – (1) asset optimization such as combing information about materials or part usage across multiple users; (2) tracking products along the value chain, for example, react to unexpected events in the supply chain; (3) tracking process conditions across the value chain, for example, to validate suppliers following the right manufacturing and process requirements; (4) exchanging digital product information across multiple manufacturers (OEM and suppliers), for example, to simplify the testing and validation; (5) verifying the provenance when it comes to materials and resources used for product development.

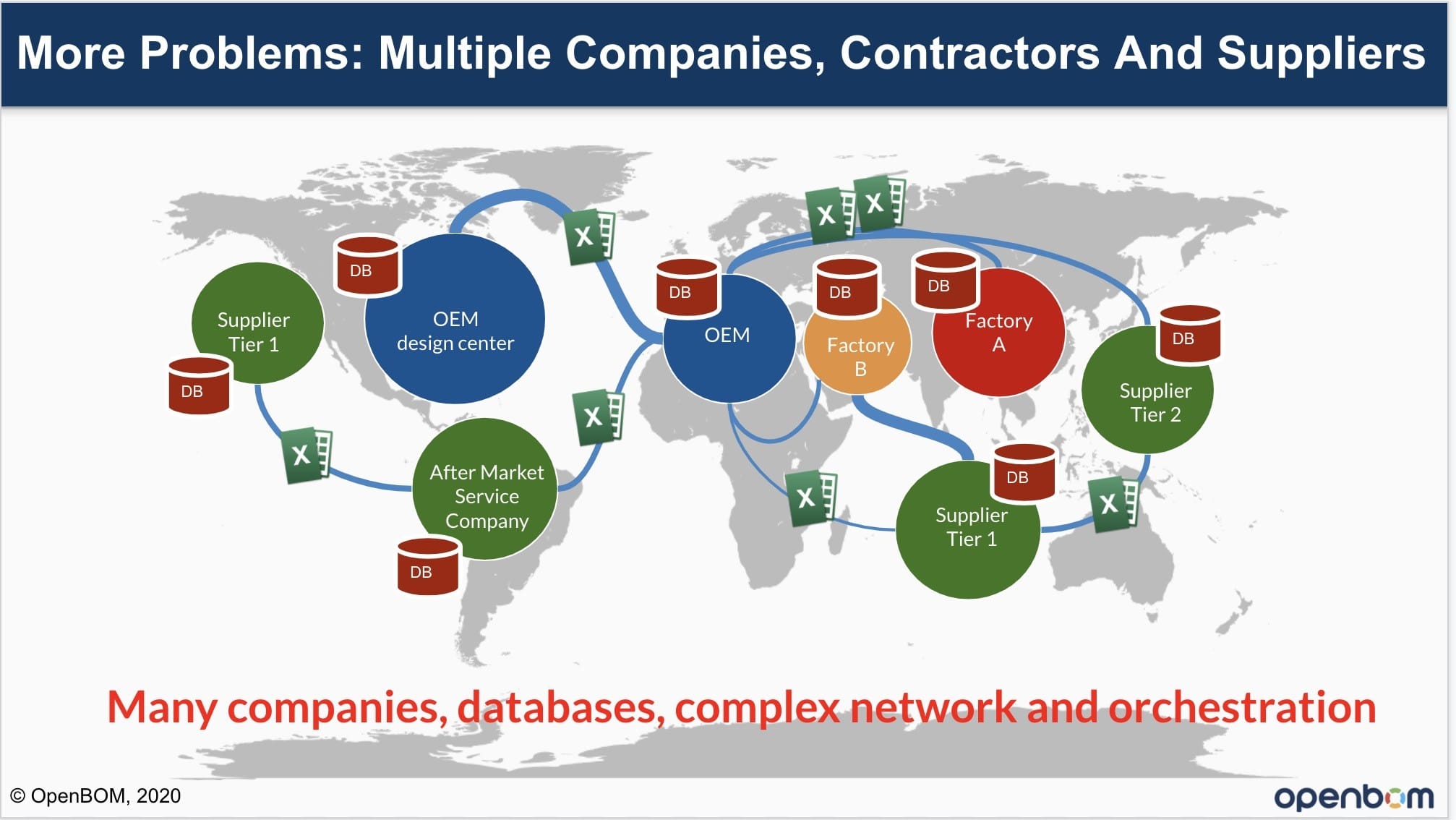

But to make such things will happen manufacturing companies must rely on the right set of technologies. The article speaks about a variety of technologies that can help manufacturing companies to share data more efficiently and to eliminate bottlenecks created by old technologies.

Existing single-tenant PLM technologies is one of the bottlenecks towards gaining the value of data sharing. The data located in isolated PLM databases hardly can be shared. We talked about this problem earlier this week when presented OpenBOM SaaS PLM for Onshape.

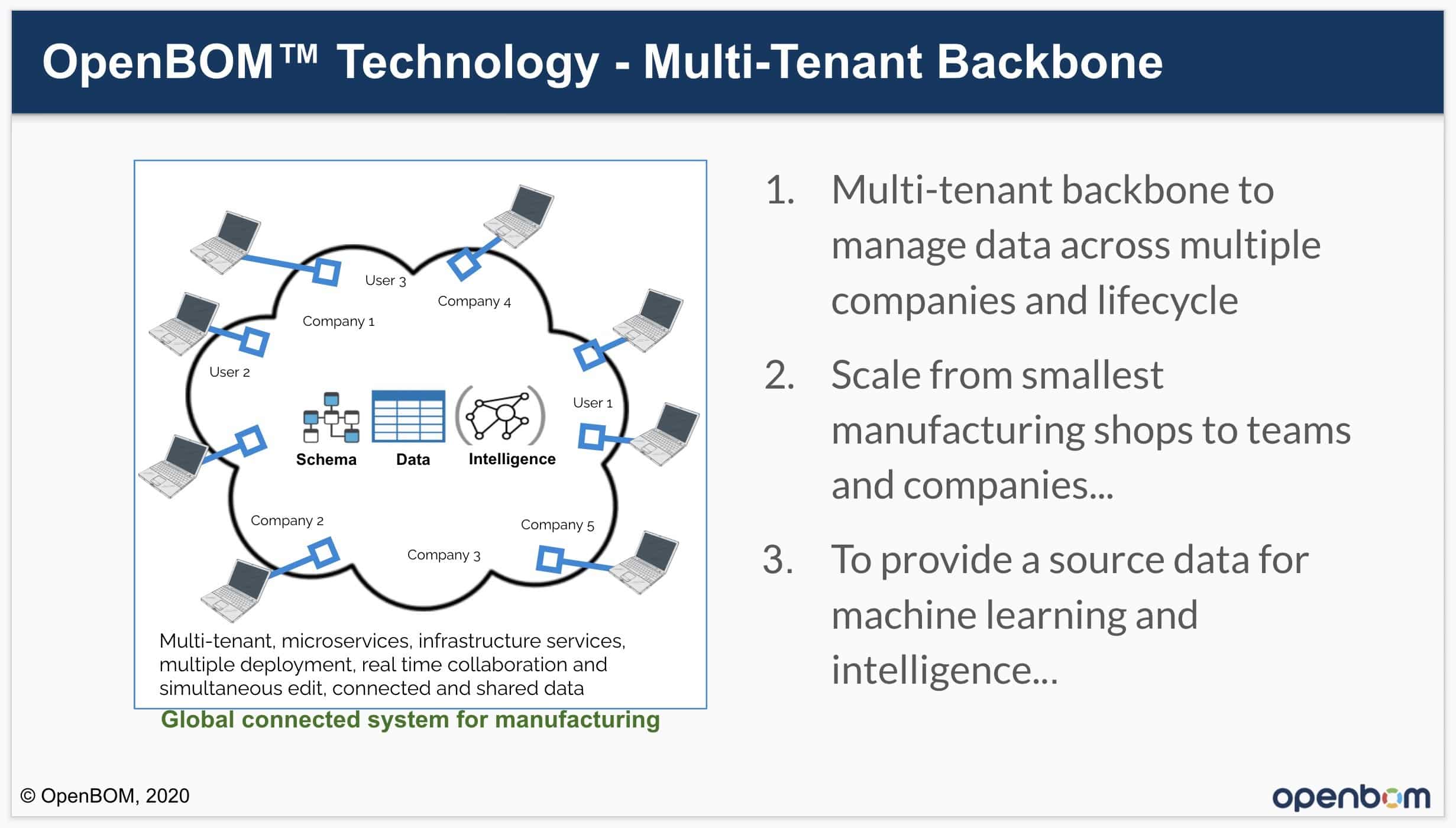

In my Beyond PLM article – 5 Dimensions to Compare Single Tenant vs Multi-Tenant PLM Cloud Models, I shared details on how PLM architecture and tenant management can be the key enabler to change PLM architecture towards data openness and data sharing. Advanced analytics and machine learning can be applied to common data sets in multi-tenant PLM platforms and become the source of future intelligence and business values.

Existing PLM vendors have a huge investment in existing single-tenant systems. Multi-tenant architecture has a lot of potentials, but it still needs more time to come to maturity. As a customer, you should be looking at how the system fits your business needs and it is a combination of function, cost, future upgrades, ease of use, and simplicity. Keep in mind the current PLM architecture is mature, but they can be a dead-end in the future unless your trust is in a big vendor to evolve.

The future looks more remote and connected to manufacturing companies. The last ten months of COVID created a huge push for manufacturing companies to rethink their strategies for remote work, reducing supply chain risks and optimizing the work between companies, joint ventures, suppliers, and contractors. To realize the potential of distributed work, manufacturing companies will need to have new technologies combining new manufacturing methods, 3D printing, IoT, connected systems, and commerce, multi-tenant architecture can offer some unique value.

OpenBOM developed a mulit-tenant data management backbone for product information, collaboration, and intelligence.

OpenBOM unique multi-tenant data sharing architecture enables easy and instant data sharing between users, teams, and companies. Here is what says about OpenBOM data sharing capabilities one of the customers – agricultural robot manufacturer FF Robotics

“Something we didn’t anticipate was the ease of sharing the BOM with the rest of our team. We have a property for Make or Buy which we set in the Catalog. FF Robotics purchasing department gets the BOM and knows exactly what to do. We could have done it before but it demanded more work and sometimes it just didn’t get done or we made some mistakes.”

Conclusion

OpenBOM multi-tenant architecture provides a unique capability for companies to collaborate in their teams and connect and share data with contractors and suppliers. The data is flowing easily and becoming transparent for the business. OpenBOM is building advanced technology to help manufacturing companies make the right decisions when it comes to production planning, procurement, maintenance, and support.

Want to discuss how OpenBOM can help you to improve data sharing in your business, please contact us and we will be happy to set up a meeting with you to discuss.

OpenBOM provides free registration and an on-demand free 14-days trial to explore all system features and functions. REGISTER TODAY.

Best, Oleg @ openbom.com

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.