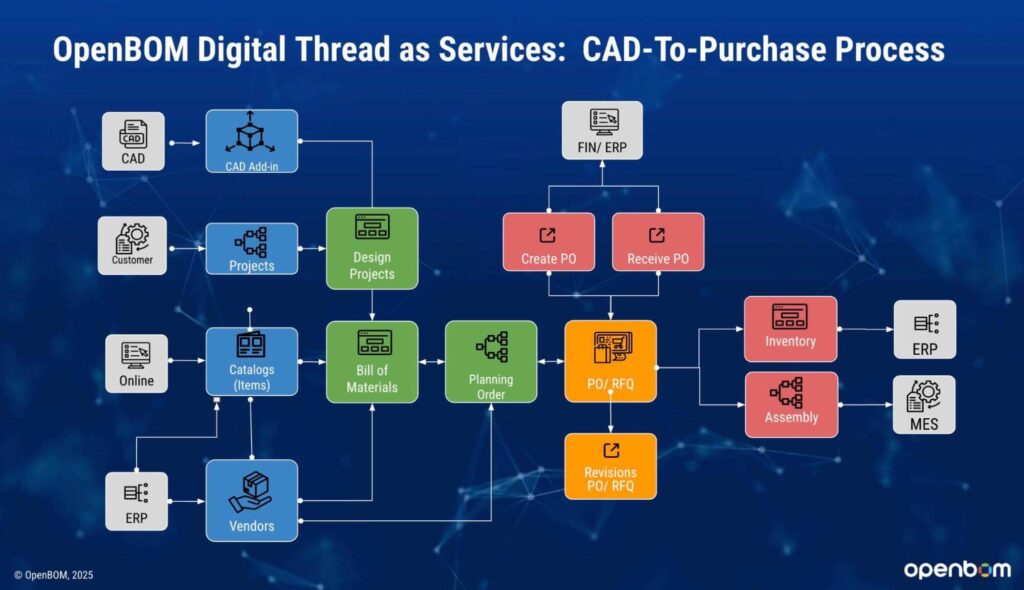

Last week, we hosted an exciting OpenBOM Live Demo, showcasing how OpenBOM Digital Thread as Services streamlines the CAD-to-Purchase process. Attendees saw firsthand how OpenBOM transforms disconnected engineering and procurement workflows into a seamless, automated digital experience.

If you missed the webinar, don’t worry! In this blog, we’ll recap the key takeaways and highlight how OpenBOM connects CAD data to purchase orders, ensuring accuracy, reducing errors, and improving efficiency across the product lifecycle.

What Does OpenBOM’s CAD-to-Purchase Solution Do?

OpenBOM eliminates the traditional, manual handoffs between engineering, BOM management, cost analysis, inventory tracking, and procurement. The webinar demonstrated how OpenBOM connects these processes into a single, traceable Digital Thread, ensuring that every stakeholder—from engineers to buyers—works with real-time, accurate data.

Here’s how OpenBOM organizes the CAD-to-Purchase process in five key steps:

1. Design Project Service – The Foundation of a Digital Thread

The process begins with the Design Project Service, which helps engineering teams manage design data from CAD systems like SolidWorks, Autodesk Fusion 360, and Onshape. OpenBOM automatically extracts structured product data from CAD, allowing teams to store, track, and manage revisions within a single, cloud-based system. This structured approach ensures real-time collaboration between engineering and procurement teams, eliminating data silos and enabling a seamless flow of information.

2. Item/BOM Management – Transforming Design into a Digital BOM

Once a product is designed, OpenBOM automatically creates and manages multi-level BOMs, transforming raw CAD data into a connected digital model. Unlike static spreadsheets, OpenBOM ensures that all BOM information remains synchronized with engineering changes. The system enables users to generate BOMs directly from CAD, enriching them with supplier details, cost data, and part specifications. Additionally, OpenBOM provides version control, allowing teams to manage alternates and substitutes effectively while ensuring that procurement teams always have access to the most accurate, up-to-date BOM information.

3. Cost Rollup and Analysis – Know Your Costs Before You Build

A major challenge in procurement is understanding product costs early in the design process. OpenBOM dynamically calculates total product cost based on real-time BOM data, ensuring that teams have a clear financial picture before moving into production. By analyzing cost breakdowns at the component, assembly, and supplier levels, OpenBOM allows procurement teams to optimize sourcing decisions and compare supplier pricing. This level of visibility ensures that companies stay within budget and avoid unexpected cost overruns.

4. Inventory Gap Analysis – Identifying Shortages Before Procurement

The next step in the process involves analyzing inventory levels to identify potential supply chain risks before issuing purchase orders. OpenBOM automatically cross-checks BOM requirements against available stock, comparing on-hand inventory with the parts required for production. If shortages are detected, OpenBOM highlights them in real time, allowing teams to identify alternative suppliers or make strategic adjustments to avoid production delays. By addressing inventory gaps before procurement begins, manufacturers can prevent last-minute surprises and ensure supply chain readiness.

5. Procurement (PO Management) – Automating the Ordering Process

Once BOMs and inventory have been analyzed, OpenBOM enables automated purchase order (PO) creation, reducing manual work and ensuring smooth procurement. The system generates POs directly from BOM data, automatically assigning vendors, calculating quantities, and factoring in real-time pricing. With built-in tracking capabilities, OpenBOM provides complete visibility into order status and integrates seamlessly with ERP systems, eliminating errors caused by manual data entry. By linking engineering data with procurement, OpenBOM ensures that ordering decisions align perfectly with product design intent, preventing costly misalignments.

Watch the Recording Video

If you missed the live session or want to revisit specific parts of the demonstration, you can watch the full webinar recording here:

🎥 Watch the Webinar Recording Now

This video will walk you through each step of the CAD-to-Procurement process, showcasing how OpenBOM’s Digital Thread as Services simplifies engineering, cost management, and ordering workflows.

Why This Matters: The Power of a Connected Digital Thread

The OpenBOM webinar demonstrated that managing product data across CAD, BOMs, inventory, and procurement doesn’t have to be a disconnected, manual process. With OpenBOM’s Digital Thread as Services, companies can eliminate manual errors by replacing spreadsheets with real-time data synchronization. Procurement decisions are no longer based on outdated information; instead, they are driven by live, accurate BOM data. By streamlining workflows, OpenBOM accelerates time to market while ensuring supply chain readiness.

Conclusion: Connect Engineering and Procurement

If you’re struggling with disconnected BOMs, manual procurement processes, or costly supply chain delays, OpenBOM provides a modern, digital-first solution.

📌 Did you miss the live webinar? Watch the recording here and see how OpenBOM helps companies move from CAD to Purchase Orders with a seamless Digital Thread.

📅 Want to experience OpenBOM in action? Schedule a demo today

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.