One size doesn’t fit all. TechClarity Ebook educates are about Engineering vs Supply Chain centric PLM systems.

Engineering-centric companies may value deeper capabilities like CAD integration from traditional solutions hosted on the cloud. Supply chain-centric companies likely favor agility and collaboration from newer cloud-native solutions. Today’s supply chain volatility and supplier-centric collaboration processes turn the “capability first” model on its head because the need for agility and supply chain collaboration are more important success drivers than traditional engineering-centric capabilities.

At OpenBOM we go to the next level by delivering the best of both worlds. Each manufacturing company thinks that its processes and organization of work is special. Manufacturing companies are indeed different, but usually, their differences can be classified based on manufacturing and other processes. In such a case, you can see companies focusing on engineering to order, configure to order, or build to stock. Each type brings specific needs and focus. Today, I want to talk about two approaches in the PLM systems – the engineering approach and the supply chain approach.

Traditional PLM systems were focused on engineering and had PDM roots. SaaS PLM systems are different. Cloud PLM (Saas) was coming from the very early days with the focus on web-based applications, connectivity, and ease of data access. However, these first web-based PLM systems were incapable of providing a competitive solution for engineering-oriented PLM.

So, we do have a conflict. Traditional PLM provides excellent CAD connectivity, but their tech is old and doesn’t allow to bring the power of the cloud and SaaS. At the same time, web-based PLM provides an opposite approach to share data and access information. This is a historical perspective of how PLM systems were built. Old on-premise systems are heavy on CAD and engineering and new web-based are opposite focusing on downstream solutions and supply chain.

How to connect both approaches? That was the idea when we started to build OpenBOM. The goal we took was to bring a system capable to start tightly connected to any CAD system and at the same time, being able to provide a platform for downstream and supply chain. OpenBOM approach eliminates the need to choose between them.

Here are 3 strong OpenBOM differentiators:

1- Immersive CAD integrations. OpenBOM has add-ins to all CAD systems (check more here). OpenBOM sophisticated plug-ins are capable of extracting any data, but it is not all. OpenBOM One-Click BOM for CAD gives you a unique experience of data extraction and bringing it all users. Bi-directional synchronization and visual BOM presentation make it pretty unique in the industry.

2- OpenBOM multi-tenant data management architecture and instant data sharing. OpenBOM provides a unique (a-la Google Doc) capability to share data. The data becomes available almost instantly. Team views give you a way to coordinate how information is shared and who is getting what.

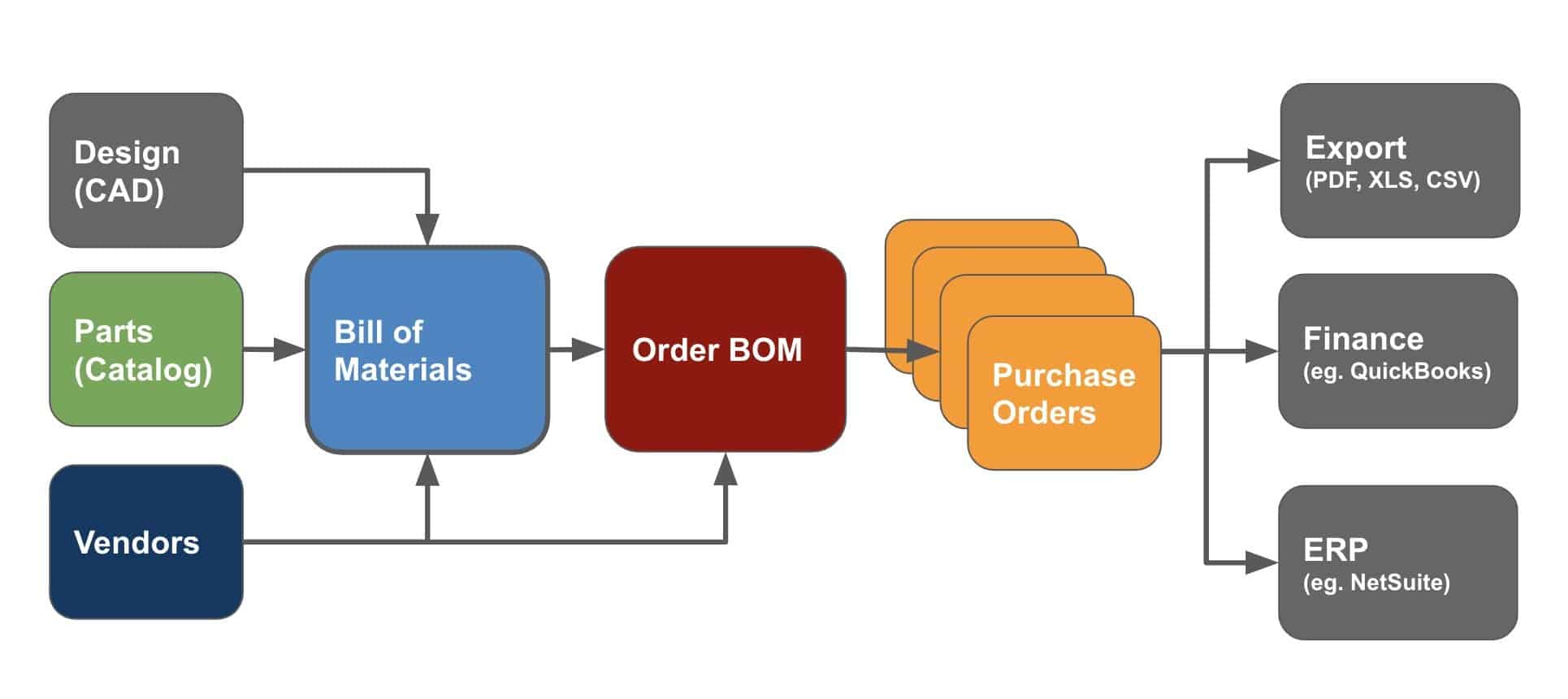

3- Design to Purchase the business process. At the heart of OpenBOM is a fully integrated business process, which enables customizable and configurable processes of purchasing and production planning. Order BOM is automatically created from Engineering BOM based on the planning parameters (eg. number of units to be ordered) and automatically calculates gaps in purchased assemblies, components, parts, and materials based on the inventory level managed in OpenBOM. The process can be seamlessly integrated to update inventory data upstream and purchase orders downstream to financial systems and ERPs.

Conclusion

OpenBOM gives you the best of both worlds – engineering and supply chain by organizing the data and automatically updates engineering and order BOM, generating RFQs and Purchase Orders for parts and materials. OpenBOM multi-tenant data management and real-time collaboration with simultaneous editing give you an amazing way to share data within your team as well as contractors and suppliers.

Check out what you can do with OpenBOM by registering and getting a free 14-days trial.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.