Autodesk Fusion360 is a great design tool used by hundreds of thousands of professionals engineers and hobbyists (makers, woodworkers, and any other people passionate about manufacturing and making stuff). Autodesk Fusion360 provides a wide range of tools from design to visualizations, simulations, and manufacturing. While Fusion 360 is great for individuals, we’ve been looking at how to extend the power of Fusion 360 to a team or a small company.

OpenBOM is a network-based platform, which is designed ground up to empower a team of people, helping manufacturing companies to work remotely, connecting manufacturers with their contractors and supply chains.

Since the early beginning of our journey with Autodesk, we’ve been thinking about how to connect the power of Fusion360 design, engineering, and simulation tools with the capabilities of OpenBOM to manage product data and the purchasing process. Think of a prototyping team, woodworkers, or small manufacturing company working on equipment, high-tech, electronic, or any other products. Fusion 360 gives great design capabilities, but lack the way to manage Parts, Vendors, Bill of Materials, Orders, and Purchasing process.

This is where the OpenBOM SaaS product is coming with a fully integrated with Autodesk Fusion 360 available via Autodesk App Store. You can download Fusion 360 add-in and start using OpenBOM immediately using free 14-days trial and later on moving into one of the available monthly or annual subscription plans. Check our pricing here. OpenBOM is also available free for education and non-commercial use.

In the following video, you can check OpenBOM’s recently released new add-in for Fusion 360, which includes a bi-directional data exchange with Fusion 360 as well as provides direct access to all OpenBOM data management and planning features.

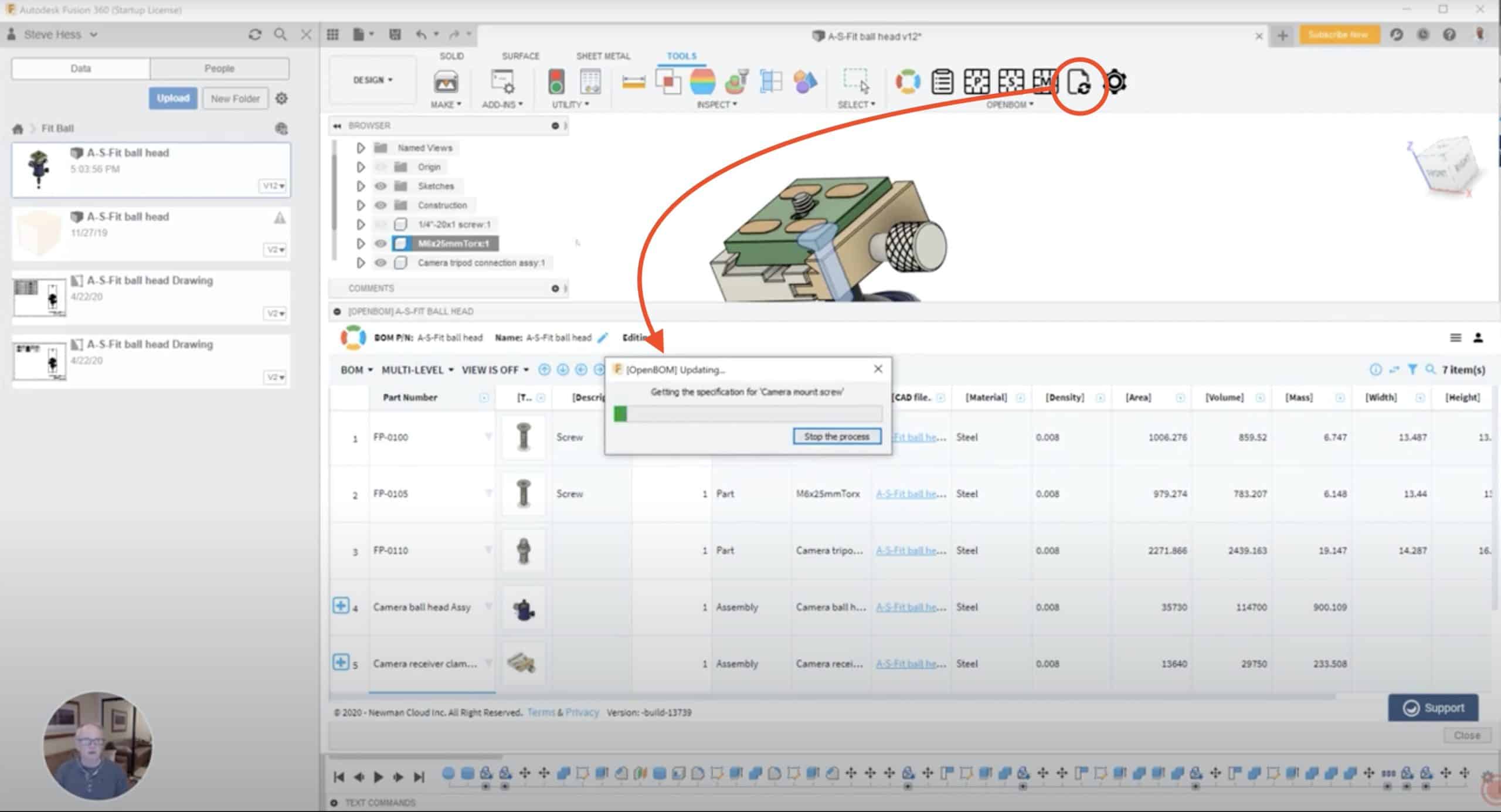

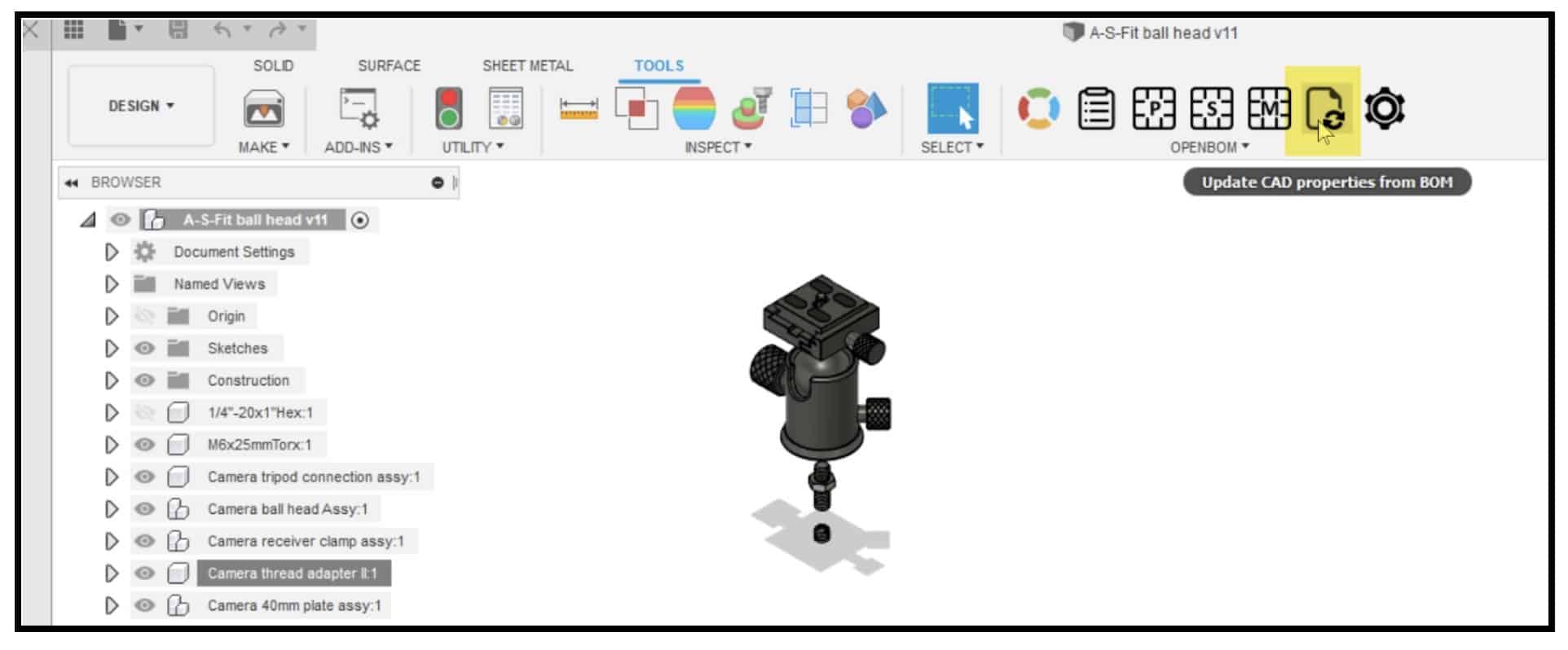

We all know how important Part Numbers, Names, and Descriptions are to a successful Bill of Materials. Well, now you can use OpenBOM to easily manage those properties then send the values back to Fusion. There is also a new icon on the toolbar to support sending property values from OpenBOM back to Fusion.

This video will take you through setting up your OpenBOM Catalog for automatic part number creation, creating a Fusion BOM, getting the next part number for each item, setting Description and Name, and finally saving it all back to your Fusion 360 model.

As one of our blog readers mentioned in his comments:

Jeff Bradway 5 days ago Very nice! You’ve just changed Fusion 360 from a great single designer or small team tool into a small-to-medium-sized business PLM tool! Now, when can I assign all my part numbers for a new assembly in one shot?

As you can see, the Product Life Cycle Management tool from OpenBOM is a great solution for startups and large organizations. If you also want to know how to organize product information using OpenBOM, you may check the examples provided in the above link.

I have great news for all of you. We are working on the next round of improvements for all OpenBOM CAD integrations to allow an automatic Part Number generation during the process of BOM and catalogs creation. The new Part Number generation will be included in OpenBOM One-Click BOM functionality very soon.

The integration with Fusion 360 is just a first step that allows you to connect the data in Autodesk Fusion 360 with the process of production planning and purchasing. The ultimate goal is to manage all parts, vendors, and purchase orders. You can learn more about it in OpenBOM documentation here. In one of the next articles, I will be talking more about how to make cost estimation and manage to purchase using OpenBOM.

Conclusion

OpenBOM vision is to provide simple yet powerful tools to engineers and manufacturing companies looking at how to get rid of Excel and streamline design, manufacturing planning, and procurement processes using unique SaaS technologies.

OpenBOM provides a robust and flexible mechanism to manage history, revisions, and changes. A new option to save baseline simplifies the way revisions can be controlled and automatically save revisions top-down in the assembly structure.

Meantime, you can check what OpenBOM does by registering for FREE and start a 14-days FREE professional trial just by clicking the button. If you already have an OpenBOM account, just click on the “Start Trial” button. No subscription, no annual commitment, and no credit card needed to try it out.

Best, Oleg @ openbom.com

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.