One of the questions I often get asked by our customers and prospects is related to the product release process. The terminology is not precise and can vary. Sometimes, it is a design release and sometimes, it is a BOM release.

What I found speaking to many engineers and companies is that there is a lot of confusion about the release process and what and when it should be done. And these questions are not necessarily coming from tools that are used by engineers and companies but from the fundamental understanding of the process.

In my article today, I want to start the conversation about the release process and how it can be organized as well as share some basic fundamentals that can help you understand how to organize the right process for your team or company.

I will bring examples of how OpenBOM online services can help you to manage the product lifecycle and release process.

Let’s start by clearing the confusion about multiple lifecycles

Let me start with the definition of multiple lifecycle stages. Even in a small team of companies, you’re involved in multiple lifecycles. Here are some of them- (1) design; (2) engineering (3) production manufacturing, and (4) support.

Misunderstanding of fundamental elements and differences between these lifecycles can create major confusion in the way you organize the processes. Here is an example. Earlier this week someone asked me if the change of Solidworks part will trigger an ECO to be open with the assembly.

It is a great example to show that multiple lifecycles are happening simultaneously and independently. Changes in the design might not trigger any changes in the BOM until the team reached a certain maturity level. Multiple design variations can happen before BOM will be created and released. At the same time, BOM reversion (release) doesn’t mean anything about the design change process.

It is important to differentiate between multiple lifecycles. They are intertwined and connected, but at the same time, they are independent of each and allow your team to work in a connected way.

In my article today, I will speak about two major lifecycle processes – (1) Design lifecycle; (2) Engineering BOM and Change Management. (PS. I will not cover EBOM to MBOM or, so-called, Engineering to the Manufacturing process – it will be covered separately).

Design Lifecycle

The foundation of design lifecycle management is to manage design artifacts, their lifecycle, and changes. A typical design lifecycle management process includes the ability to organize design data management, version control, and collaboration. OpenBOM Design Projects is an online service that provides you with such capabilities.

Engineers are working with CAD design and performing changes. OpenBOM Design Project services allow flexible file management using a smart sync function to automatically sync files between local folders and cloud storage. A special “File Explorer Publish” function allows to make files available read-only in full sync to all users (this option is very good for sharing libraries that don’t require editing). ,

OpenBOM provides both access files via synced local storage and web browser dashboard user experience. Check out more about OpenBOM Design Project Documentation.

Items Lifecycle and Change Management Process

The foundation of the Item lifecycle includes a flexible reference-instance product model, which includes items and a Bill of Materials. Items and BOMs support a revision mechanism that allows for the management of the history of changes as well as the creation of an immutable snapshot of both Items and BOMs to preserve the history of revisions.

It is important to notice Item information includes the data about all item characteristics, including attached spec files, documents, files, and Bill of Materials. The last one is presented by an individual object, but it is tightly connected to an Item (managed in OpenBOM catalogs).

There are three fundamental mechanisms in OpenBOM to support Items and the BOM lifecycle.

- Automatic change history capture (items/BOMs). Each time you make a change, OpenBOM captures what was changed. You don’t need to worry about that.

- Revision mechanism. It is an on-demand user-driven process that captures data about an item and BOM and puts it in an immutable status.

- Change Request and Approval. This mechanism allows performing validation and sign-off for an item or BOM ***before*** it will be released.

Change OpenBOM change management training for more information.

OpenBOM Services and Functions

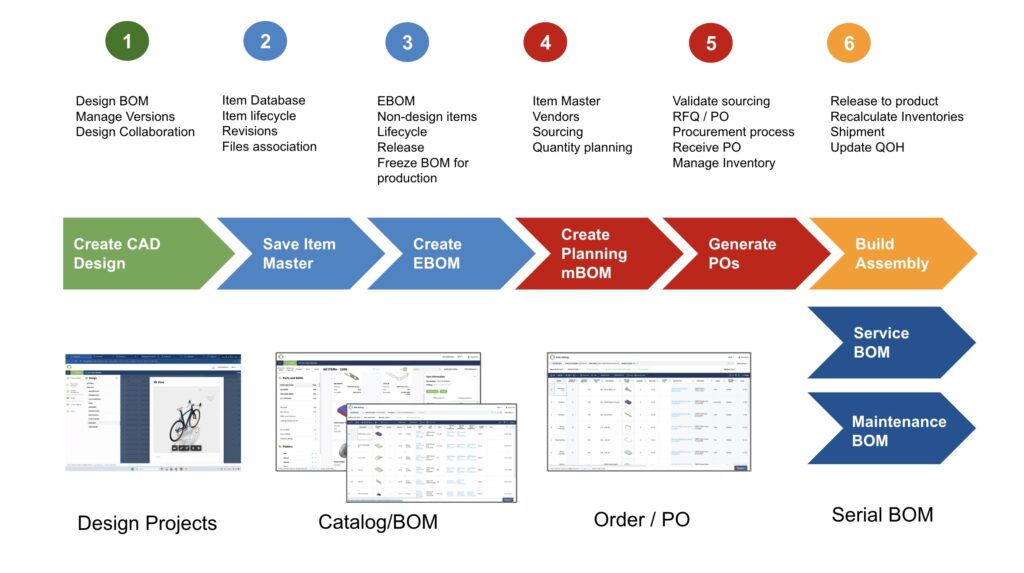

The following diagram shows you the services and functions of OpenBOM to support the product lifecycle. It covers a wider range of product lifecycle including planning, building, and services. I will talk about them more in my upcoming articles.

Stay tuned for the video tomorrow about PDM services, Items, and BOM Management.

Conclusion

Product release is a complex process, which includes multiple steps and connects multiple people and activities together. OpenBOM services allow you to perform a granular set of activities to manage design files, and design changes (versions), to perform a handover of data to create items and BOMs as well as to manage item lifecycle including maturity levels, revisions, change management processes and eventually to release product to manufacturing.

A specific process for each company can be different. The flexibility of the OpenBOM platform is a key to allowing for the set up of a custom data model, configuring a change process, and, at the same time, providing basic functionality out of the box. However, we are not done – OpenBOM is in ongoing development and you will see new features and functionality coming later in 2022 and next year.

REGISTER FOR FREE and start a free 14-day trial to check out how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.