Manufacturing companies are under constant pressure to bring new products to market faster and at a lower cost. At the same time, they must ensure that products are reliable and meet customer demands. This can be a challenge, especially for companies with limited resources.

Product development is a complex process that involves many different stakeholders and moving parts. To ensure that products are developed efficiently and meet customer needs, it’s essential to have a streamlined process in place.

OpenBOM can help streamline product development and lifecycle management, making it easier to manage complex projects and stay competitive. OpenBOM is a cloud-based product development and lifecycle management platform that makes it easy to track all aspects of product development, from initial design, including managing files, creating and managing multiple Bill of Materials, controlling change processes, and taking the process directly to purchasing and production planning. With OpenBOM, you can manage your product data in one central location, making collaboration between team members easier than ever. Plus, OpenBOM is integrated with leading design tools like SolidWorks and Autodesk Inventor, so you can easily create and share BOMs (Bill of Materials) with your team.

Let me share a breakdown of the process of how OpenBOM can help your company including mechanical designers, electrical and electronic engineers, purchasing and production planners, managers as well as contractors and suppliers to work together and use OpenBOM as a distributed PLM platform serving everyone.

What is OpenBOM and what does it do?

OpenBOM is an online platform that manages information about products, including information about items, Bill of materials, and files as well as file versions, item revisions, and BOM revisions. OpenBOM provides full traceability of the information and changes.

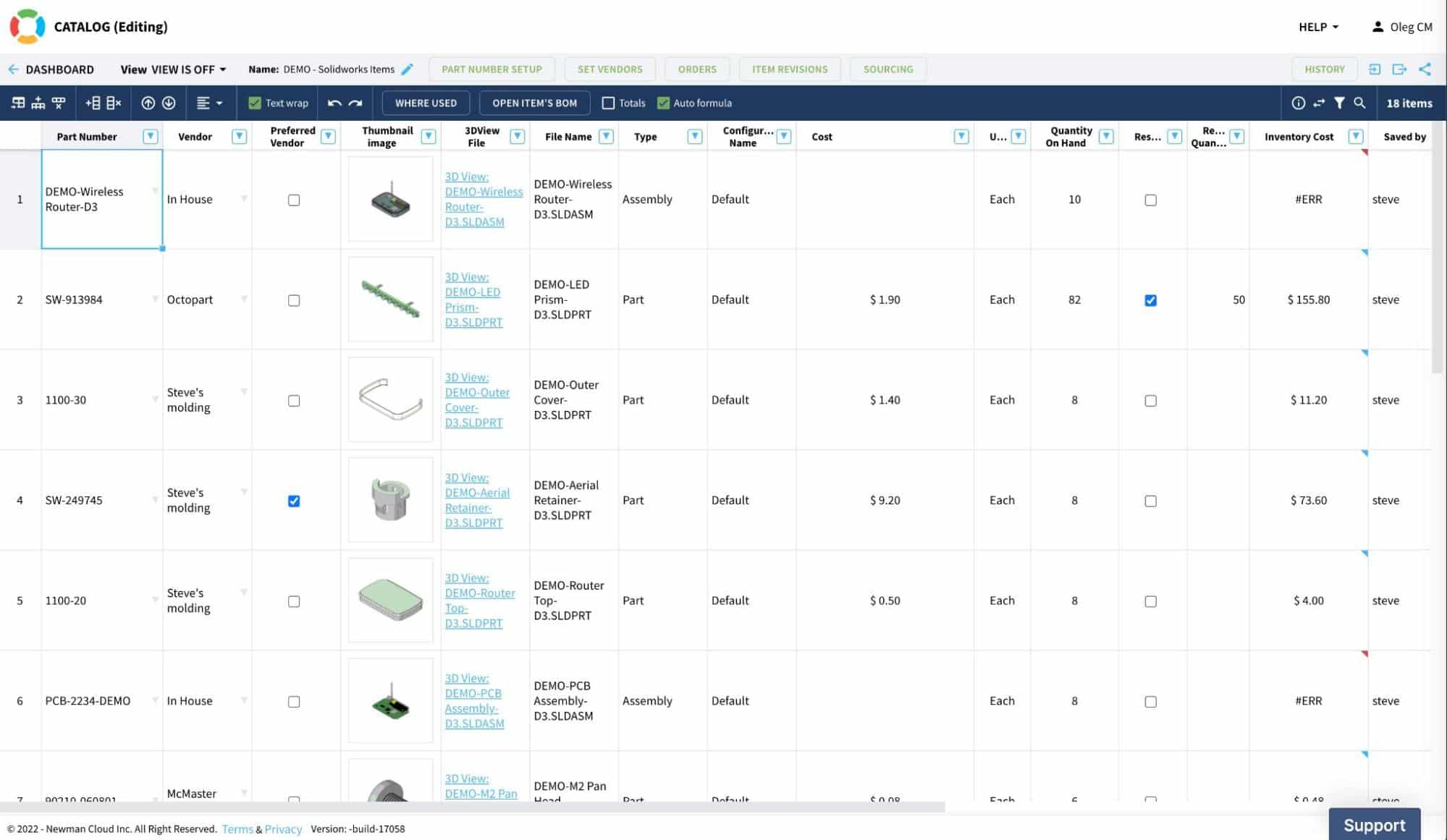

The foundation of the OpenBOM data management system is a distributed flexible data management system allowing for the management of catalogs with items. An item can be a simple part or complex assemblies. In the second case, OpenBOM will manage a BOM associated with the item. Item can have revisions. If BOM is associated with an item, OpenBOM will manage BOM revisions as well.

OpenBOM data model is flexible and you can define a set of attributes (properties) associated with each item. Different item types will be stored in multiple catalogs and have a different sets of attributes. OpenBOM supports multiple property types and allows you to attach multiple files to each item.

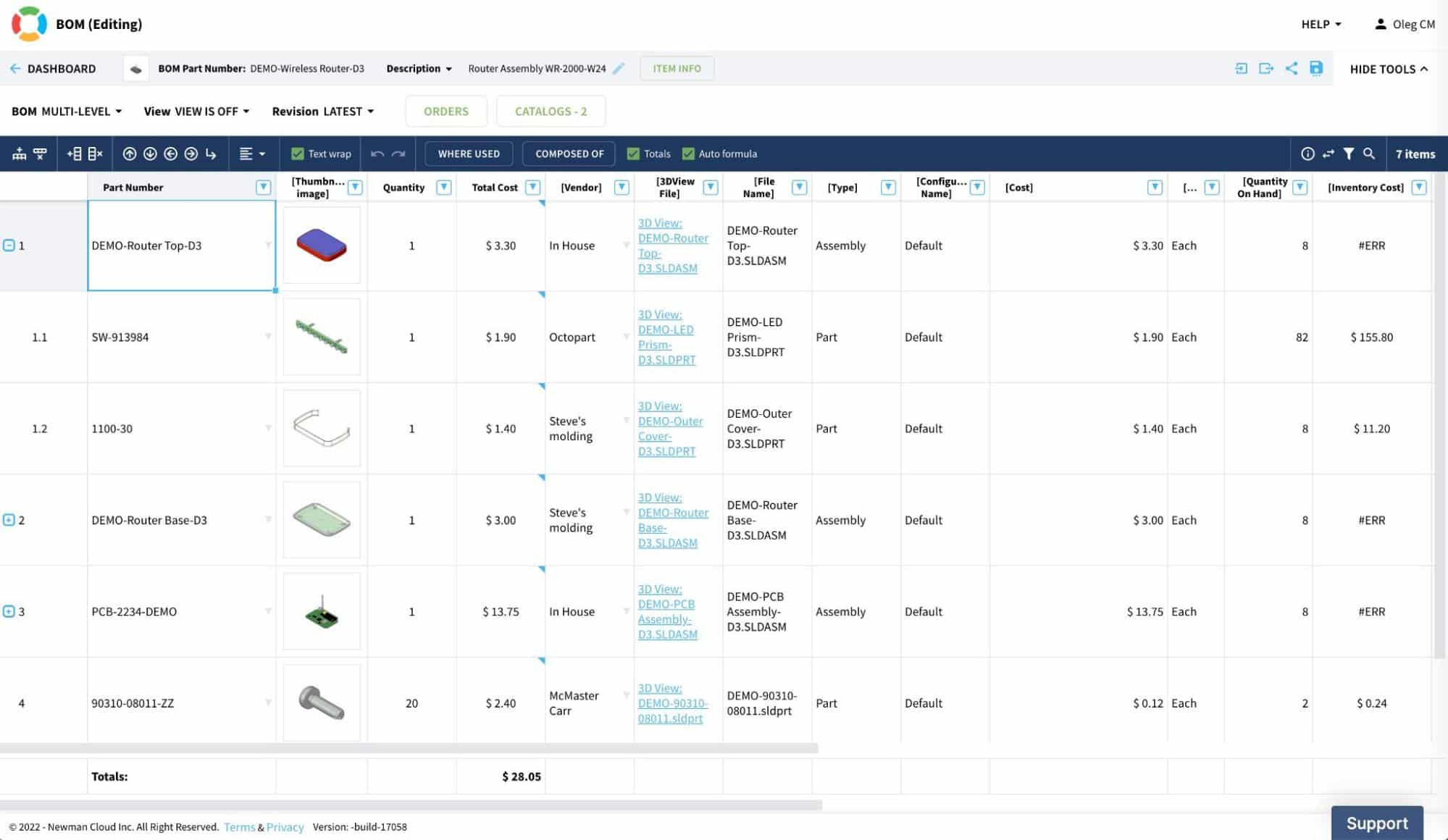

OpenBOM supports a flexible mechanism for Bill of Materials editing and management including multi-level BOM management, allowing for the creation of a multi-disciplinary BOM combined with mechanical, electronic, and software components. as well as to quickly switch between single, multi-level and flattened structures. Also, OpenBOM supports an easy way to define formulas to perform calculations and rollups.

Beyond core data management capabilities, OpenBOM can help you to manage the following information and processes:

- Vendors

- Inventories

- EBOM and MBOM

- RFQs and Purchase Orders

OpenBOM is a flexible yet powerful data management platform available globally online helping to manage data and processes.

How OpenBOM helps streamline product development

Modern product lifecycle management helps companies to manage product development, to connect teams, contractors, and suppliers, and provide a reliable PLM platform for data sharing and processes. The following three elements of OpenBOM turn it into a super-efficient platform to help the product development and manufacturing team to deliver results faster and with a higher level of predictability: (1) Collaboration; (2) Integrations; (3) Change management. Let’s speak about each of them.

Collaboration is the heart of OpenBOM. With a patented BOM collaboration mechanism, OpenBOM allows the instant sharing of data and supports simultaneous data editing by multiple people. The data can be shared with the members of your team as well as to support collaboration and data sharing with contractors and suppliers. Seamless import/export can help you deliver information to people that have no access to OpenBOM online.

OpenBOM is integrated with many CAD and other engineering systems. Check the full list here. By doing so, OpenBOM allows you to seamlessly capture information (eg from CAD systems such as Solidworks), and keep data in sync between CAD and EBOM. Eliminating manual data reconciliation speed up the process and eliminate potential mistakes.

Change Management is an integrated mechanism in OpenBOM capable to create and support the entire product lifecycle change management process including revisions, change requests, change orders, and the approval process.

OpenBOM PLM is an online and cloud-native platform. It is available via the browser, doesn’t require installation (except if you install CAD integrations), is updated automatically, and is available globally in many countries.

The benefits of using OpenBOM for lifecycle management

Here are five top benefits of using OpenBOM to support your product lifecycle management (PLM) and provide a foundation for your product development team.

- Single source of truth: A single repository for all product information

- Full product record and change traceability for changes, revisions, etc.

- Easy cost assessment and analysis of multiple suppliers

- Seamless data handover from design to engineering (CAD to BOM)

- Connecting Design and Purchasing processes

OpenBOM provides a powerful set of functions with unmatched ROI in the industry. Because of the flexible data model and powerful data sharing and collaboration, OpenBOM is an ideal platform for modern distributed companies and a great example of modern PLM software.

How to get started with OpenBOM

OpenBOM is very easy to start. Unlike many other PLM software, you can REGISTER FOR FREE and start using it right away by starting a free 14-days trial. OpenBOM pricing is available online and can help you to start a subscription and choose an online training course or dedicated onboarding process. We can get you on OpenBOM in a matter of days or a few weeks. If you have questions, contact our support.

Case studies of how OpenBOM has helped companies achieve success

Let OpenBOM customer speak about OpenBOM. OpenBOM helps thousands of engineers and manufacturing companies get rid of Excel and establish a robust system to manage product information and related processes. Here are two sources of customer stories you can check out.

Conclusion

OpenBOM is a robust online platform to support product development and lifecycle process. It is integrated with multiple existing engineering systems (eg. SolidWorks and other MCADs and ECADs), provides a flexible data management platform to manage product data including revisions and changes as well as provides open and collaborative mechanisms to share data upstream and downstream throughout the manufacturing processes.

REGISTER FOR FREE to check out what OpenBOM can do for you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.