In manufacturing, the importance of sourcing high-quality custom parts cannot be overstated. Manufacturers rely on these specialized components to build products that meet strict specifications, perform optimally, and satisfy customer demands. Oftentimes, these parts have an effect on the final assembly and a minor defect can result in a product failing its quality tests.

In the supply chain, there are two types of parts that are purchased, custom parts and off-the-shelf parts. With the simplicity of using distributors, such as Digikey or McMaster Carr, off-the-shelf components have become more straightforward. Even if you are looking to cost down these parts, you can still refer to a supplier with the manufacturing part number (MPN) from a large distributor and they can re-create that part.

The issue is procuring custom parts, especially for prototypes, first-time builds, or products that are engineering made to order.

In this blog, we will look at why procuring custom parts is more complex and the different options you can use to procure these parts.

Why is Procuring Custom Parts More Difficult

There is a debate about whether or not you should use a custom part when an off-the-shelf part would do the trick. Oftentimes, there is a reason off-the-shelf parts will not work and a custom part needs to be designed. However, these custom parts add a layer of complexity to the supply chain.

With these complexities, there are added challenges when compared to purchasing off-the-shelf components. Here are some of the challenges with procuring custom parts as opposed to off-the-shelf components:

Engineering Complexity

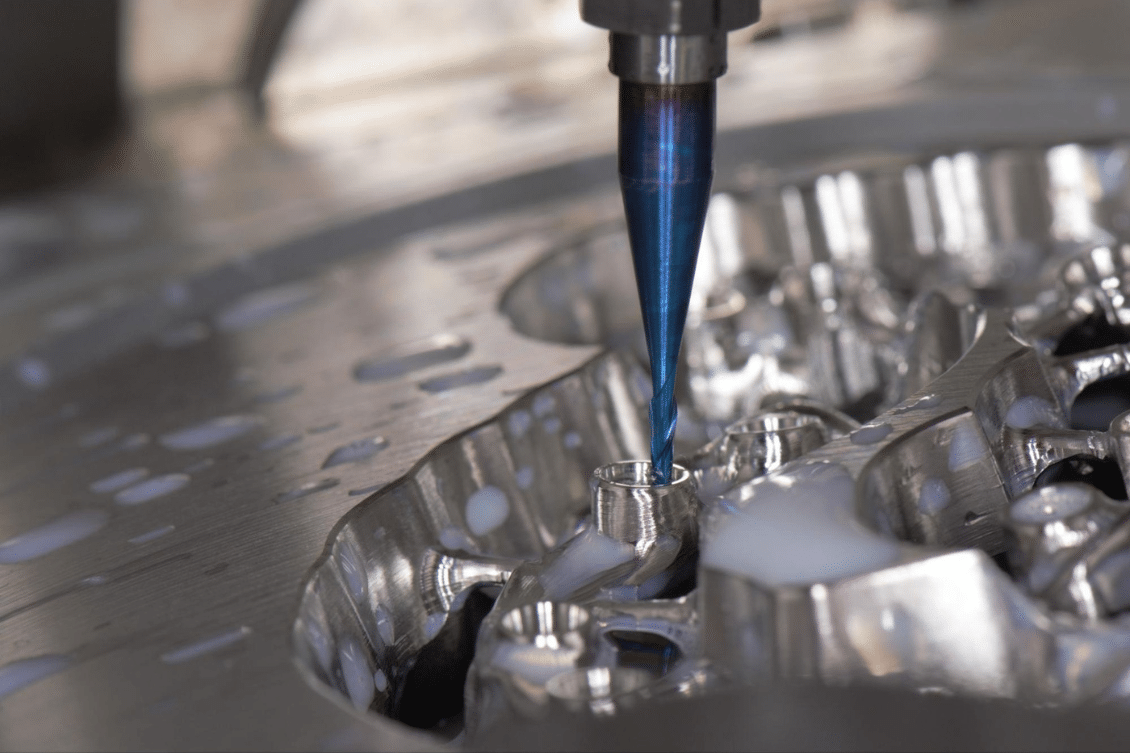

Custom parts are specifically designed and engineered to meet unique specifications and requirements. This complexity often involves intricate designs, specialized materials, and precise manufacturing processes. As a result, finding suppliers capable of producing custom parts that adhere to these specifications can be more difficult compared to sourcing readily available off-the-shelf parts. Also, communicating the part information to suppliers and making sure they understand the product specifications creates further challenges.

Limited Supplier Options

When searching for custom parts, the pool of suppliers may be smaller compared to those offering off-the-shelf parts. Custom parts often require specialized expertise and equipment, limiting the number of suppliers capable of manufacturing them. This limited supplier base can make the procurement process more challenging as finding the right supplier who can meet your requirements becomes a crucial task. Also, oftentimes, with custom parts, there needs to be a round of design for manufacturing (DFM) to optimize the part for production.

Longer Lead Times

Custom parts typically involve a more involved production process compared to mass-produced off-the-shelf parts. Also, with off-the-shelf components, you have multiple suppliers building the same component and you can quickly see who can provide the fastest lead time for a specific order.

The manufacturing of custom parts often requires additional steps such as design validation, prototyping, and tooling development. These extra processes can result in longer lead times for custom part production, which may impact production schedules and time-to-market for the final product.

For off-the-shelf components, suppliers are often willing to hold inventory. There is less risk because there is a large customer base that will purchase that part. Therefore, the lead times are quick. However, with custom parts, the supply might not be willing to hold too much inventory because there is only one buyer. That supplier can’t sell the custom part to anyone else, only the manufacturer who designed it.

Higher Costs

Custom parts are usually more expensive than off-the-shelf parts. The production of custom parts often involves additional setup costs, specialized tooling, and low-volume production runs. These factors contribute to higher unit costs for custom parts. It’s easier for a factory to reach economies of scale with an off-the-shelf component because of a larger demand.

Quality Assurance and Testing

As custom parts are specifically designed to fit unique requirements, ensuring their quality and functionality becomes crucial. This may involve additional quality assurance measures, testing, and validation processes to guarantee the performance and reliability of the custom parts. These extra steps can add complexity to the procurement process and require close collaboration with suppliers to ensure compliance with quality standards.

How Should I Purchase Custom Parts?

When it comes to purchasing custom parts, there are a few steps in the initial phase that do not change. However, with the rise of on-demand manufacturers, such as Xometry, Hubs, Fictiv, and many more the steps to actually bring these custom parts to market have changed.

The first step to sourcing your custom parts is the same no matter what. But after the original step, the process can change.

Define your Requirements

The first step is to always define your specifications. Whoever will make your product will need to understand the specs. These include:

- Material

- Finish

- Color

- Tolerances

- Function

Find Suppliers

Finding suppliers that have custom parts is not easy, especially if you do not have relationships with any suppliers. Evaluating suppliers has always been difficult for manufacturers and the people who are tasked with finding suppliers might not have as good of an understanding of the specs as the engineers.

This is where the value of on-demand manufacturers comes in. You don’t need to spend any more time evaluating suppliers and communicating with them. You just input your drawings and specification and you’ll have your part.

Proceeding with this route is not always ideal though. You sacrifice a few things, supply chain transparency and costs for example.

However, depending on where you are in the development or production process and your size, you might be ok with sacrificing both of these for convenience.

Request for Quotation

After you have found suppliers, you’ll need to request a quote from them. During the request for quotation (RFQ) process, you provide them details about your part that covers all of the requirements defined above.

In return, your supplier will provide you with a quote for your custom part that also includes lead time, tooling, sampling, etc…

Sampling

Once you accept the quote from one supplier, you usually want to test them out. The best way to test their capabilities is to have them make you a sample. While the prototype process is usually going to differ from that in production, it will also give you a better understanding of how their work and the quality of their work.

Negotiation

These negotiations should revolve around a few things and not just costs. Discuss with your supplier the following:

- Lead time

- Holding inventory

- Payment terms

- Quality

Everything is negotiable with your supplier and they are usually willing to work with some of your requirements. Based on this, the sample, and a few other aspects, you will decide who to work with.

Place the Order

The last step of the process is to place the order with your supplier. Depending on the part you are making, you might need to place the PO for tooling before mass production.

How to Manage all of this?

Managing all of this data is not easy. You have data coming in from engineers about the parts and you have quotes coming in from the supply chain. Also, if COVID has taught us anything, it’s the importance of a diverse supply chain. Therefore, you don’t just have a quote from one supplier. You have quotes from multiple vendors from around the world for the same item.

Historically, manufacturers have stored these quotes in Excel and locked them away in a folder. However, finding these and having instant access to them is a pain. Usually, manufacturers just choose the cheapest quote and then scramble to find old emails when the supplier increased their price, can’t meet your demand, or went out of business.

With the evolution of digital transformation, manufacturers now have the option to store all of this product information in a single location. As a result, you are able to make decisions much faster.

What Can you do Today?

As we know, managing all of the product data for your product is hard. Having all of this information readily available for not just you but also your team and suppliers is vital for your success.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store, and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

By, Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.