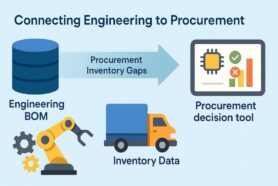

In the modern manufacturing and supply chain management environment, streamlining processes from engineering to procurement is vital. To support customer demand, companies need to improve their processes. Efficient data organization and effective supply chain management ensure that product development flows smoothly from initial design to final production, enhancing productivity and reducing errors. The foundation of the process is product data management, product lifecycle management, managing inventory organizing raw materials, and supply chains.

The Challenge of Connecting Engineering and Procurement Processes

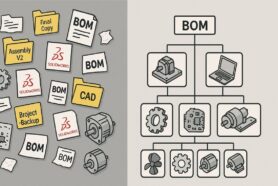

The most simple description of every manufacturing process includes three steps – (1) design your product; (2) make, outsource, and purchase components; (3) make an assembly. While a lot is done about the first one – design, engineering, simulation, etc. the process to help manufacturing companies source parts didn’t change much for decades and relies on spreadsheets and email. It causes delays and causes costly mistakes. Management is looking at cost optimization and risk mitigation and these manual spreadsheet-based disconnected processes can provide very little help. At the same time, supply chain managers literally have nothing more than working with ancient spreadsheets to chasing suppliers and contractors. The question of how to connect the product development process to the procurement process and overall business processes in an organization is a key factor to success.

While you might think the problem is typical for small and medium size organizations without proper IT support and do-it-your-self sourcing and ordering processes, we found a similar problem exists for enterprise companies, including Fortune 500 manufacturers. It was amazing to see how NPD and prototype development processes of large enterprises, medical device manufacturers, industrial equipment makers, and high-tech product manufacturers rely on spreadsheets that are very similar to those of small companies.

OpenBOM Agile NPD

At OpenBOM, we’ve been thinking about how to help a wide range of manufacturing companies streamline their sourcing process by improving data accuracy, optimizing the ordering process, and automating the quote (RFQ) process.

The key differentiation of OpenBOM is an agile process helping to optimize design, BOM, purchase, and assembly steps.

In my article today, I want to give you more details on how you can streamline your RFQ process using OpenBOM.

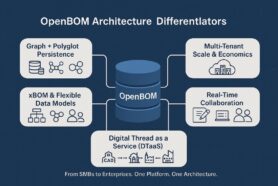

OpenBOM: A Comprehensive Data Management Solution

The foundation of OpenBOM is a flexible data management platform. OpenBOM offers a flexible and robust data management environment designed to meet the needs of a wide range of companies starting from SMB/SME manufacturing businesses and NPD and prototyping teams in enterprise organizations. It relies on modern SaaS solutions that are instantly available to any company (click on Register for Free on the top of the page).

Here are some of the key features that make OpenBOM different from many others:

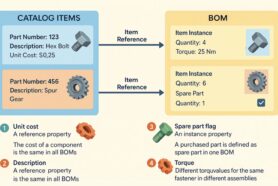

- Organizing Product Information (BOM): OpenBOM efficiently organizes Bill of Materials (BOM), ensuring that all product data is accurately captured and maintained.

- Automatic Data Capture via CAD Integrations: With multiple CAD integrations, OpenBOM automatically captures engineering data, reducing manual entry errors and ensuring data consistency.

- Vendor, Inventory, and Order Management: OpenBOM manages vendors, inventories, and orders, providing a centralized platform to streamline procurement processes.

- Integrated New Product Development (NPD) Process Support: OpenBOM supports the entire NPD process, offering tools to manage the product lifecycle from concept to production seamlessly.

The picture below gives you an idea of how the integrated NPD process is organized.

5 Steps to Organize Your RFQ Process with Suppliers Using OpenBOM

Organizing your Request for Quote (RFQ) process with suppliers can be streamlined in a few simple steps:

- Register Your Account and Install CAD Integrations: Start by registering your OpenBOM account and installing the necessary integrations for your preferred CAD systems. This ensures that your engineering data is automatically captured and integrated into your BOMs.

- Import Vendor Lists: Import lists of suppliers you are purchasing from into OpenBOM. This creates a centralized vendor database that can be easily accessed and managed.

- Capture a BOM for Your Product: Create and capture a BOM for the product you plan to build. This BOM serves as the foundation for your RFQ process, detailing all the components and materials needed.

- Create an Order and Assign Vendors: Generate an order for the required materials and assign vendors from your imported lists. This step ensures that you have all the necessary supplier information linked to your order.

- Generate RFQs and Send to Suppliers: With the order and vendor information in place, generate RFQs and send them to your suppliers. OpenBOM allows you to customize these RFQs, adding specific attributes and details relevant to your supplier relationships.

Customization and Flexibility

Customization and flexibility are critical in supplier relationships. OpenBOM allows you to optimize and customize the process by adding attributes to catalog items, BOMs, and orders. This flexibility ensures that you can tailor the RFQ process to meet the specific needs of your supplier relationships, enhancing communication and collaboration.

Conclusion

In today’s manufacturing environment, managing agile methods of working with suppliers is crucial. OpenBOM helps manufacturing companies and engineering teams streamline the New Product Development (NPD) process by capturing data and facilitating agile collaboration. With its unique integrations and customization options, OpenBOM optimizes sourcing processes, reduces costs, focuses on sustainability, and mitigates supply chain risks.

If you’re still cranking Excels to export data from CAD systems (MCAD and ECAD) and then spend hours organizing RFQ for suppliers, it is an opportunity to check how OpenBOM can help you. Embrace OpenBOM to enhance your procurement processes and drive efficiency in your manufacturing operations.

REGISTER FOR FREE and check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.