Most manufacturers, no matter their size, will not have a competitive advantage with everything. These manufacturers usually end up partnering with other companies that strive where they are weak. One area where manufacturers usually seek support is during design for manufacturing (DFM). And companies who are usually able to provide support with DFM is their production partner.

Before we look into who can support you with DFM, let’s first understand DFM better. The goal of DFM is to optimize the product for production. If done correctly, the DFM steps are started in pre-production. After DFM is completed, you can start tooling, testing, and production.

Therefore, before you start DFM, you have already chosen the contract manufacturer (CM) you will work with. When evaluating suppliers, it’s important that they can help you not just with production but also with any pre-production steps as well, such as DFM.

Can your Supplier Support you with DFM?

DFM is a small part of the overall new product introduction (NPI) process. There is not one company that will take you from the first part of the NPI steps all the way to production. The company you contracted to get to the prototype phase might not be the ideal partner to take you from prototypes to production.

The reason for this is that the company that designed the product for prototypes will not be the one who makes it in production.

During DFM, you will be focusing on improving a few areas. The areas you want to improve should make it so you mass produce your product as cost-effectively as possible while also being built to spec. Here are the areas you focus on:

Individual Parts/Items

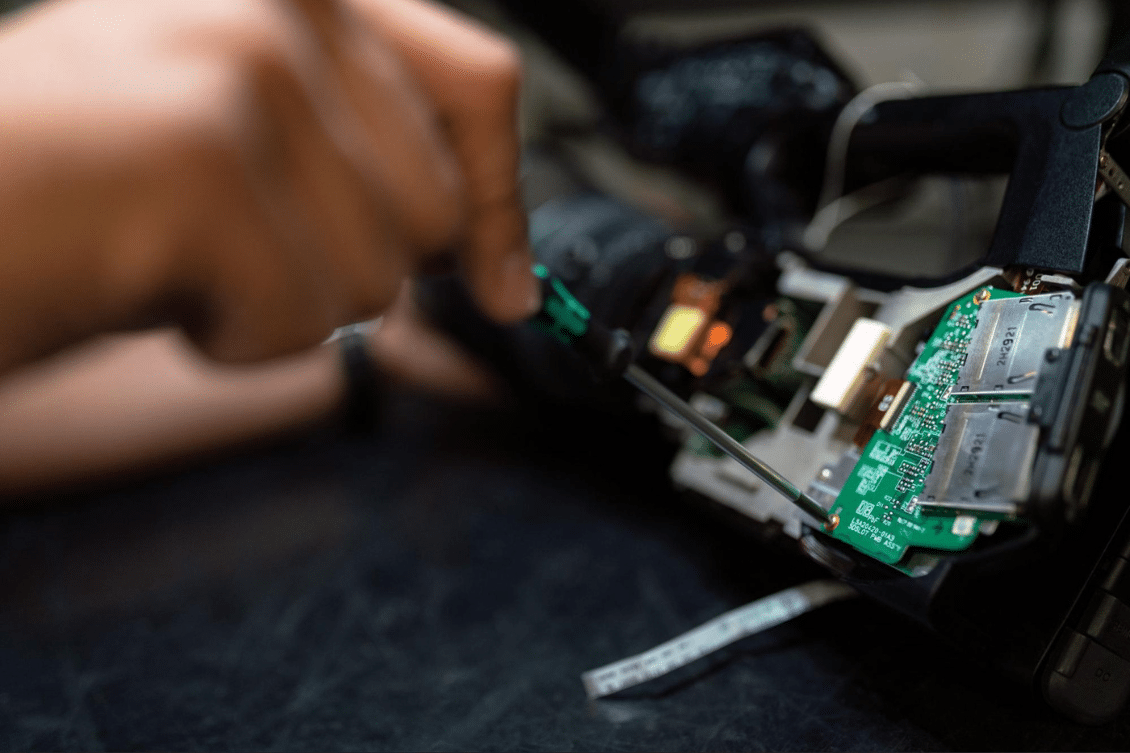

The process of creating prototypes is most likely not ideal for production. Therefore, you will need to optimize the fabrication of each part. Some of these are quite simple, such as replacing 3D printing with injection molding. Others are a bit more complex. You might need to look at combining parts or eliminating other parts.

During this process, your CM should help you with the following:

- Define the tolerances for each part. Also, confirm that the tolerances set by their client are attainable.

- How to cost down the more expensive parts?

- What is the correct sized machine in order to make the part? A smaller machine can produce a part with defects.

- Are there alternatives for expensive and long lead time items?

Sub-Assembly & Final Assembly

At this stage, your CM will be able to work on the flow so you can quickly and efficiently build each sub-assembly and bring in all sub-assemblies and parts for the final assembly. Your CM will need to understand your forecasts so they can plan the appropriate amount of operators and labor to build your product.

During the sub-assembly and assembly stage of DFM, your CM can help you with the following:

- How should each part be assembled?

- Can all the hardware pieces be assembled using the same part or can you limit the number of unique hardware pieces? This decreases the number of tools needed.

- Which jigs are needed to ensure consistency with all builds?

- Are there any design changes you can create to?

Off the Shelf Components

Not every single item you use will need to be custom. It’s preferred if you can use parts that are readily available, assuming the lead time is not too long. For these parts, your CM will be able to answer these questions to get you through DFM.

- Are the components readily available?

- What are high-risk items with long lead times?

- Can you find any other options from local distributors or suppliers?

Tooling

Purchasing tools for production usually adds up. However, you don’t want to be cheap. The quality of the tools is what will give your parts the consistency they need for mass production. Usually, a CM will need to re-design parts, especially for tooling. This is an important step because you don’t want to invest in tools and then find out the end result of the parts is not accepted.

Your CM can help you with the following during the tooling stage:

- Should you have multiple parts in the same tool – a family tool?

- Do you need to save some space for textures on the tool?

- Know the tolerance so they can design the tool to meet the specifications.

No matter the steps of DFM, your CM will be able to provide you with support. If your CM is unable to provide you with support during these steps then perhaps they are not the correct partner for you.

Enable Collaboration with your Supplier

Unfortunately, you can’t just expect your CM to start with DFM right away. You need to communicate with them what your goals are. Without this communication then you will not have any improvements.

Proper communication with your supplier is the first step in enabling collaboration with your supplier.

In order to enable DFM with your supplier, you need three things.

A smooth Transition of Data

The first part of DFM is sharing your product information with your supplier. While an email with folders and excels are familiar they are not the appropriate way to send data today. Think of digitizing your BOM.

Providing your supplier with a digital BOM will provide the following:

- Keeps everyone on the same BOM. Important for collaboration.

- Stores all changes and revisions.

- Sets a workflow for change requests.

A smooth transition of data is no longer a data dump. It’s setting yourself up to communicate on a single platform that both parties can use.

Set Priorities

Unfortunately, no matter how large your size is, you can’t achieve everything at one time. You will need to set priorities.

With setting priorities, you will need to understand how each part affects other parts. For example, when setting priorities, make sure the last priority will not change something that was optimized during a previous phase. If you do then you’ll be going back and forth making changes for quite some time. Unfortunately, this happens a good amount of times, especially in the startup world.

Setting priories with your supplier will help them identify where they should be starting so no changes will negatively affect a part that was already changed.

Provide a Target Price

Many manufacturers are not willing to provide a target price because they feel the supplier can extend profits to meet the target price if the costs are lower.

The goal of the target price is to have a direction during DFM. If you have no financial direction during DFM then what are you trying to achieve?

Defining the target price will also show transparency in what you are able to build. If you are asking for a low price then you might need to sacrifice some quality. Are you willing to do this? These are questions your CM can walk you through. However, not being transparent with the price will hinder collaboration when it comes to DFM.

What can you do today?

If you are looking to transition from prototypes to mass production then you need to streamline the DFM steps. One of the best ways to streamline this process is by bringing in a partner that will build your product. And in order to get the best out of this partner, you will need to enable collaboration. This is your starting point for digital transformation.

The digital transformation will help you to transform your processes to use digital technologies to keep all of your product data together, manage your revisions, and manage an ECR/ECO process. To have a centralized platform that connects your team with your contract manufacturer is extremely important to set up modern digital processes to save time and money.

OpenBOM is a cloud-based PDM & PLM platform to manage your engineering and manufacturing data. Companies from startups to Fortune 500s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, share data instantly, or collaborate with contractors and suppliers. contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.