The manufacturing industry is rapidly evolving, with constant changes in the ways products are designed, produced, and brought to market. Efficient management of product data and workflows is becoming increasingly crucial. We built OpenBOM to help manufacturing organizations and engineering teams streamline processes and simplify the way to manage engineering and manufacturing data.

If you’re wondering why, when, and how to introduce OpenBOM to your organization, this blog is just for you – we will walk you through it.

Manufacturing Maze – Complexity of Data Management and Product Development

The manufacturing world is complex and built for many silos. With multiple organizations, the need to share data, complex supply chains, numerous design iterations and manufacturing iterations, managing multi-team collaborations, and managing data efficiently becomes a daunting task. Traditional spreadsheet systems and legacy software solutions often fall short in handling this complexity, leading to disjointed information, miscommunication, and inefficiencies.

Top 5 Problems I’ve Heard from Engineering Teams and Manufacturing Companies

After speaking with 1000s of engineers and manufacturing companies, here are 5 problems we’ve heard about.

- Working with files, excels, and multiple legacy systems is inefficient and leads to mistakes.

- The decision process is critical and requires accurate information

- Need to accelerate processes for new product development

- There is a need to mitigate supply chain and compliance risks

- Products live longer, require maintenance and re-fabrication

Modern data management

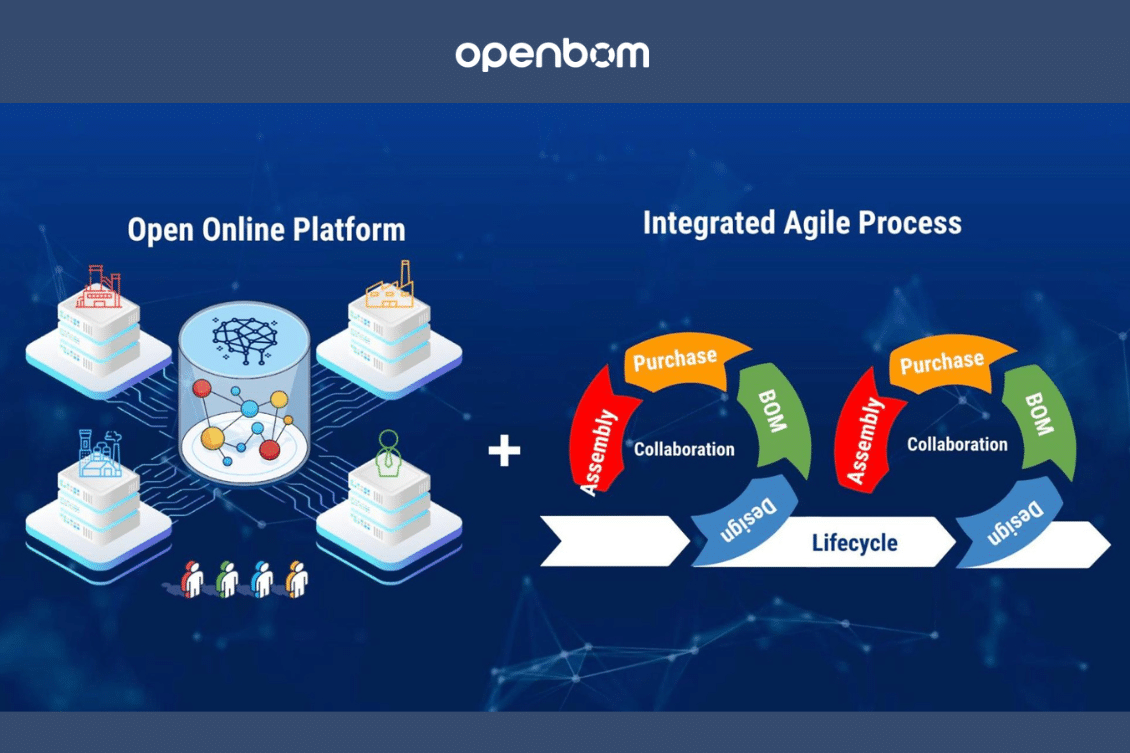

OpenBOM utilizes a set of modern technological solutions to organize a global and online system capable to support a flexible and open data model, real-time data sharing, and scalability to work across multiple organizations. A core of OpenBOM is a graph data model allowing you to build flexible data sets and semantic relationships between data elements.

Agile New Product Development

With the introduction of integrated data management, collaboration, and seamless integration, OpenBOM brings a set of functions that connect a foundational process in any product development organization – engineering to manufacturing. The process became agile and allows you to move fast in short sprints.

Engineering teams, manufacturing companies, contractors, and suppliers can collaborate in real-time, ensuring that everyone is on the same page. By integrating design, procurement, and production processes, OpenBOM helps in reducing the time-to-market. It streamlines iterations, and feedback loops, and ensures a more responsive product development cycle.

Technology and Architecture – OpenBOM Tech Stack and Differentiators

OpenBOM stands out not just for its features but also for its underlying technology:

- Cloud-Native Design: Allows for seamless access anywhere, anytime.

- Open Graph Model: This allows for flexibility and a collaborative environment.

- Real-time Data Sync: Ensures everyone is looking at the most recent data.

- Integration Capabilities: OpenBOM can be easily integrated with other tools – CAD, CRM, ERP and others

- Security Measures: End-to-end encryption ensures data safety.

What do Customers Say About OpenBOM?

The best way to learn about what customers say is to check OpenBOM customer stories and G2 reviews online. Here are a few passages:

“it is right-sized for my company. Filling a niche that MRP systems are not. Other programs are too limited or to cost too much. OpenBOM offers a lot of benefits to a company in a certain range and at a great value.“ – John E, President, Gates Underwater – Read the story

Just as Onshape is a single source of truth for the CAD design, OpenBOM does the same for manufacturing production planning, purchasing, and inventory control. It is a perfect relationship.” – David Rubli, Senior Mechanical Engineer, Xtend Robotics Read the story

From the multi-level product BOM, we create an Order in OpenBOM for our next batch of units. The Quantity Gap (the on-hand inventory) is calculated and the buyers know immediately what we need to buy to complete that order. OpenBOM vendor sources have been pre-defined for each item to smooth the way when supplier shortages are encountered.” – Jackie Wu, CEO – Read the story

OpenBOM Strategy and Implementation Manifesto

Please check out the following slide deck that gives you a set of steps to understand and implement OpenBOM.

Conclusion: Summary and To-Do Actions

OpenBOM offers a compelling solution to tackle the challenges of the modern manufacturing business. We provide solutions for SMBs/SMEs as well as divisions of large enterprises OpenBOM brings teams together with data, people, and processes in a single integrated environment.

Here are your next 5 steps in discovering OpenBOM:

- Learn More: Dig deeper into OpenBOM’s features and capabilities.

- Make a Trial: Experience OpenBOM firsthand by setting up a trial.

- Let Engineers Use It: Encourage your engineering teams to test it out and gather feedback.

- Pitch OpenBOM to Your Boss: Present the benefits and how it can solve current challenges.

- Speak to OpenBOM Sales: Get a comprehensive understanding of pricing, support, and integration possibilities.

REGISTER FOR FREE and check how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.