The engineering bill of materials (EBOM) is a special BOM, which is used by the companies to define all products of how the product is designed and includes all technical specifications of the products. There are so many definitions of EBOM. You can check some of them in my Beyond PLM blog here and here. I also recommend you check Jos Voskuil’s blog about EBOM here.

EBOM is a fundamental data structure to define all design and engineering aspects of the product. OpenBOM provides a comprehensive set of features and functions to manage it in a flexible, yet automatic way where it is possible.

1- Quantity based Bill of Materials and Data Structure

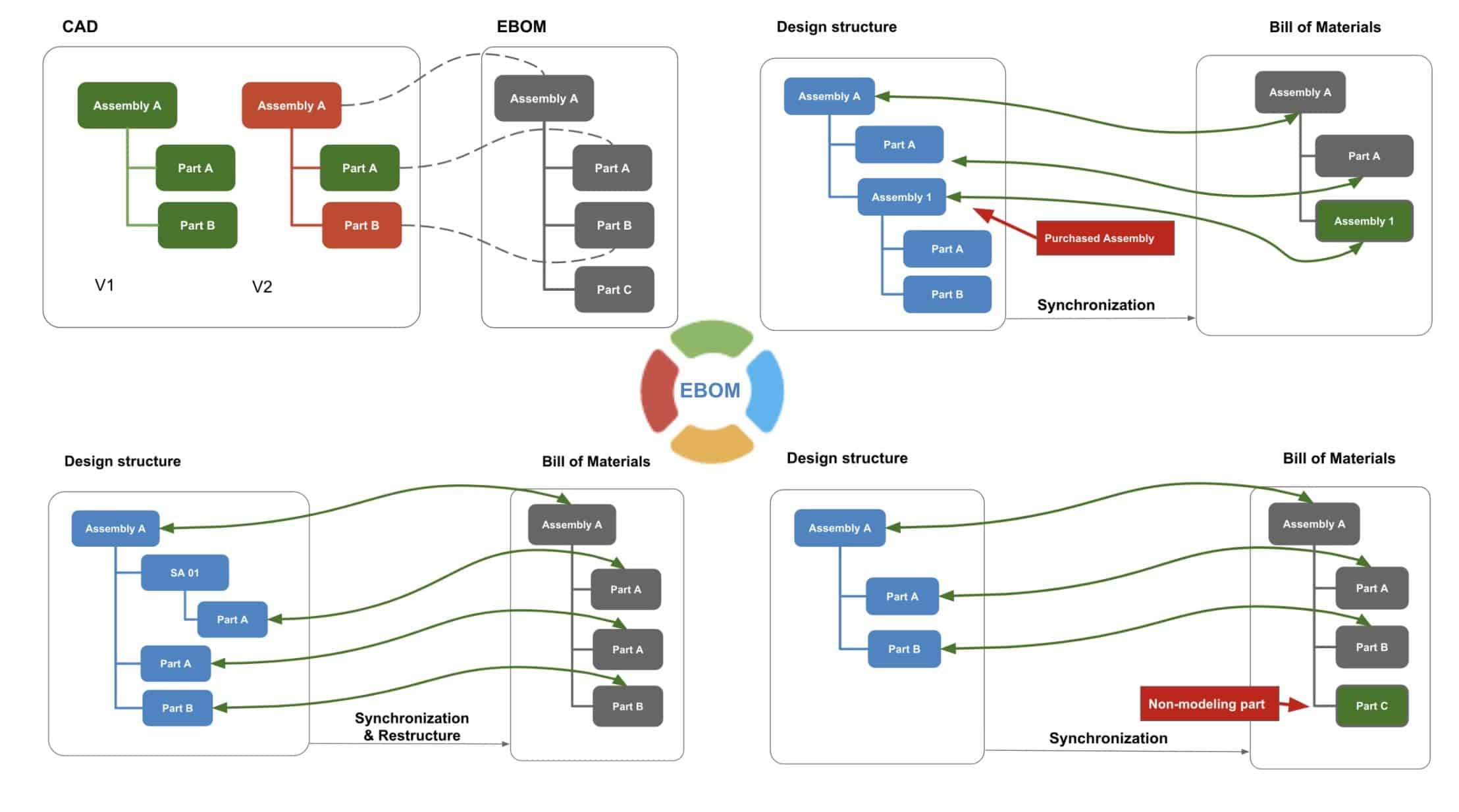

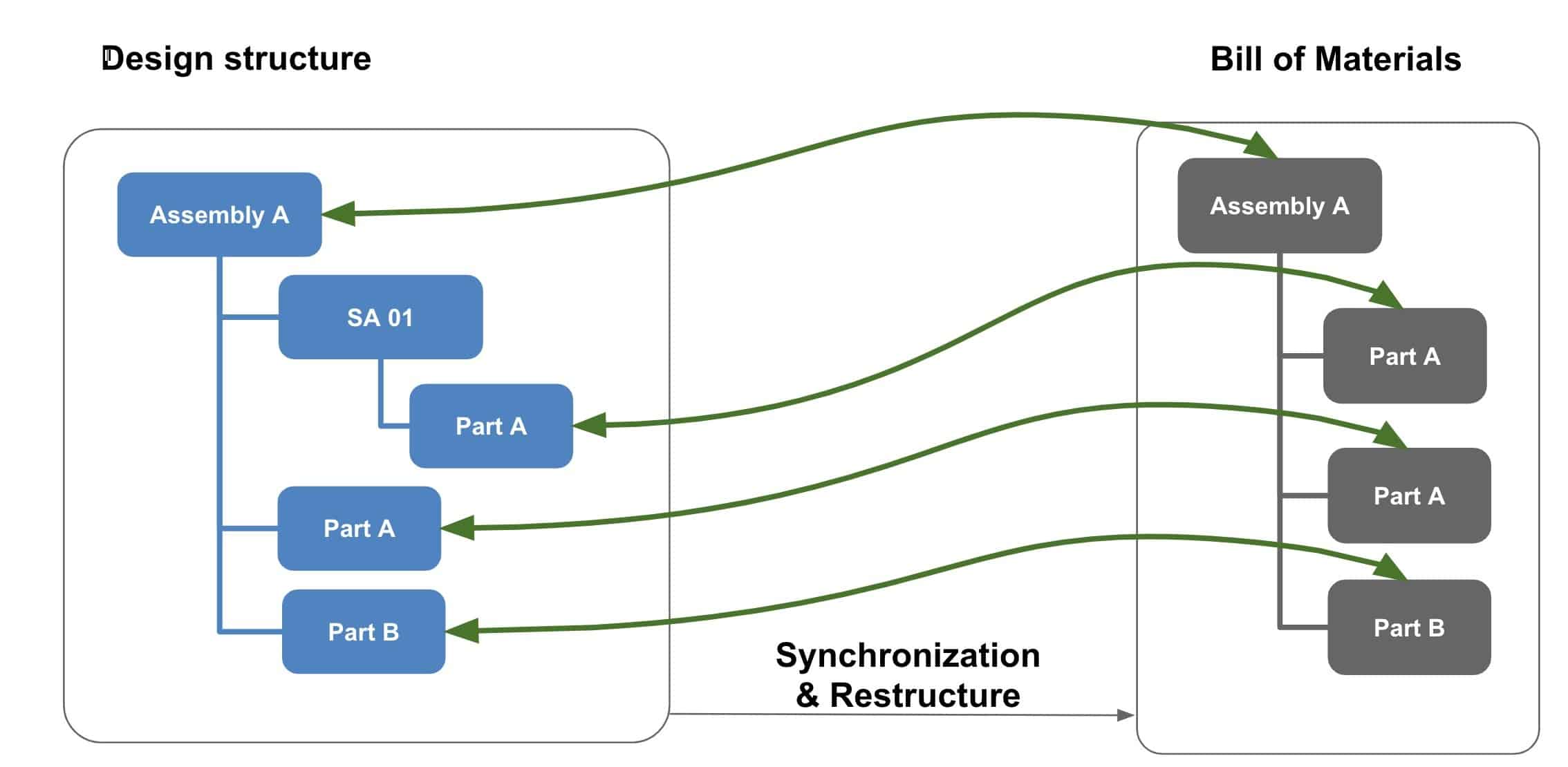

A typical CAD (especially MCAD structure is instance-based. EBOM turns instance-based structure into a Quantity-based. OpenBOM one-click function in CAD integrations automatically collects the information from CAD design and creates the OpenBOM Reference-Instance model capable to hold both item definitions as well as for instance information. OpenBOM simultaneously can support both quantity and instance-level BOM. OpenBOM Flattened BOMs can turn such a structure in the flat list for purchasing purposes. Companies are also restructuring EBOM to make it modular for future use.

2- Multi-disciplinary product definition

EBOM is not about mechanical parts only. Mechanical design is often a foundation of a multi-disciplinary product structure, which includes electronics and software. The last one is a big challenge these days for many manufacturing companies. OpenBOM granular BOM definition allows constructing a BOM from multiple elements created from different data sources, which makes it a place to connect all pieces of information together.

3- Top-down and Bottom-up

A typical story is how EBOM is created from a CAD system. While this is still a process that happens with many companies, we also can see many situations when companies are working on the products and start from BOM or recombine multiple existing components and modules in the resulted EBOM. You can get all support to do both in OpenBOM.

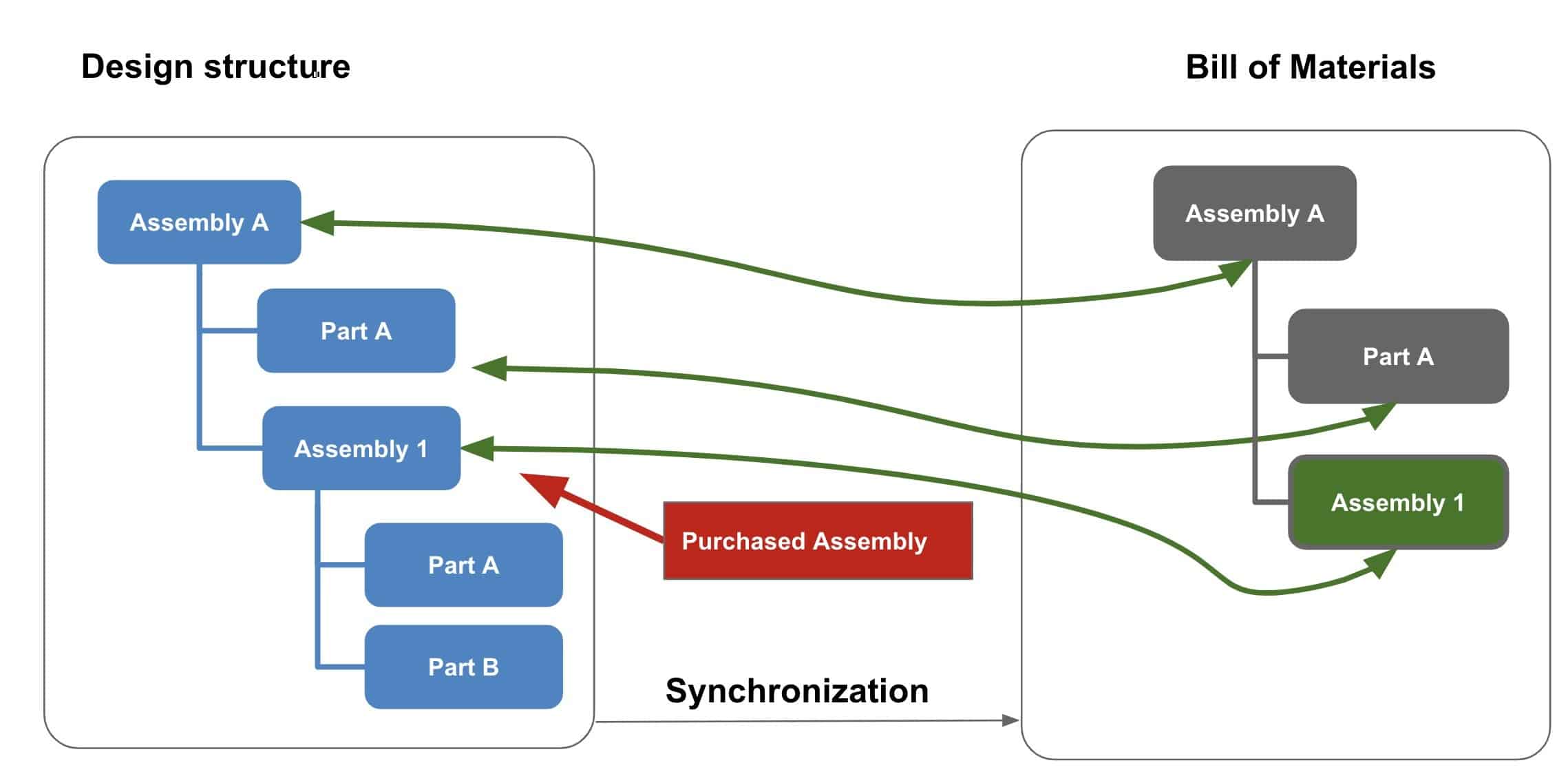

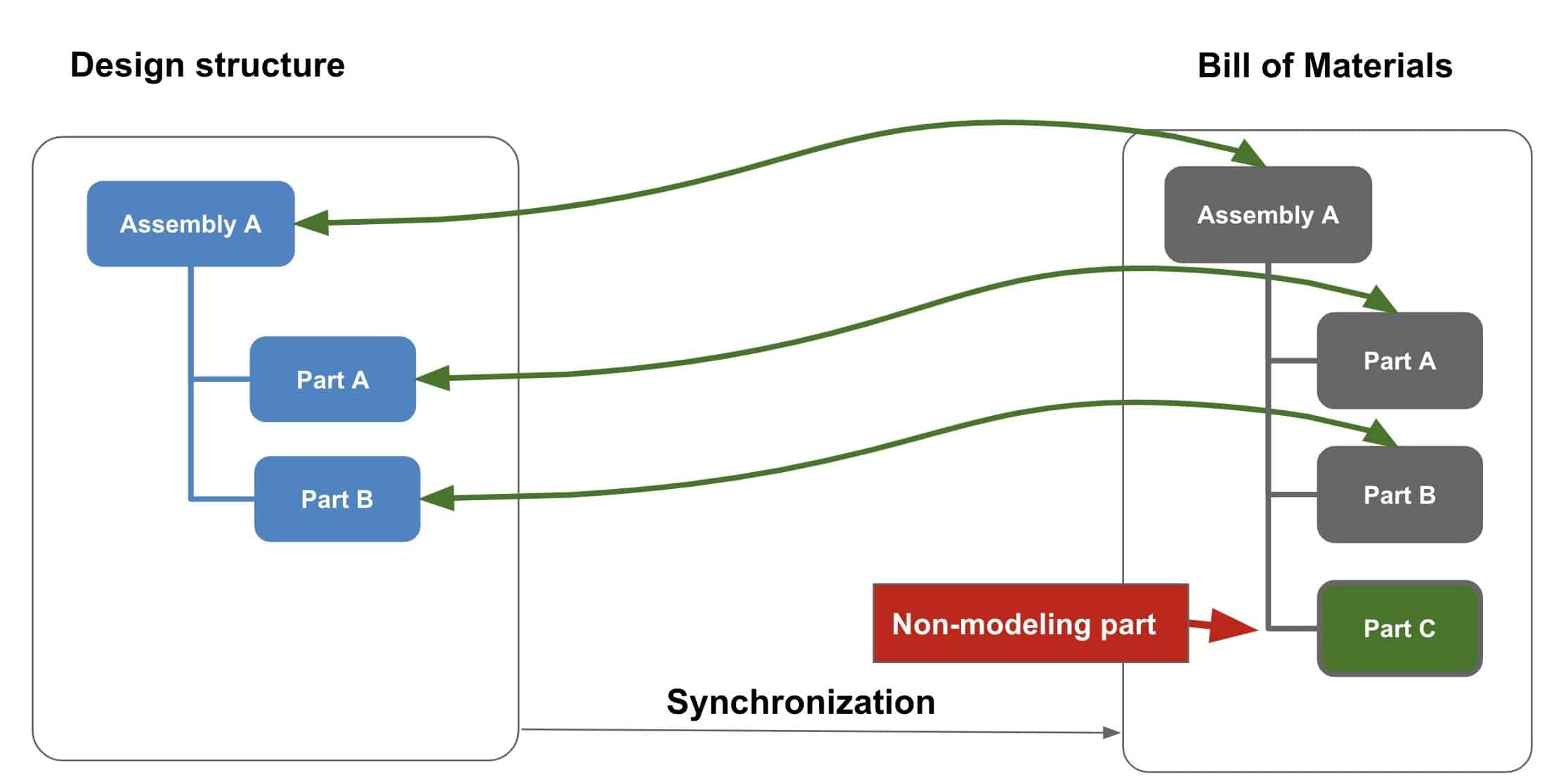

4- Purchased assemblies, parts, and non-model items

Typically CAD structure keeps all information about assemblies, even so, some of these assemblies are purchased as a whole. When it happens, it is very important to provide a way to exclude the parts of these assemblies from the EBOM.

All OpenBOM CAD add-ins support a feature to exclude parts of purchased assemblies from BOM as well as to add specific materials and parts that are not modeled in CAD in EBOM and keep a subset of EBOM information synchronized with CAD system.

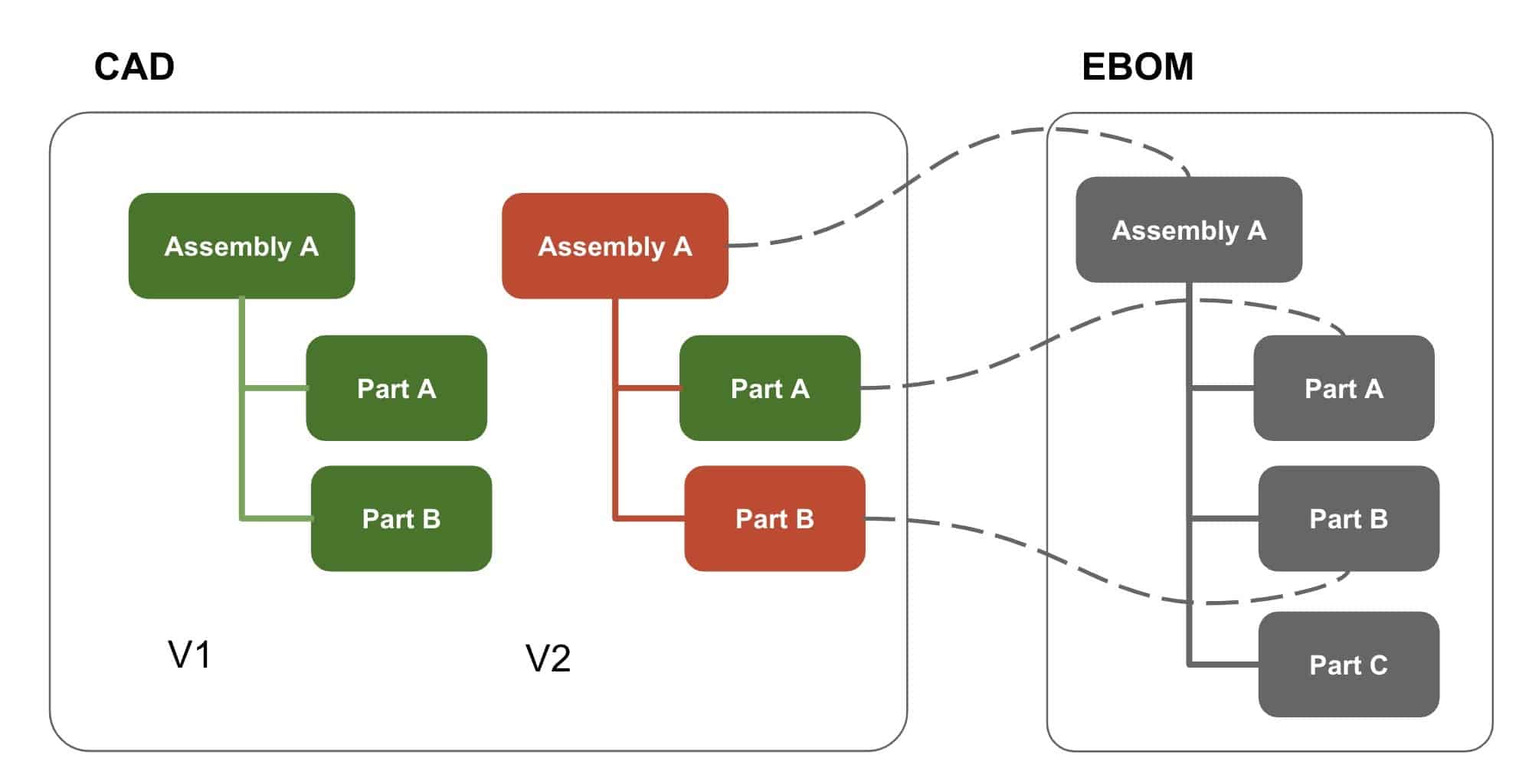

5- BOM Revisions

Changes are the most constant thing in engineering and manufacturing. Yet, you need to have a baseline everyone in your team and company can use. EBOM revisions are the way to do so. While EBOM revisions are not the same CAD file versions? It is because design changes can happen more often and not be reflected in EBOM that shared with the broad engineering team, production planners, procurement, contractors, and suppliers. OpenBOM change management and revision mechanism is granular and allows you to keep track of all changes in the BOM as well as create immutable Revisions as a baseline for the change management process.

6- Real-time collaboration

EBOM is true teamwork. To have a team of engineers working together on the same BOM, getting access to the same information is the key. OpenBOM gives you unique collaborative functions allowing to the team to have simultaneous access to the information on a global scale and between organization. It doesn’t matter where you located and what company your work for, OpenBOM will give you a “share” function to access BOM with granular access – you will see what you need and when you need it.

Conclusion

EBOM management is a complex process that requires flexible data management combined with efficient integration and collaboration. OpenBOM CAD add-ins and data sharing, combined with a flexible data model is key to support the EBOM management process.

Check what OpenBOM can do for you – REGISTER FREE

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.