The manufacturing industry is slowly but surely switching from selling products to selling services.

This fundamental change is being driven by many innovative technologies such as IoT and Industry 4.0 as well as increased demand for environmentally friendly products, recycling, as well as the demand of the manufacturing companies to offer more custom products.

While each of these factors deserves at least one dedicated article, I’d like to speak about what all of these demands have in common – and that it is…the ability to manage Bill of Materials for serial numbers of the products, to keep them handy and be able to track what is the BOM for each of these products that are sold to specific customers.

Why create a Serial BOM?

While it might sound like a simple thing to do, when it comes to the management of engineering and manufacturing data, many systems have very little to offer. Almost all PLM companies were developed back in the days when serialization and maintenance BOM were only relevant for a few very exclusive industries – aerospace and defense. This is not true anymore. Today every manufacturer is looking at how to build connected products and how to create “as-built” and “as-maintained” BOMs.

In my blog today, I will demonstrate to you a quick technique on how you can use OpenBOM to manage Serial Numbers, Bill of Materials for Serial Numbers, and how to maintain a connected list of Serial Numbers in OpenBOM.

Here is a simple step-by-step instruction.

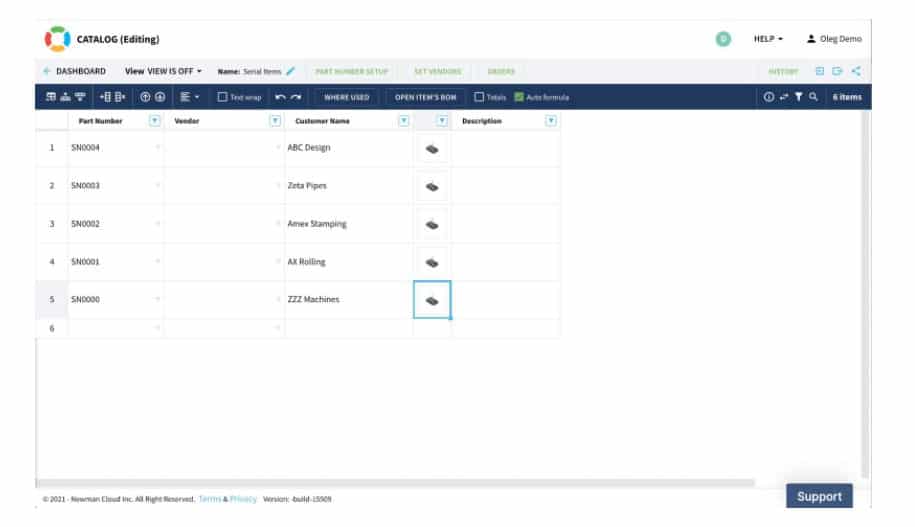

1- Catalog For Serial P/Ns.

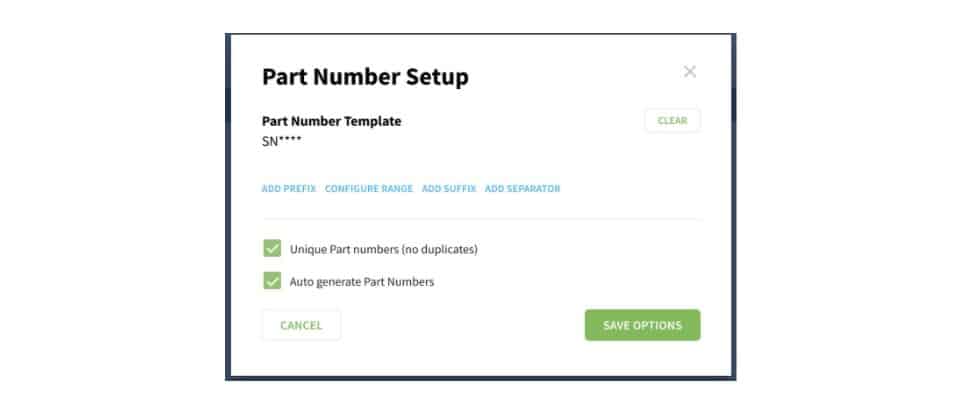

To create a catalog for serial numbers of your product a catalog will be used to add an item with S/N. Each item in this catalog will represent a serial number and will be generated automatically using OpenBOM’s Part Number Setup.

Here is the setup2- Add Reference Property to Item Master Catalog(s)

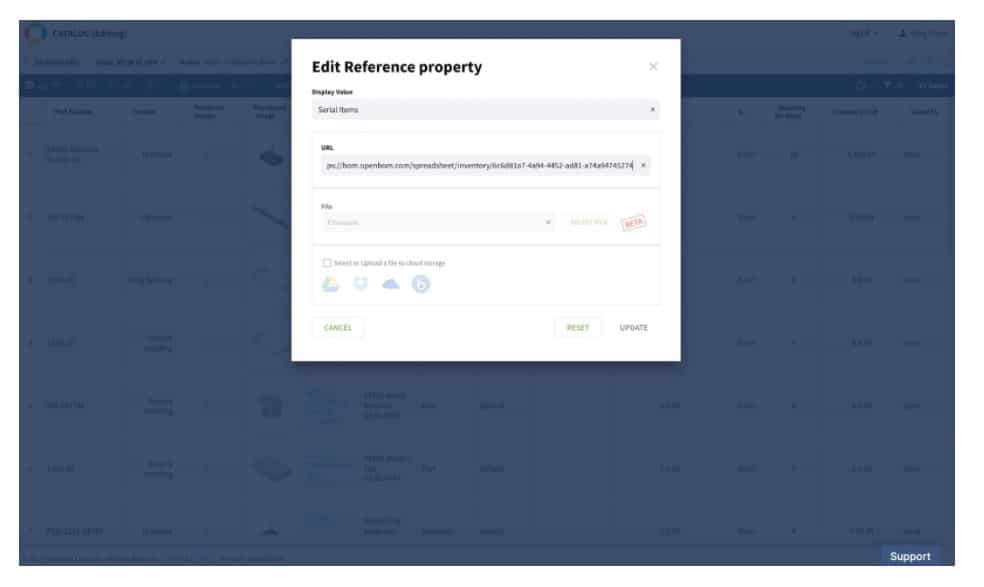

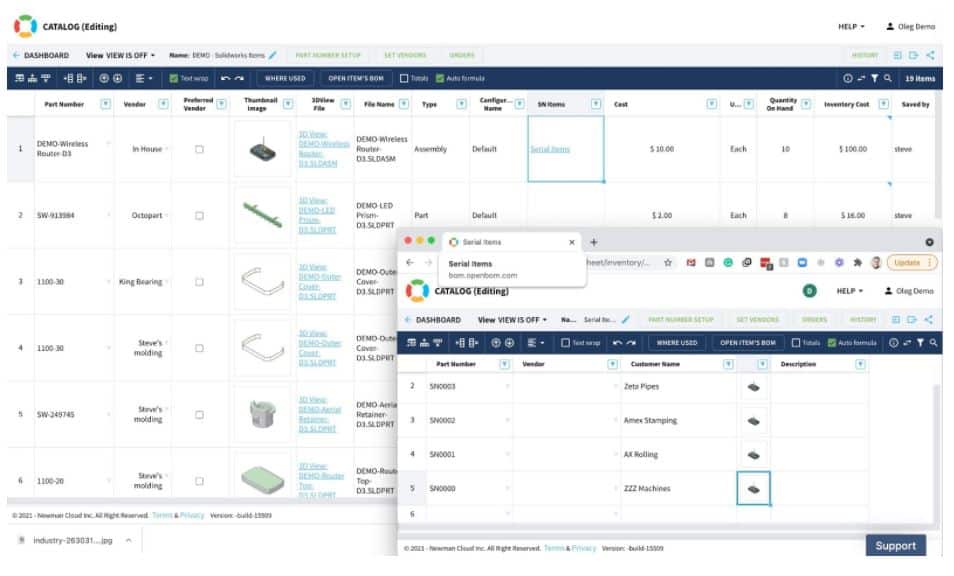

OpenBOM allows you to manage items in the catalogs. You might create one or many catalogs in OpenBOM. Catalogs allow you to classify and add data about any item in OpenBOM. The catalog you created during the previous step will be linked to the item catalog for end items. Keep in mind that you need to use the Reference property type to connect the link from serial number catalogs to the item catalog with assemblies and other engineering items.3- Link Item in the catalog to Serial Numbers catalog

The last step is to connect these catalogs. You do that by simply editing the value of the link in the engineering items catalog and placing a link to the Serial Numbers catalog. Once done, you can navigate to the serial number catalog and add the next serial number. You can also do it by using the REST API using programming language if you want to build a better integration process.

Tip. You can create a copy of the BOM used for the product and to use the generated SN (Part Number) from the catalog of serial P/Ns. By doing it this way you will have an easy way to keep track of serial numbers and maintain serial BOMs.

Conclusion

For many companies these days, managing serial numbers and As-Built and As-Maintain BOMs is a matter of life and death. It is the only way to follow regulations and to maintain the traceability of products for maintenance. Especially, if you’re still managing BOMs using Excel spreadsheets. Just imagine how much of a mess you will create by attempting to manage S/N using “yet another Excel” and combine all these pieces.

OpenBOM gives you an easy way to solve the problem of BOM Serialization and management of Serial Numbers easily and simply.

Check how OpenBOM can manage serial numbers and BOM, register for FREE, and start your 14-day trial today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.