The procurement of components is one of the most important activities that stands between design and production. About 70% of parts in every product are either purchased or outsourced. With such a high volume of procurement, to make it happen smoothly is one of the fundamental requirements of successful product development and a foundation of product delivery on time.

Unfortunately, from my experience, when it comes to medium-size manufacturing companies, this function is very sub-optimal. The engineering and procurement teams are liver their own lives and connected by crappy and fragmented Excel files.

In such a situation, how can you think about optimization of the product cost, selecting contractors and suppliers as well as following delivery of purchases?

OpenBOM helps you tremendously to control procurement by establishing a super-efficient design for the purchasing process. The foundation of the process is product data (catalogs and BOMs) describing exactly what parts and components must be outsourced and track cost and delivery.

Today, I want to share how can you do it in OpenBOM. In this video, I share a few options on how to collaborate with multiple vendors, share information and compare cost.

You might decide to share or not to share the BOM or catalog with vendors. OpenBOM gives you the flexibility to do it in multiple ways.

1- Keep a copy of the BOM for each vendor/contractor. It is simple and easy, but might not be an optimal way. It creates a redundancy, but completely isolate everything you do. You can share data online (OpenBOM share) or export/import using Excel.

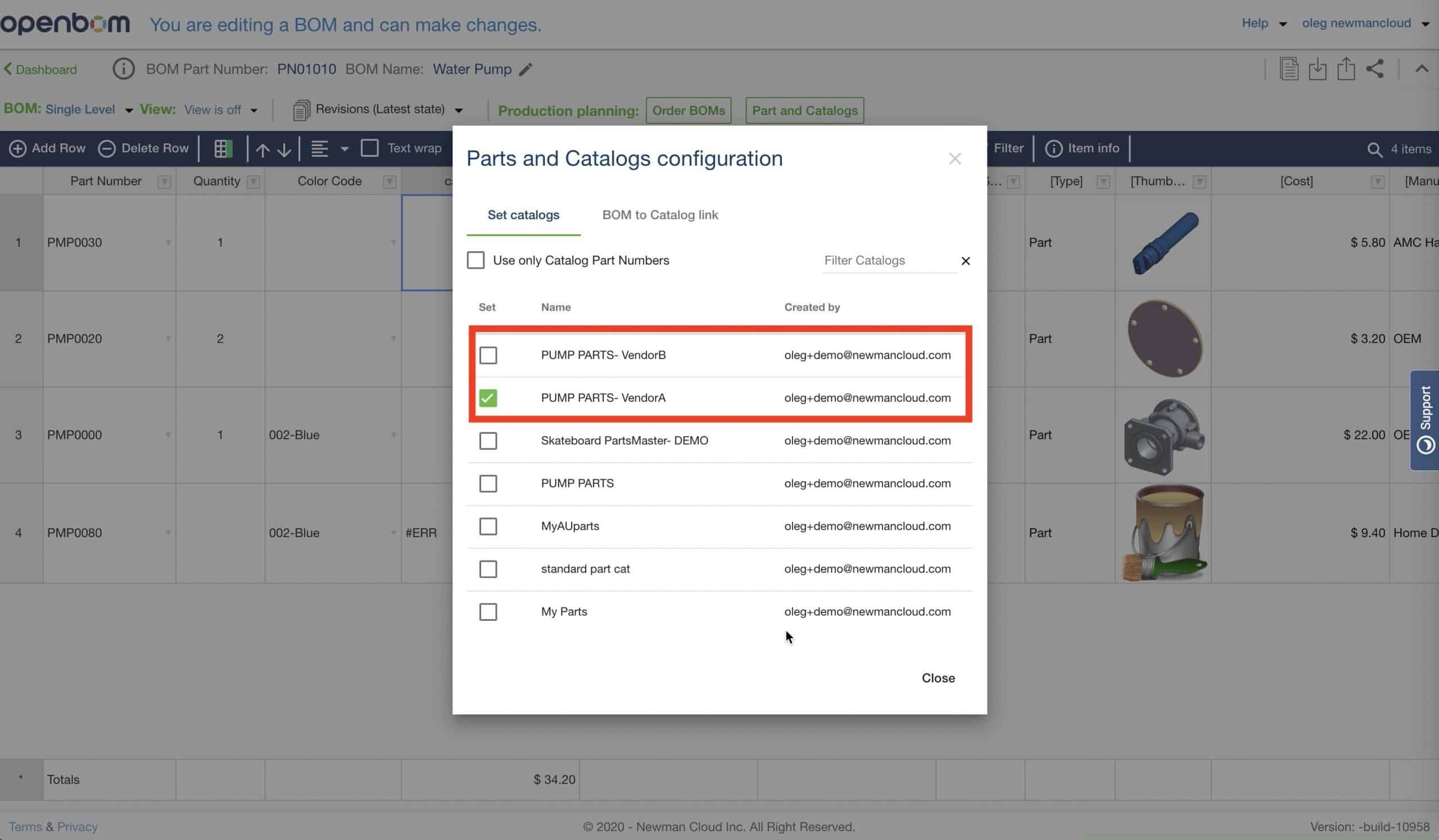

2- Create multiple catalogs to work with each vendor or vendor setup. In such an option, you create catalogs to keep vendor-specific data (cost, lead time, etc.). By assigning a specific catalog to a BOM you can use the same formula to calculate the cost and compare it.

Check the video for more details.

There are a few other options. A user-defined view is one of them. I will talk about it in my next video.

Conclusion.

OpenBOM gives you a super-efficient option to organize data bout products, control information about parts, cost, supplier and other vendors and share it with the right people at the right time.

No more Excel hell and emails with spreadsheets. No more craziness of uncertainty and delayed product batches. No more cost going out of control.

All these things can be done using OpenBOM.

Register for OpenBOM user subscription later today

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Image by Mudassar Iqbal from Pixabay

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.