In today’s fast-paced business environment, the ability to streamline processes and manage data effectively is critical to staying competitive. This is especially true for processes that require efficient data transfer such as D2P (design to production), which requires initiating a downstream process, where efficient management of data handover is essential for successful project completion. In this article, we will discuss how the management of downstream processes can be improved by streamlining data handover from Onshape to OpenBOM.

OpenBOM Integrated App for Onshape

Onshape is a cloud-based computer-aided design (CAD) software that allows users to create and share 3D models, drawing and perform design releases. OpenBOM is a cloud-based PLM software that allows users to manage BOM structure and organize an efficient procurement process by managing inventories, RFQs, and Purchase Orders.

To manage a downstream process efficiently, these two software systems can be integrated to enable seamless data transfer from Onshape to OpenBOM.

OpenBOM integration with Onshape provides very simple yet configurable support for transferring data. However, a simple data “push” is not what is needed for efficient process management. In fact, engineers are looking for a flexible and granular process allowing them to transfer information about parts and assemblies when they are ready without waiting for an entire project to be completed.

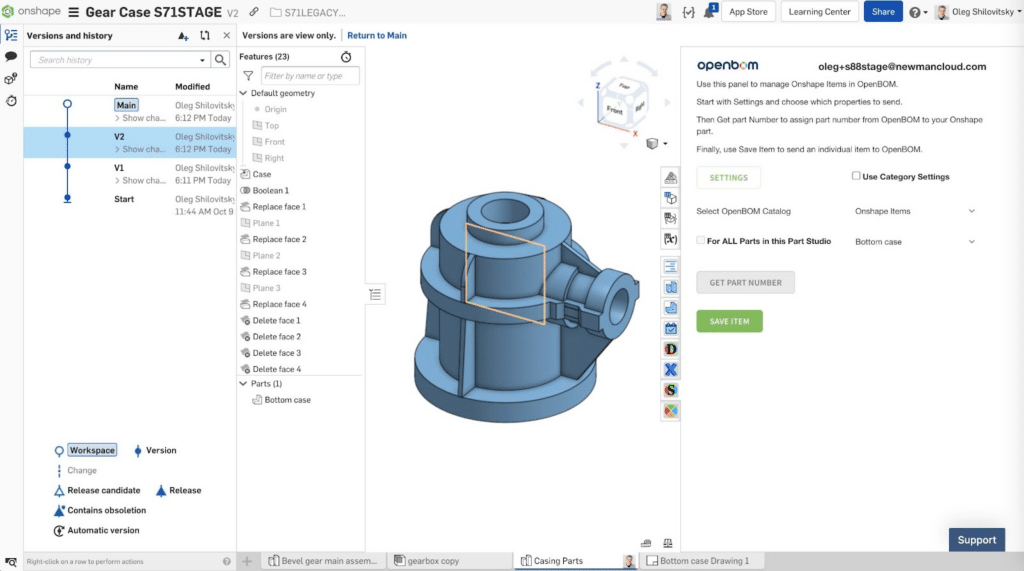

Once the design of a specific part of the sub-assembly is completed in Onshape and the version (or release) is done, OpenBOM can help you to transfer the data using the built-in integration feature. This feature allows users to transfer items and BOM data directly from Onshape to OpenBOM with a few clicks of a button. All metadata, including all derivative files (STEP, STL, PDFs) are automatically transferred too. This saves time and reduces the risk of errors associated with manual data entry and file saving.

In OpenBOM, the BOM data can be further refined and optimized for downstream processes. This ensures that the data is easily accessible and understandable for downstream teams, such as procurement and production. People responsible for purchasing process can define vendors, and identify and create RFQs and Purchase Orders.

Video Demonstration – Save a Released Part to OpenBOM

In my video, I demonstrate new improvements in OpenBOM for Onshape allowing to save a specific released version of a part (or assembly) directly from Onshape to OpenBOM with a single button click.

Conclusion:

Management of downstream processes can be greatly improved by streamlining data handover from CAD to PLM environments such as Onshape to OpenBOM. By capturing data correctly in Onshape, and transferring it seamlessly to OpenBOM, businesses can improve the efficiency and accuracy of their downstream processes and save a lot of engineering time. Early visibility of engineering data can improve supply chain management. Overall it saves time, reduces the risk of errors, and ultimately leads to better project outcomes.

REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.